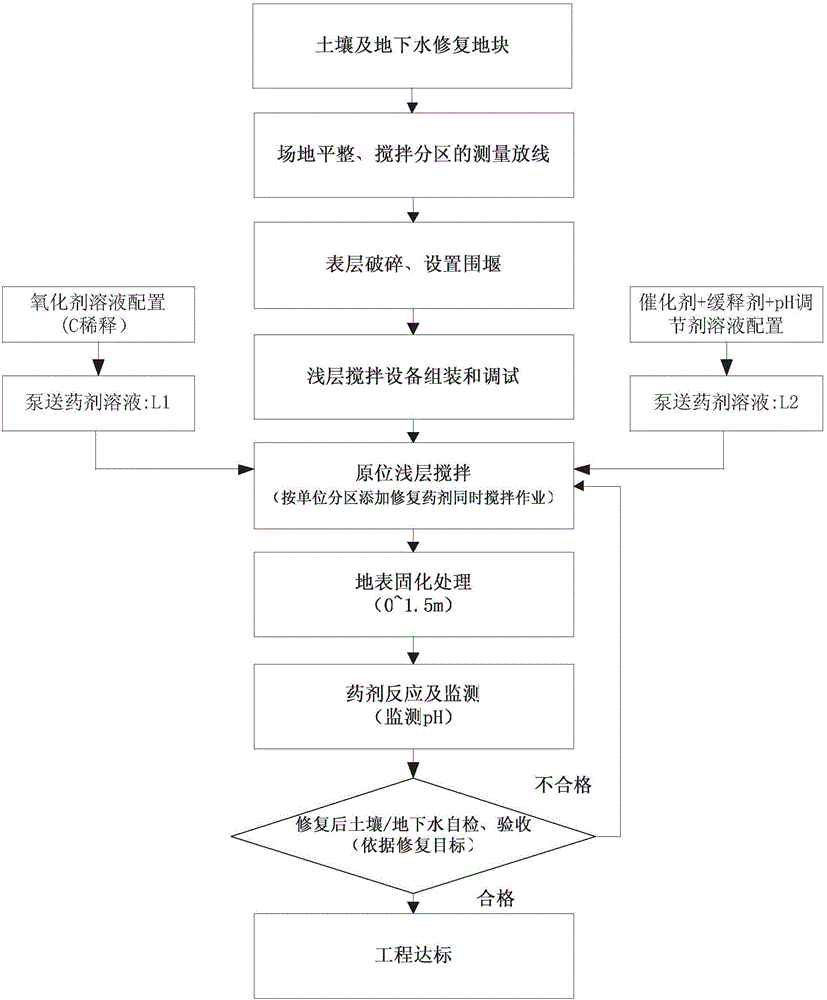

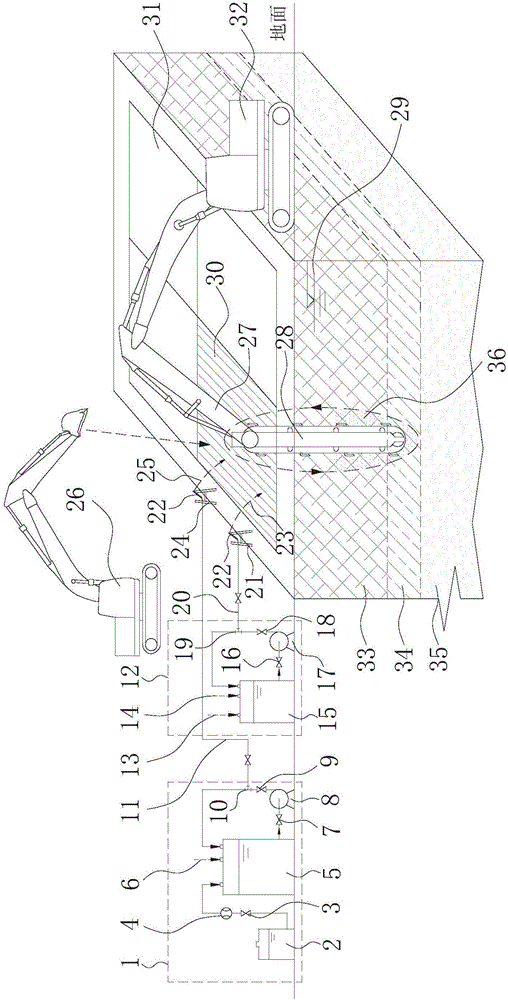

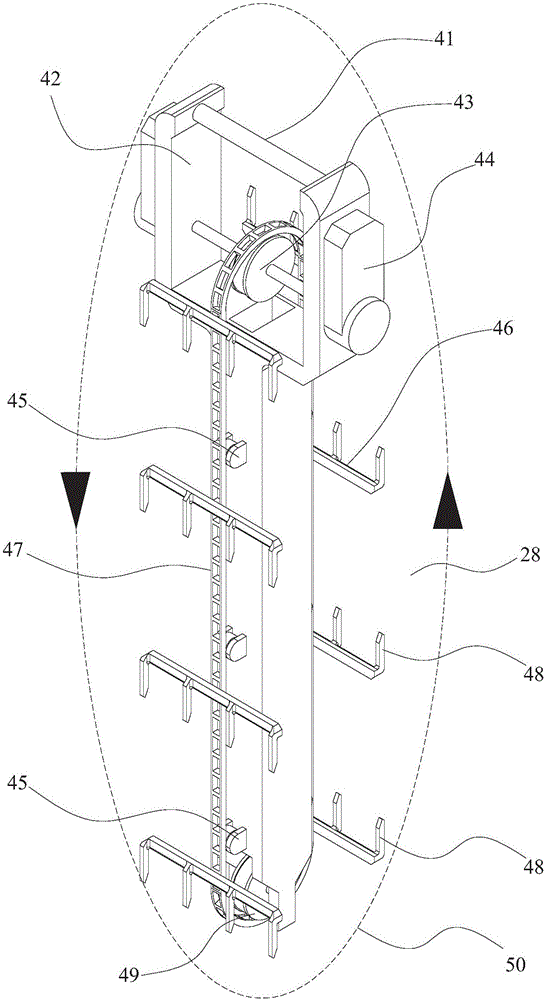

Double-liquid shallow-mixing in-situ chemical oxidation repair method for contaminated soil and groundwater

An in-situ chemical oxidation and polluted soil technology, which is applied in the field of in-situ chemical oxidation repair of contaminated soil and groundwater with two-liquid shallow stirring, can solve the problems of large agent loss, uneven injection of agents, high decomposition rate, etc., and reduce natural decomposition Loss, meet the operating radius parameters, the effect of shortening the repair cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This project is a soil and groundwater restoration project for a chemical plant in Nanjing. The soil restoration project volume is 258,000 square meters, and the groundwater restoration project volume is 170,000 square meters. The construction period requires 150 days. The maximum depth of shallow soil pollution at this site is 4m, and there are mainly miscellaneous fill and silty clay layers, and the groundwater is shallow (about 1m) and abundant. The target pollutants in shallow soil / groundwater are VOCs / SVOCs organic compounds such as chlorobenzene, benzene, p- / o-nitrochlorinated benzene, etc.

[0079] In order to solve the problem of shallow pollution in the in-situ chemical oxidation remediation project, 11% of the soil remediation engineering volume and 8% of the groundwater remediation engineering volume in the project adopted the shallow layer agitation in-situ chemical oxidation process, of which the shallow agitation process About 87% of the soil and groundwat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com