Semiconductor package and method of packaging the same

A packaging method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as easy oxidation of copper, failure of copper ball 24 spherical shape, high electric burning temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

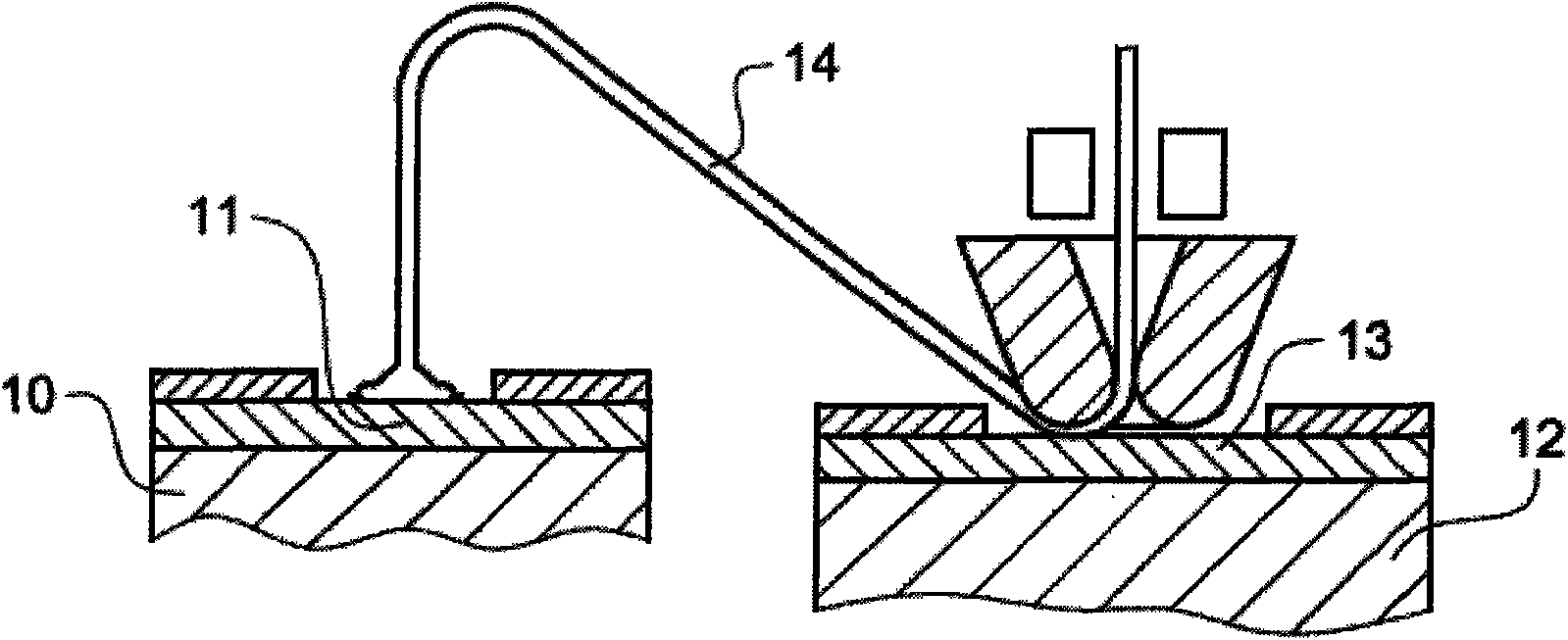

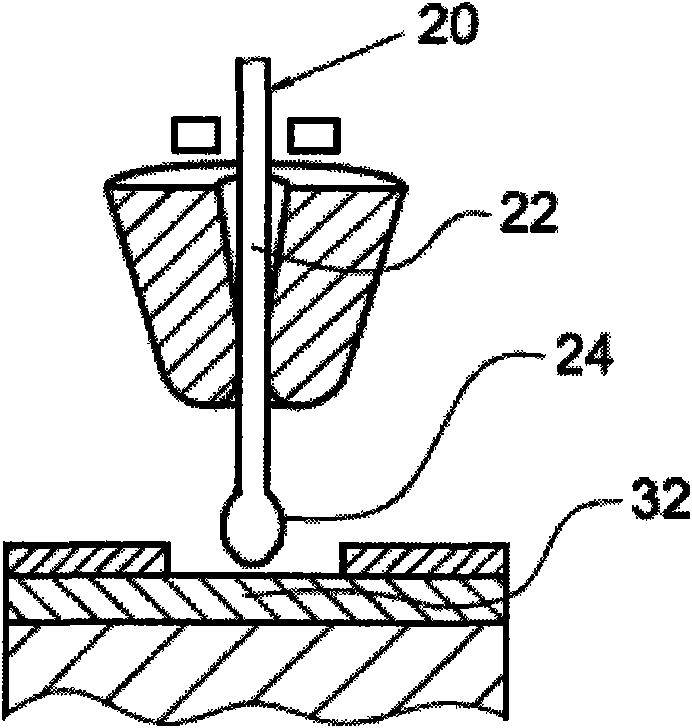

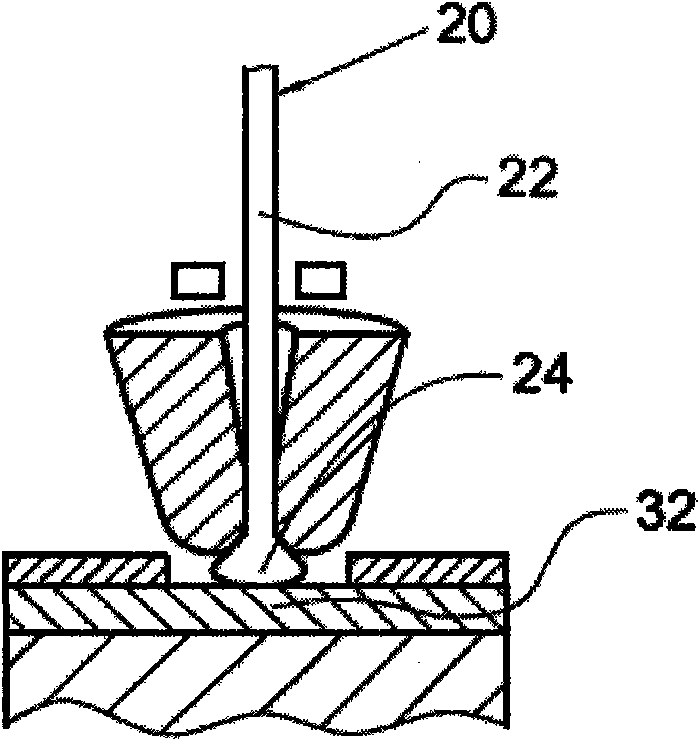

[0054] refer to Figure 5 to Figure 12 , which shows an embodiment of the semiconductor packaging method of the present invention. refer to Figure 5, providing a carrier 112 having an upper surface 113 and a lower surface 114 opposite thereto. On the upper surface of the carrier 112 is arranged a wafer 110 , wherein the wafer 110 has an active surface 115 and a rear surface 116 opposite thereto. Pads 132 (such as aluminum pads) are disposed on the active surface 115 of the die 110 . refer to Figure 6 , in this embodiment, the brazing wire 120 is provided by the wire bonding machine 102 , and the brazing wire 120 includes the linear portion 122 . refer to Figure 7 , make the inert gas 140 pass around the wire end 123 of the linear portion 122, and pass through an electric firing process, such as a discharge process of an electronic burning ball device (electrical flame-off; EFO) 104 with high voltage, to The wire end 123 of the wire portion 122 forms a spherical portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com