Lithium metal battery, negative electrode, electrolyte and preparation of negative electrode

A technology of lithium metal battery and electrolyte, applied in the field of electrolyte and negative electrode of lithium metal battery, can solve the problems of electrolyte performance loss, electrode corrosion, metal negative electrode consumption, etc., and achieve the effect of improving cycle performance and Coulomb efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

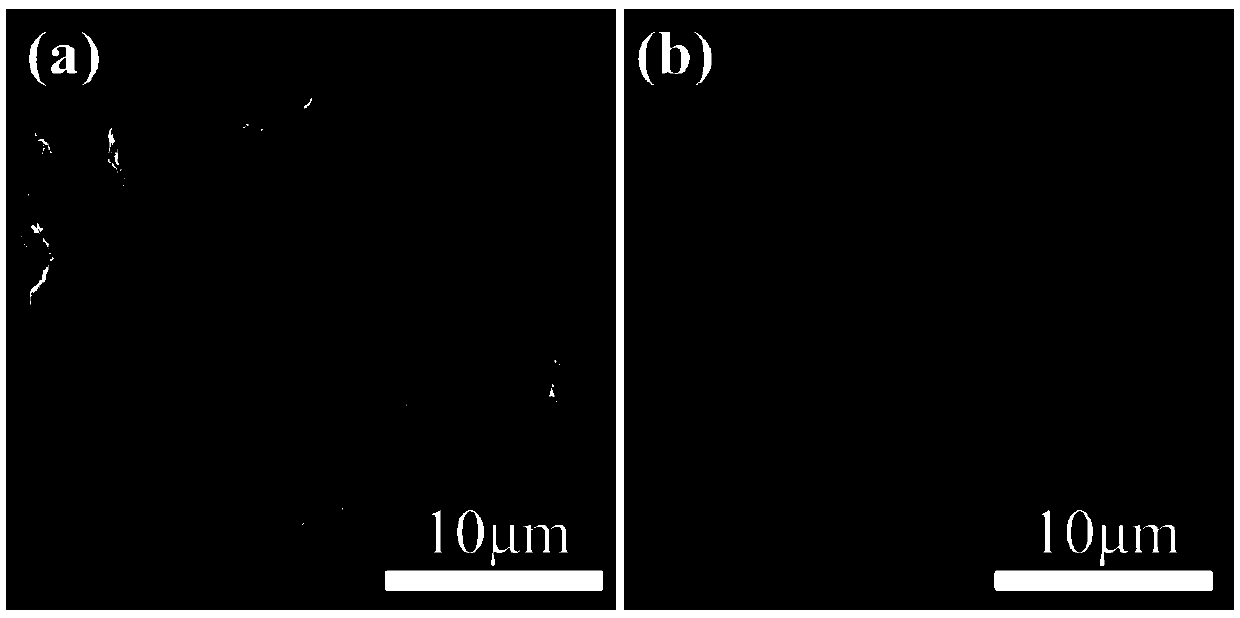

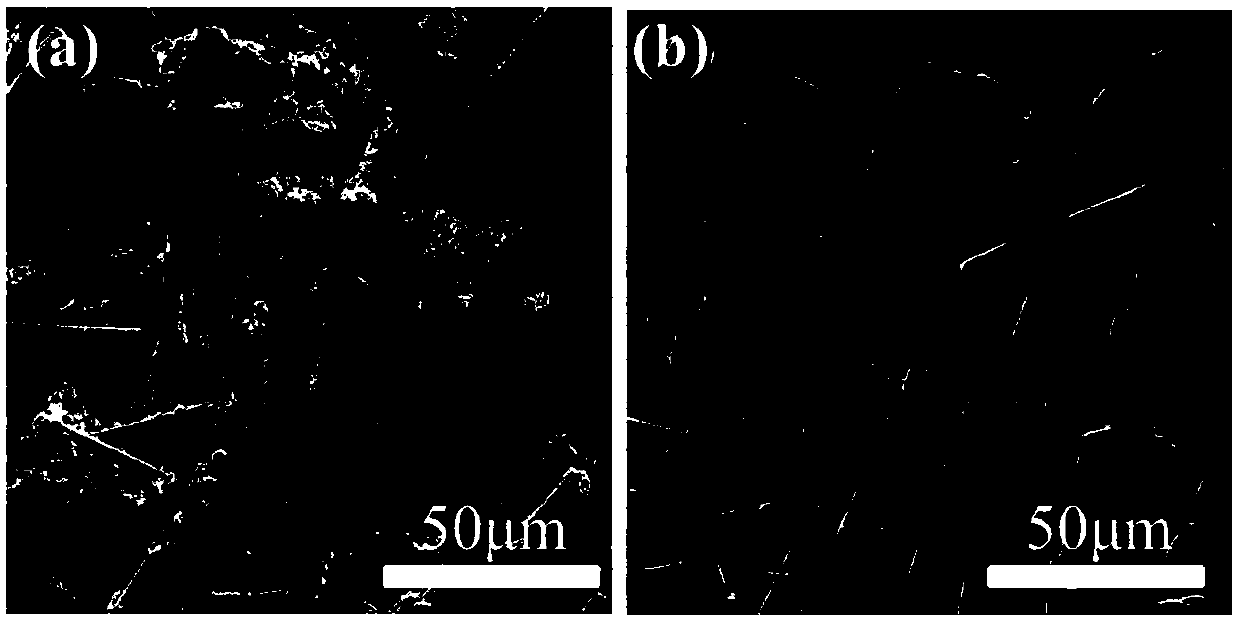

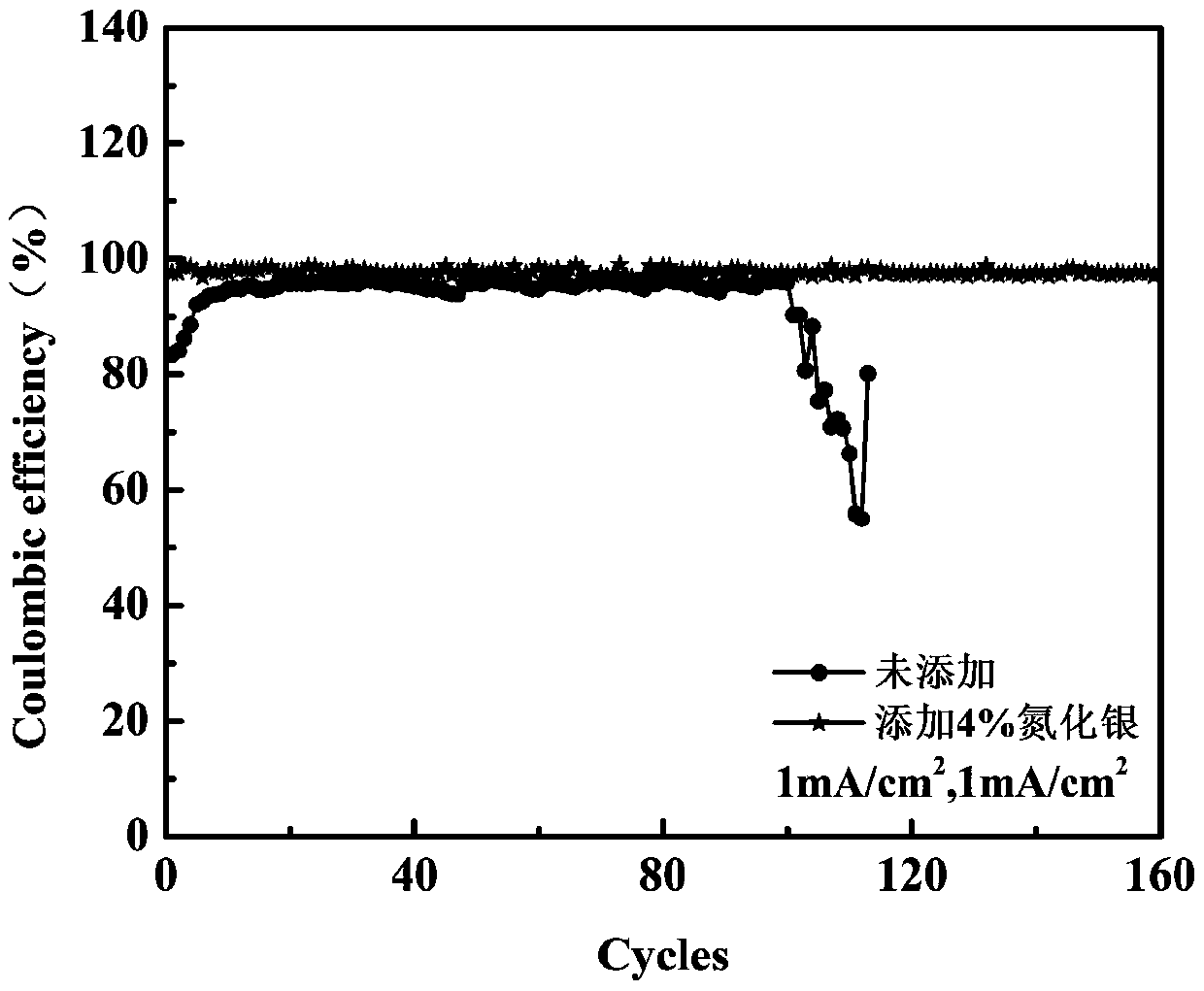

Embodiment 1

[0073] Copper foil with a diameter of 13mm is used as the deposition object (working electrode), and a metal lithium sheet is used as the counter electrode, and a diaphragm is used to separate the working electrode from the counter electrode; 2% fraction of insoluble copper nitride (insoluble particles) 1M LiTFSI / DOL:DME (volume ratio=1:1) containing 1%wt LiNO 3 It is the electrolyte; the electrolyte for soaking the counter electrode is 1 MLiTFSI / DOL:DME (volume ratio=1:1) containing 1%wt LiNO 3 For the electrolyte (the only difference is that 2% insoluble copper nitride is not added). The diaphragm is made