Production process of powder special for wafers

A special powder and crisp tube technology, which is applied in the production process of the special powder for crisp tube, can solve the problems of the special powder for crisp tube, etc., and achieve the effects of good economic benefits, clear lines and increased market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In the present embodiment, the preparation method of crispy tube special powder is as follows:

[0016] 1) Wheat blending: the wheat with a wet gluten content of 30.0%±0.5% and a stability time of 3 minutes is cleaned and removed by 3 sieves, 2 dozen and 2 stone removal processes;

[0017] 2) Moistening: Moisten the wheat cleaned in step 1), and the moisture content of the wheat is 15.0±0.3%;

[0018] 3) Grinding: Grinding, sifting, and clearing the wheat after step 2), and analyzing the physical and chemical indicators and the content ratio of glutenin and gelatin of each powder road flour, the results are shown in Table 1;

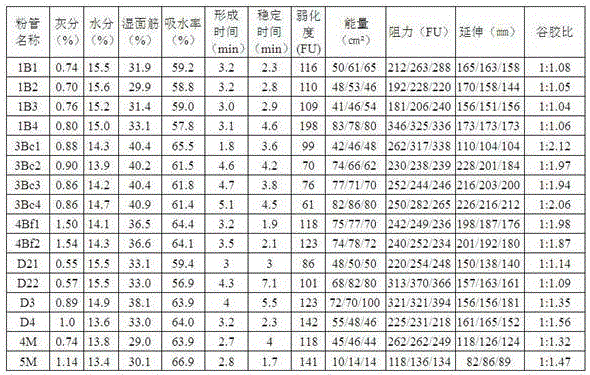

[0019] Table 1 Comprehensive analysis of flour quality

[0020]

[0021] According to the comprehensive analysis of flour quality in Table 1, the following flour tubes are selected as the raw materials for special cake flour: 1B1, 1B2, 1B3, 1B4, 3Bc1, 3Bc2, 3Bc3, 3Bc4, 4Bf1, 4Bf2, D21, D22, D3 , D4, 4M, 5M;

[0022] 4) Drying: Put the raw ma...

Embodiment 2

[0025] In the present embodiment, the preparation method of crispy tube special powder is as follows:

[0026] 1) Wheat blending: the wheat with a wet gluten content of 30.0%±0.5% and a stability time of 4.0 minutes is cleaned and removed by 3 sieves, 2 dozen and 2 stone removal processes;

[0027] 2) Moistening: Moisten the wheat cleaned in step 1), and the moisture content of the wheat is 15.0±0.3%;

[0028] 3) Grinding: Grinding, sifting, and clearing the wheat after step 2) moistening, and analyzing the physical and chemical indicators and the proportion of glutenin and gelatin content of each powder road flour, the results are shown in Table 1; according to For the comprehensive analysis of flour quality in Table 1, the following flour tubes were selected as the raw materials for special cake flour: 1B1, 1B2, 1B3, 1B4, 3Bc1, 3Bc2, 3Bc3, 3Bc4, 4Bf1, 4Bf2, D21, D22, D3, D4, 4M, 5M;

[0029] 4) Drying: Put the raw materials obtained in step 3) into the dryer to dry to beco...

Embodiment 3

[0032] In the present embodiment, the preparation method of crispy tube special powder is as follows:

[0033] 1) Wheat blending: the wheat with a wet gluten content of 30.0%±0.5% and a stabilization time of 5 minutes is cleaned and removed by 3 sieves, 2 dozen and 2 stone removal processes;

[0034] 2) Moistening: Moisten the wheat cleaned in step 1), and the moisture content of the wheat is 15.0±0.3%;

[0035] 3) Grinding: Grinding, sifting, and clearing the wheat after step 2) moistening, and analyzing the physical and chemical indicators and the proportion of glutenin and gelatin content of each powder road flour, the results are shown in Table 1; according to For the comprehensive analysis of flour quality in Table 1, the following flour tubes were selected as the raw materials for special cake flour: 1B1, 1B2, 1B3, 1B4, 3Bc1, 3Bc2, 3Bc3, 3Bc4, 4Bf1, 4Bf2, D21, D22, D3, D4, 4M, 5M;

[0036] 4) Drying: Put the raw materials obtained in step 3) into the dryer to dry to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com