Four-shaft combined precise drive steering engine device

A steering gear, precision technology, applied in the direction of projectiles, self-propelled bombs, offensive equipment, etc., can solve problems such as complex structure, high maintenance cost, impact of return clearance, etc., to improve the control range, facilitate disassembly and maintenance, and increase control effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

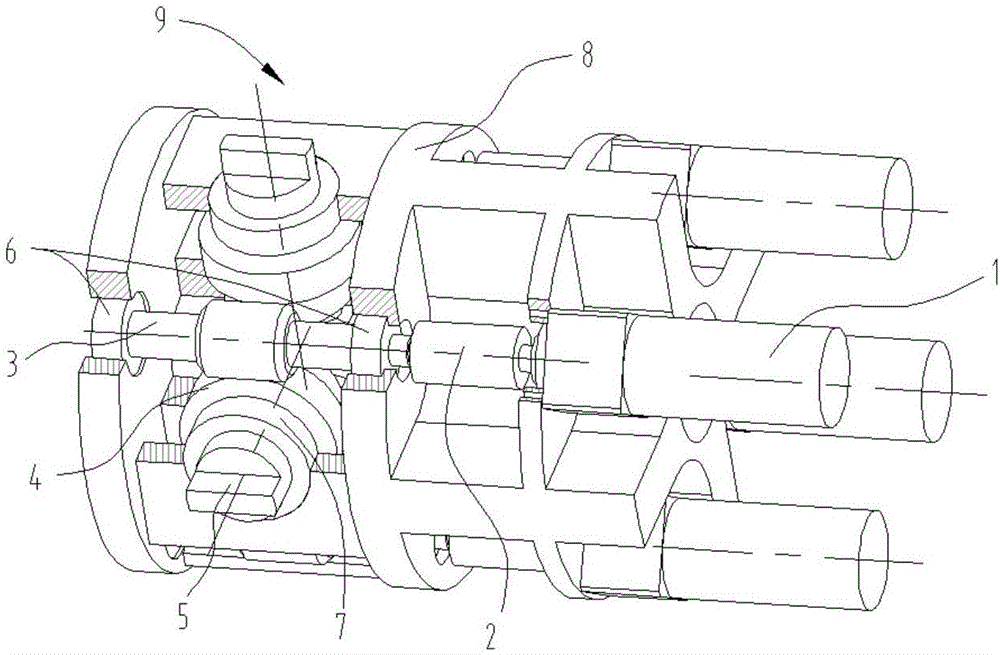

[0021] According to the attached figure 1 Specific embodiments of the present invention are further described in detail.

[0022] It includes a motor drive system (1), a rudder shaft drive unit (3-5) and a steering gear main structure (8);

[0023] The main structure of the steering gear (8) is used to connect the steering gear device inside the main body of the portable missile; the main structure of the steering gear (8) is a three-layer structure, and the top layer is respectively provided with four flange holes along the circumference for fixing four sets of Motor drive system (1); the first bearing hole is set at the position corresponding to the flange hole in the middle layer, and the first bearing is set inside, the upper end of the worm 3 passes through the first bearing bearing to connect to the coupling 2, and the coupling 2 is connected to the motor drive system ( 1) at the output end, the bearing is arranged in the bearing hole, and the bearing hole is used to li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com