Brushless DC motor simulation control method and brushless DC motor simulation system

A brushless DC motor and control method technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of unstable rotational speed, difficult and efficient control, torque ripple of brushless DC motors, etc., and achieve strong inhibition , the effect of improving acceleration performance and improving driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

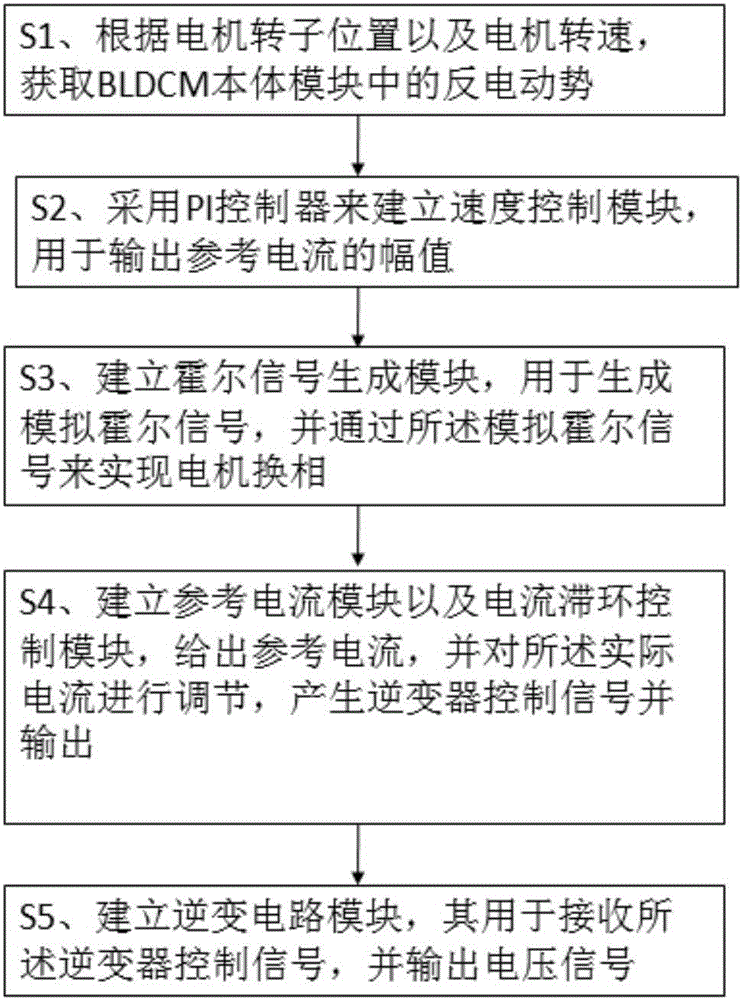

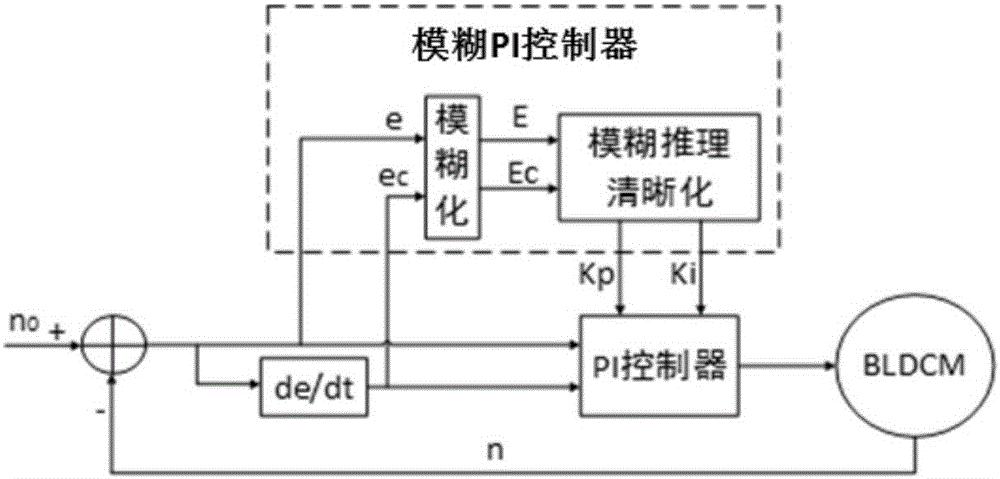

Method used

Image

Examples

Embodiment 1

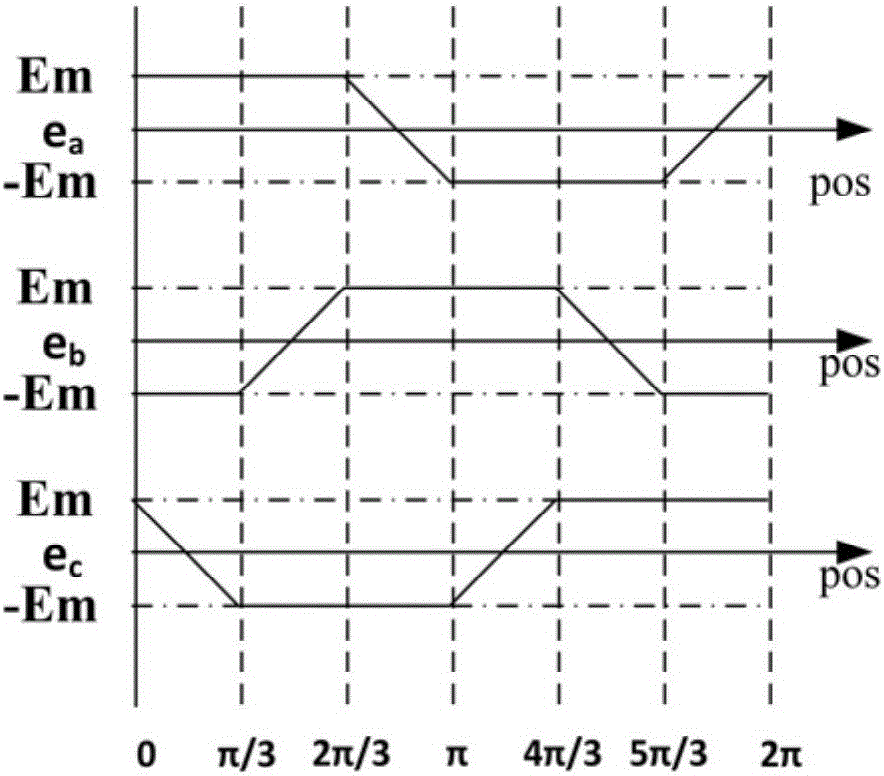

[0052]The brushless DC motor is composed of stator three-phase windings, permanent magnet rotor, rotor position detector, etc. The motor in this embodiment is preferably a permanent magnet brushless DC motor with two-phase conduction, three-phase six-state star connection, and for Two-phase conduction three-phase six-state permanent magnet brushless DC motor, in order to facilitate the analysis of its mathematical model and the characteristics of electromagnetic torque, the following assumptions are made to simplify the analysis: 1) Regardless of the armature reaction, its air-gap magnetic field The induced back electromotive force is approximately regarded as a trapezoidal wave at an electrical angle of 120°; 2) Neglecting the influence of cogging and commutation process, the armature conductor is continuously distributed on the inner surface of the stator; 3) Neglecting the saturation of the motor magnetic circuit, eddy current and hysteresis loss are not considered ; 4) Both...

Embodiment 2

[0097] Figure 5 A brushless DC motor simulation system capable of realizing the above control method is shown, which includes:

[0098]BLDCM body module 1 that can simulate the operating characteristics of real motors;

[0099] a speed control module 2, which is used to output the magnitude of the reference current;

[0100] Hall signal generating module 3, which is used to generate analog Hall signals, and realize motor commutation through the analog Hall signals;

[0101] A reference current module 4, which is connected to the speed control module and the Hall signal generating module, for providing a reference current according to the magnitude of the reference current and the analog Hall signal, and outputting the reference current;

[0102] A current hysteresis control module 5, which is linked to the reference current module, is used to receive the reference current and the input actual current, and adjust the actual current to generate and output an inverter control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com