M50-Ag-TiC self-lubricating composite material and preparation method thereof

A composite material and self-lubricating technology, applied in additive manufacturing, additive processing, metal processing equipment, etc., can solve problems such as uneven temperature distribution, small size of sintered body, uncomplicated shape, etc., to improve mechanical properties and friction and wear Excellent performance, uniform temperature distribution and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

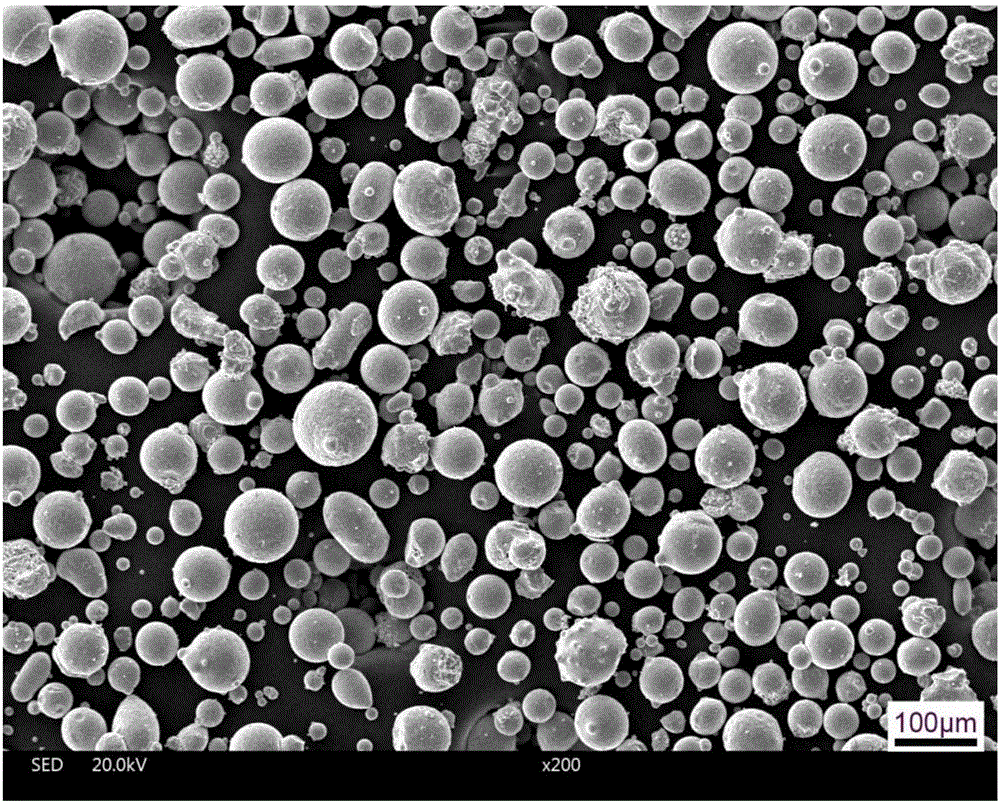

[0033] In the following examples, the M50-Ag-TiC self-lubricating composite material is prepared from M50 spherical powder containing Ag and TiC. The present invention provides a specific preparation method, but does not limit its preparation method. M50 spherical powder containing Ag and TiC and M50-Ag-TiC self-lubricating composite materials prepared by other methods that meet the requirements of the present invention also belong to the present invention protected range.

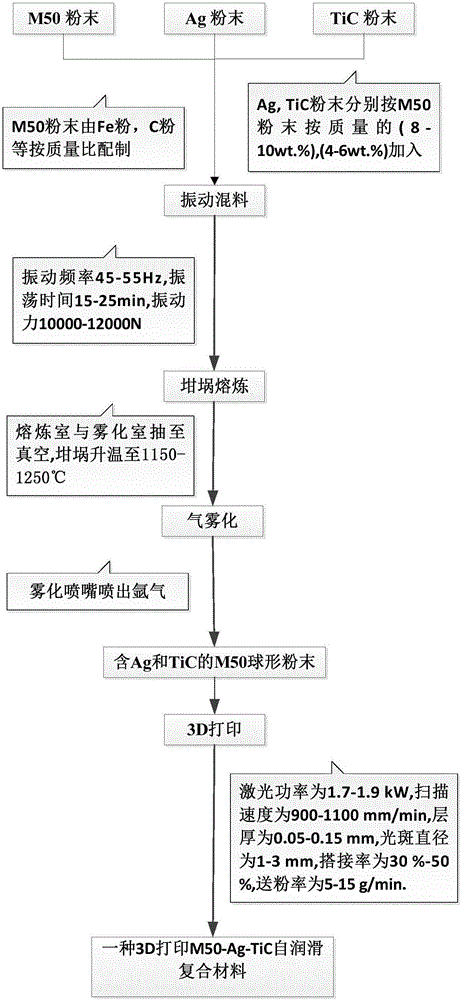

[0034] The invention provides a preparation method of M50-Ag-TiC self-lubricating composite material, comprising the following steps:

[0035] 1) According to the constituent elements and content of M50 steel, weigh the elemental powder of its constituent elements as the raw material of the matrix material; and weigh the lubricating phase Ag powder according to the (8.0-10.0) wt.% of the raw material quality of the matrix material , according to (4.0-6.0)wt.% of the raw material quality of the matrix mate...

