Damping type crushing, screening and iron removing device for battery materials

A lithium battery material and screening device technology, applied in springs/shock absorbers, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems that affect the service life of the crushing effect device, the ferromagnetic slag is easy to cause blockage, and it is inconvenient to clean. , to achieve the effect of strong practicability, convenient cleaning and lightening labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

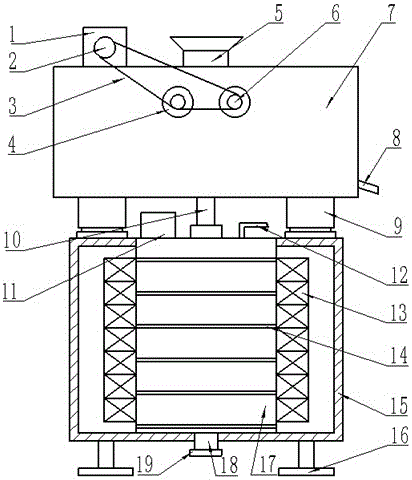

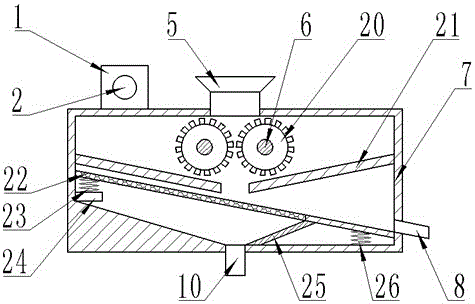

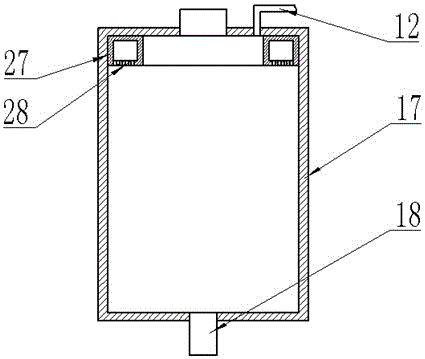

[0020] see Figure 1-4 , A shock absorption type lithium battery material crushing, screening and iron removal device, including a shock absorption crushing screening device and an iron removal and discharging device; Drum 5, rotating shaft 6, crushing box 7, discharge pipe 8, shock absorber 9, discharge pipe 10, crushing wheel 20, material guide plate 21, screen plate 22, first spring 23, fixing plate 24, The connecting plate 25 and the second spring 26; the shock absorbing device 9 is provided with two, welded on both sides above the protection sleeve 15, including a fixing box 29, a supporting box 30, a rubber fixing sleeve 31, a first fixing column 32, The shock-absorbing spring 33 and the second fixing column 34; the fixing box 29 is welded on the lower end surface of the crushing box 7; the second fixing column 34 is provided with two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com