Method for treating wood/bamboo and wood/bamboo product

A treatment method and metal technology, which is applied in the field of wood/bamboo products and wood treatment, can solve the problems of easy fire, easy to be eaten by insects, easy to deform, etc., and achieve the effect of improving performance and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

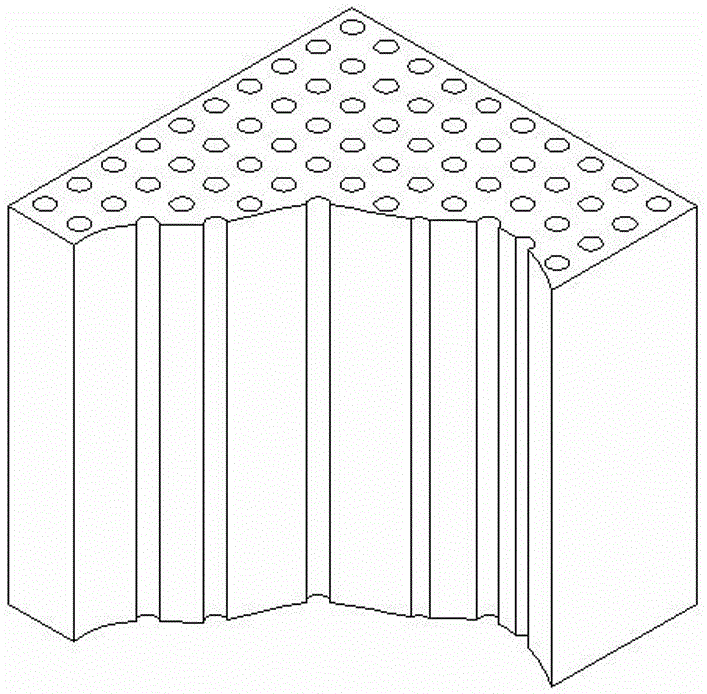

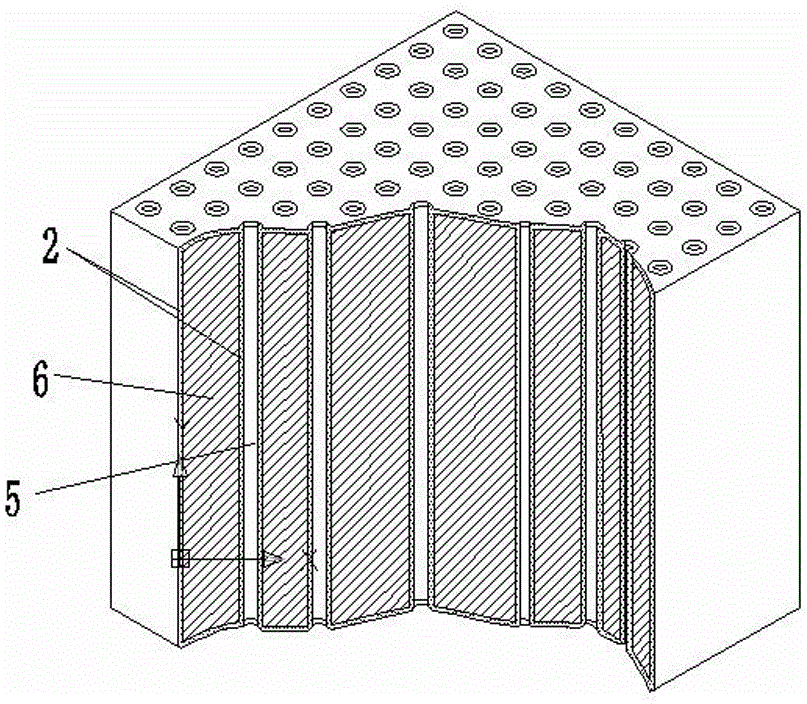

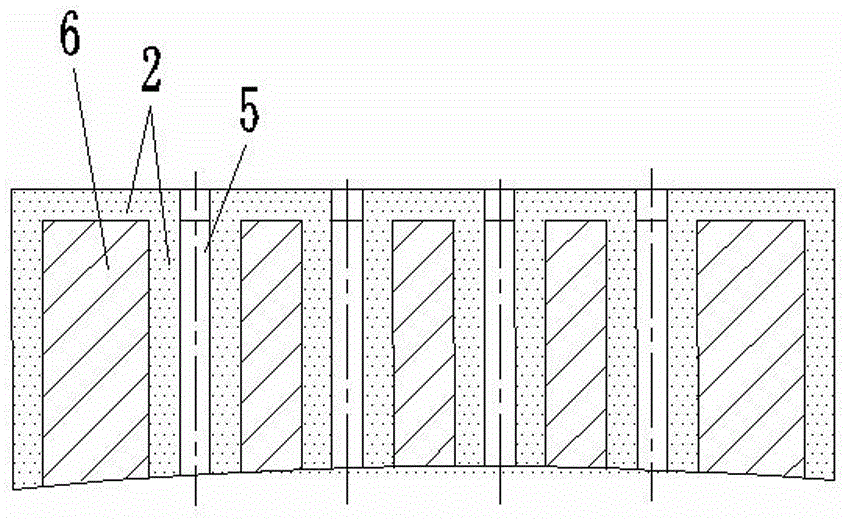

[0021] The invention makes full use of the self-limiting and follow-up properties of atomic layer deposition, and uses ALD to treat wood, wood products, bamboo and bamboo products, so that the surface of wood, bamboo and their products and the surface of the fiber hole inner wall grow metal oxides Gas barrier film 2. For the convenience of description, wood, wood products, bamboo, and bamboo products are collectively referred to as substrates.

[0022] Taking the example of setting an aluminum oxide metal oxide gas barrier film on the substrate as an example, the specific description is as follows:

[0023] Clean the surface of the substrate so that there is no impurity on the surface of the substrate, at least the end face of the substrate is exposed, so that the precursor will not be blocked from entering the fiber hole. Put the substrate into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com