Embodiment 1

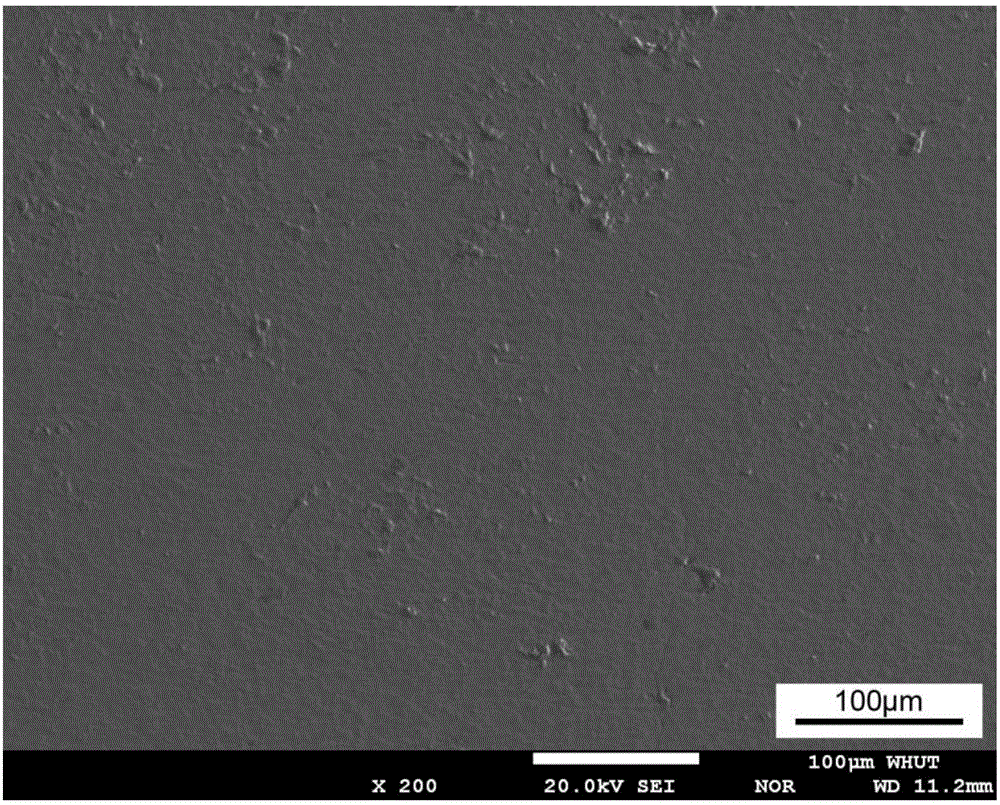

[0039] A M50-Ag-TiC self-lubricating composite material, including a matrix material, a lubricating phase, and a reinforcing phase, which uses M50 steel as the matrix material, Ag as the lubricating phase, and TiC as the reinforcing phase; the added lubricating phase Ag and reinforcing phase The mass of the phase TiC powder is 8.0wt.% and 4.0wt.% of the mass of the matrix material M50, respectively. The matrix material M50 steel includes elements C, Mn, Si, Ni, Cr, Cu, Mo, V and Fe, elements C, Mn , Si, Ni, Cr, Cu, Mo, V and Fe mass ratio is 0.75:0.35:0.30:0.20:4.0:0.15:4.2:1:89.05.

[0040] like figure 1 As shown, the preparation method of the above-mentioned M50-Ag-TiC self-lubricating composite material is to use the above-mentioned M50 spherical powder containing Ag and TiC to obtain the M50-Ag-TiC self-lubricating composite material through 3D printing (that is, laser fusion deposition). Specific steps are as follows:

[0041] 1) The raw materials of the matrix material...

Embodiment 2

[0049] A M50-Ag-TiC self-lubricating composite material, including a matrix material, a lubricating phase, and a reinforcing phase, which uses M50 steel as the matrix material, Ag as the lubricating phase, and TiC as the reinforcing phase; the added lubricating phase Ag and reinforcing phase The mass of phase TiC powder is respectively 9.0wt.% and 5.0wt.% of the mass of the matrix material M50, the matrix material M50 steel includes elements C, Mn, Si, Ni, Cr, Cu, Mo, V and Fe, elements C, Mn , Si, Ni, Cr, Cu, Mo, V and Fe mass ratio is 0.75:0.35:0.30:0.20:4.0:0.15:4.2:1:89.05.

[0050] like figure 1 As shown, the preparation method of the above-mentioned M50-Ag-TiC self-lubricating composite material is to use the above-mentioned M50 spherical powder containing Ag and TiC to obtain the M50-Ag-TiC self-lubricating composite material through 3D printing (that is, laser fusion deposition). Specific steps are as follows:

[0051] 1) The raw materials of the matrix material M50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com