A kind of negative water-based paint emulsion and its production process

A water-based coating and production process technology, applied in anti-corrosion coatings, electrophoretic coatings, epoxy resin coatings, etc., can solve the problems of uneven distribution of electrophoretic coating film thickness, easy occurrence of small particles in the dispersion process, and waste of production raw materials. To achieve the effect of increasing anti-corrosion effect, improving anti-corrosion effect and good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

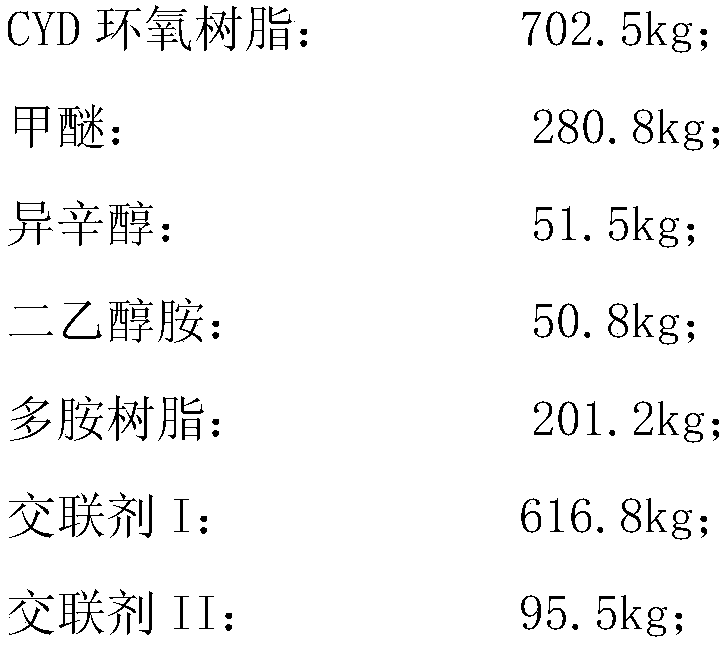

[0051] A negative water-based paint emulsion is made from the following raw materials:

[0052]

[0053]

[0054] The production process includes the following steps:

[0055] Step 1: Add the prescribed amount of epoxy resin, methyl ether and isooctyl alcohol into the epoxy kettle for melting epoxy resin, heat up to 60°C, start stirring, and continue to heat up until the epoxy resin in the kettle is completely melted At this time, the temperature is about 110°C. Open the lid of the epoxy kettle to confirm that the epoxy resin is completely melted.

[0056] Step 2: Put all the melted epoxy resin into the reaction kettle, raise the temperature to 80°C, add the formula amount of diethanolamine, and keep it warm for 2 hours at this temperature.

[0057] Step 3: After the heat preservation is completed, add the formulated amount of polyamine resin, then raise the temperature to 100° C., and heat the reaction for 2 hours.

[0058] Step 4: After the heat preservation reaction...

Embodiment 2

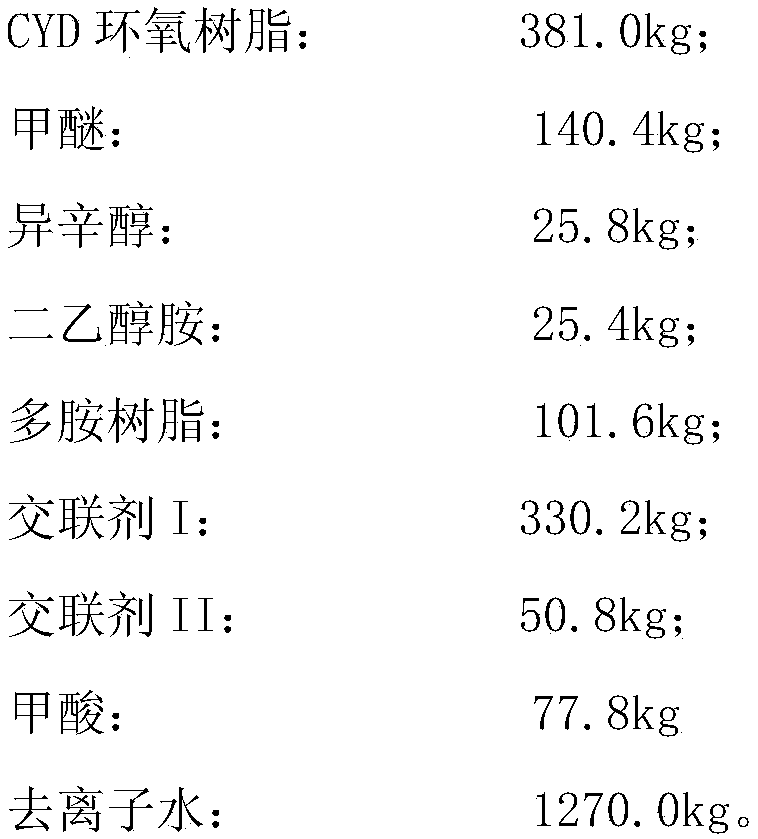

[0062] A negative water-based paint emulsion is made from the following raw materials:

[0063]

[0064] The production process includes the following steps:

[0065] Step 1: Add the prescribed amount of epoxy resin, methyl ether and isooctyl alcohol into the epoxy kettle used to melt the epoxy resin, heat up to 65°C, start stirring, and continue to heat up until the epoxy resin in the kettle is completely melted At this time, the temperature is about 110°C. Open the lid of the epoxy kettle to confirm that the epoxy resin is completely melted.

[0066] Step 2: Put all the melted epoxy resin into the reaction kettle, raise the temperature to 85°C, add the formula amount of diethanolamine, and keep it warm for 2.5 hours at this temperature.

[0067] Step 3: After the heat preservation is completed, add the formulated amount of polyamine resin, then raise the temperature to 101° C., and heat the reaction for 2.2 hours.

[0068] Step 4: After the heat preservation reaction is...

Embodiment 3

[0072] A negative water-based paint emulsion is made from the following raw materials:

[0073]

[0074] The production process includes the following steps:

[0075] Step 1: Add the prescribed amount of epoxy resin, methyl ether and isooctyl alcohol into the epoxy kettle used to melt the epoxy resin, heat up to 70°C, start stirring, and continue to heat up until the epoxy resin in the kettle is completely melted At this time, the temperature is about 110°C. Open the lid of the epoxy kettle to confirm that the epoxy resin is completely melted.

[0076] Step 2: put all the melted epoxy resin into the reaction kettle, raise the temperature to 83°C, add the formula amount of diethanolamine, and keep it warm for 2.2 hours at this temperature.

[0077] Step 3: After the heat preservation is completed, add the formulated amount of polyamine resin, then raise the temperature to 99° C., and heat the reaction for 2.5 hours.

[0078] Step 4: After the heat preservation reaction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com