High-pressure jet injection system and method for soil remediation agent

A soil remediation and high-pressure jet technology, which is applied in the restoration of polluted soil, etc., can solve the problems of destroying the soil structure, difficulty in ensuring uniform and effective injection of remediation agents, time-consuming and labor-intensive, etc., to achieve strong pertinence and facilitate absorption and reaction , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

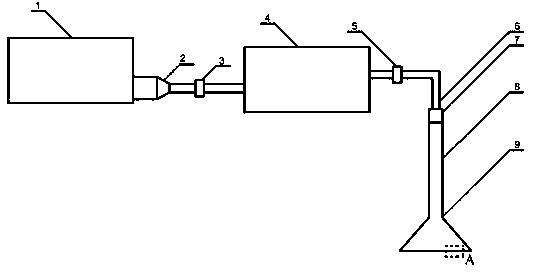

[0036] Embodiment 1: as figure 1 As shown, a high-pressure jet injection system for soil remediation agents includes a dispensing system, a pressure supply system and a liquid injection system connected in sequence. The stainless steel quick joint 2 communicates with the inner cavity of the dispensing station 1; the pressure supply system is a speed-regulating high-pressure liquid injection pump 4, and the liquid inlet port of the speed-regulating high-pressure liquid injection pump 4 communicates with the stainless steel quick joint 2 through the infusion pipeline I, and the infusion pipeline I The inlet valve 3 of the high-pressure liquid injection pump is arranged on the top, and the liquid outlet end of the speed-regulating high-pressure liquid injection pump 4 is provided with a high-pressure liquid injection pipe 6 communicating with the speed-regulating high-pressure liquid injection pump 4. The high-pressure liquid injection pipe 6 is provided with a high-pressure injec...

Embodiment 2

[0037] Embodiment 2: as figure 1As shown, a high-pressure jet injection system for soil remediation agents includes a dispensing system, a pressure supply system and a liquid injection system connected in sequence. The stainless steel quick joint 2 communicates with the inner cavity of the dispensing station 1; the pressure supply system is a speed-regulating high-pressure liquid injection pump 4, and the liquid inlet port of the speed-regulating high-pressure liquid injection pump 4 communicates with the stainless steel quick joint 2 through the infusion pipeline I, and the infusion pipeline I The inlet valve 3 of the high-pressure liquid injection pump is arranged on the top, and the liquid outlet end of the speed-regulating high-pressure liquid injection pump 4 is provided with a high-pressure liquid injection pipe 6 communicating with the speed-regulating high-pressure liquid injection pump 4. The high-pressure liquid injection pipe 6 is provided with a high-pressure inject...

Embodiment 3

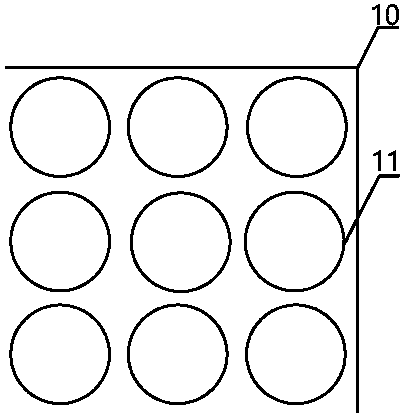

[0050] Embodiment 3: The structure of the soil remediation agent high-pressure jet injection system in this embodiment is basically the same as that of the soil remediation agent high-pressure jet injection system in Example 2, except that the diameter of the injection microhole 11 is 5 μm;

[0051] Soil remediation agent high-pressure jet injection method:

[0052] (1) Prepare the soil remediation agent (the soil remediation agent is Fenton’s reagent) and water according to the mass ratio of soil remediation agent and water of 1:50, and add the soil remediation agent to the dispensing station of the dispensing system middle;

[0053] (2) According to the soil pollution situation and soil properties, set the injection pressure value of the speed-regulating high-pressure injection pump to 200MPa so that the injection depth of the soil remediation agent is 100% of the remediation depth;

[0054] (3) Contaminated soil injection repair: Open the inlet valve of the high-pressure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com