High-carbon preservative outdoor bamboo floor

A bamboo floor, high-carbon technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of easy peeling, cost increase, and unfavorable service life of bamboo flooring, so as to save production processes, prevent adverse effects, reduce The effect of dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

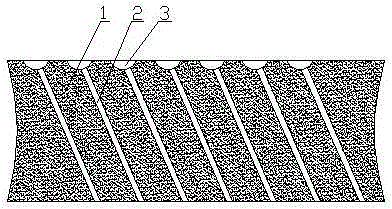

[0020] As shown in the attached figure: a high-carbon anti-corrosion outdoor bamboo floor, including the bottom plate body 1, the floor body 1 is a high-carbon anti-corrosion bamboo veneer, no need to lay an additional film layer, which not only saves the production process, but also effectively reduces bulges and other phenomena; the upper surface of the floor body 1 is provided with an anti-skid groove 3, and the left and right sides of the floor body 1 are inwardly recessed arc structures, which can deal with the expansion phenomenon of the floor body 1 due to changes in temperature, moisture content and other factors, ensuring There will be no swelling phenomenon; the floor body 1 is obtained by dipping bamboo chips after high-temperature carbonization and then pressing at high temperature, and has good anti-corrosion and water-proof performance; the density of the floor body 1 is 1.5g / cm 3 , the density is higher, the number of air holes in the floor body 1 can be reduced,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com