of GF / D glass fiber, and a 2032 button lithium-ion battery (half battery) is assembled for charge and discharge cycle tests. The electrolyte (1MLiTFSI / DOL:DME (volume ratio = 1:1) containing 1%wt LiNO without adding insoluble particles 3 is the electrolyte) for comparison, the two batteries are at 1mA / cm 2 Charge and discharge current density and 1mAh / cm 2After continuo...

Embodiment 2

[0077] Copper foil with a diameter of 13mm is used as the deposition object (working electrode), and a metal lithium sheet is used as the counter electrode, and a diaphragm (GF / D glass fiber) is used to separate the working electrode from the counter electrode; Electrolyte) containing 2% zinc nitride and 3% copper nitride (insoluble particles) uniformly dispersed into 1M LiTFSI / DOL:DME (volume ratio = 1:1) containing 1%wt LiNO 3 for the electrolyte. The electrolyte solution for soaking the counter electrode is 1M LiTFSI / DOL:DME (volume ratio=1:1) containing 1%wt LiNO 3 For the electrolyte (the only difference is that no insoluble particles are added). With no insoluble particles added to the electrolyte as a comparison, a 2032 button lithium-ion battery was assembled, and the separator was made of GF / D glass fiber, and the charge-discharge cycle test was carried out. With the same electrolyte, without adding insoluble particles as a comparison, the two batteries are at 1mA / c...

Embodiment 3

[0079] The carbon paper with a diameter of 13mm is used as the deposition object (working electrode), and the metal lithium sheet is used as the counter electrode, and the working electrode and the counter electrode are separated by a diaphragm; the working electrode side of the diaphragm (the electrolyte soaking the working electrode) contains a mass fraction of 5% aluminum nitride 1M LiTFSI / DOL:DME (volume ratio = 1:1) containing 1%wt LiNO 3 for the electrolyte. The electrolyte solution for soaking the counter electrode is 1M LiTFSI / DOL:DME (volume ratio=1:1) containing 1%wt LiNO 3 As the electrolyte (the only difference is that no insoluble particles are added), compared with no addition in the electrolyte, a 2032 button lithium-ion battery is assembled, and the diaphragm is made of GF / D glass fiber, and the charge-discharge cycle test is carried out. Two batteries at 1mA / cm 2 Charge and discharge current density and 1mAh / cm 2 After continuous charge and discharge under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com