A modified potassium titanate whisker/styrene-butadiene latex composite foaming material and its preparation process

A potassium titanate whisker and preparation technology, which is applied in shoe soles, clothing, footwear, etc., can solve the problems of general surface activity of modified styrene-butadiene latex and poor reactivity of cross-linking agents, etc., to overcome uneven stress transmission , promoting compatibility and optimizing process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

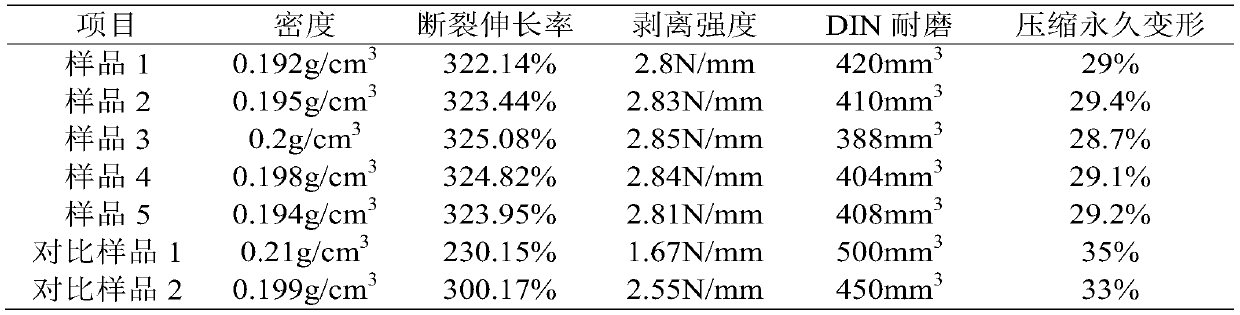

Examples

Embodiment 1

[0038] A preparation process for a modified potassium titanate whisker / styrene-butadiene latex composite foam material, comprising the following steps:

[0039] Step S1, add 200 parts by weight of potassium titanate whiskers to 1800 ml of deionized water, ultrasonically disperse for 20 minutes, then move the potassium titanate solution to a constant temperature water bath at 82°C, and stir to titanium at a stirring speed of 300r / min. 80 parts by weight of anionic polyacrylamide solution with a concentration of 0.2mol / L was added dropwise to the solution of potassium phosphate potassium, the pH value of the solution was adjusted to 9, and the temperature was kept for 2 hours. The obtained product was washed, filtered, and dried to obtain polyacrylamide-coated Potassium titanate whiskers;

[0040] Step S2, adding 100 parts by weight of coupling agent KH560 to a mixed solution of 3000ml deionized water and absolute ethanol (the volume ratio of deionized water and absolute ethanol...

Embodiment 2

[0047] A preparation process for a modified potassium titanate whisker / styrene-butadiene latex composite foam material, comprising the following steps:

[0048] Step S1, add 200 parts by weight of potassium titanate whiskers to 2400 ml of deionized water, ultrasonically disperse for 30 minutes, then move the potassium titanate solution to a constant temperature water bath at 88°C, and stir to titanium at a stirring speed of 400r / min. 100 parts by weight of an anionic polyacrylamide solution with a concentration of 0.2mol / L was added dropwise to the potassium acid potassium solution, and the pH value of the solution was adjusted to 10. Potassium titanate whiskers;

[0049] Step S2, adding 120 parts by weight of coupling agent KH560 to a mixed solution of 4200ml deionized water and absolute ethanol (the volume ratio of deionized water and absolute ethanol is: 1:16) to form a coupling agent solution, and then Add dropwise glacial acetic acid to the coupling agent solution to adj...

Embodiment 3

[0056] A preparation process for a modified potassium titanate whisker / styrene-butadiene latex composite foam material, comprising the following steps:

[0057] Step S1, add 200 parts by weight of potassium titanate whiskers to 2100 ml of deionized water, ultrasonically disperse for 25 minutes, then move the potassium titanate solution to a constant temperature water bath at 85°C, and stir to titanium at a stirring speed of 350r / min. 90 parts by weight of an anionic polyacrylamide solution with a concentration of 0.2mol / L was added dropwise to the potassium acid potassium solution, and the pH value of the solution was adjusted to 9.5. Potassium titanate whiskers;

[0058] Step S2, adding 110 parts by weight of coupling agent KH560 to a mixed solution of 3600ml deionized water and absolute ethanol (the volume ratio of deionized water and absolute ethanol is: 1:15) to form a coupling agent solution, and then Add glacial acetic acid dropwise to the coupling agent solution to adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com