Capillary wastewater treatment and desalination equipment and method

A technology for wastewater treatment and desalination equipment, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high cost and difficulty in the treatment of high-salt and high-concentration organic wastewater , to achieve the effect of reducing the processing burden, responding thoroughly, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

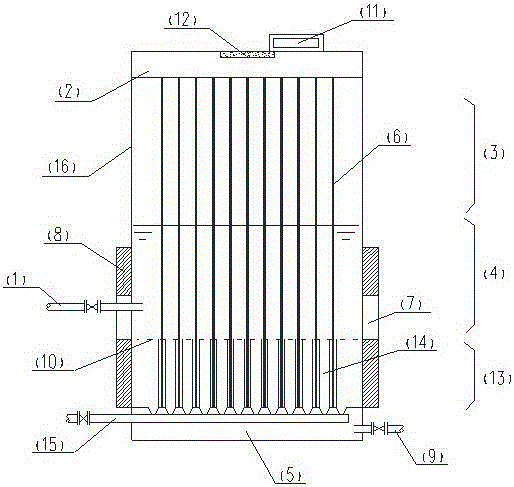

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] figure 1 It is a schematic diagram of the cross-sectional structure of the capillary wastewater treatment and desalination equipment.

[0028] like figure 1 As shown in the figure, the inside of the capillary wastewater treatment and desalination equipment is an orderly and uniformly arranged capillary-like tube 6, its structure is cylindrical or square, and the material of this structure is a corrosion-resistant, high-temperature-resistant and high-pressure resistant polymer membrane material .

[0029] The inside of the equipment is composed of a concentrated water area 13, an immersion area 4, a soda-water mixing area 3, a top vacuum area 2 and a clean water area 5. The top vacuum area 2 and the clear water area 5 are connected through a capillary 6, while the steam-water mixing area 3 and the top vacuum area are connected. 2 completely iso...

Embodiment 2

[0046] The capillary wastewater treatment and desalination equipment proposed by the present invention is used to treat the wastewater of a pesticide factory. The pesticide wastewater is high-concentration and high-salt wastewater. The influent water quality is as follows: pH: 9-10, COD: 1452 mg / L, NH3- N: 217 mg / L, salt content: 13.2%. After being treated by the capillary wastewater treatment and desalination equipment proposed by the present invention, the COD removal rate is about 70-85%, the NH3-N removal rate is 60-70%, and the salinity is reduced to below 2-3%. Compared with the commonly used wastewater physicochemical treatment process combined with membrane technology, under the same treatment effect, the treatment cost is reduced by 20-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com