Rock sample polishing method and device

A technology of rock samples and polishing devices, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, surface polishing machine tools, etc., and can solve the problems of small particle-particle binding force, influence of experimental phenomena and experimental results, and particle shedding And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

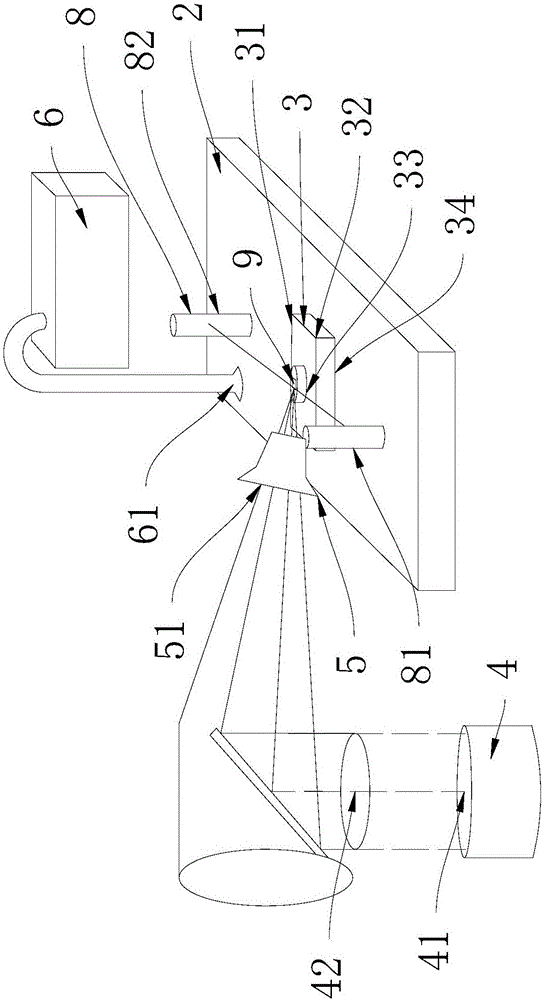

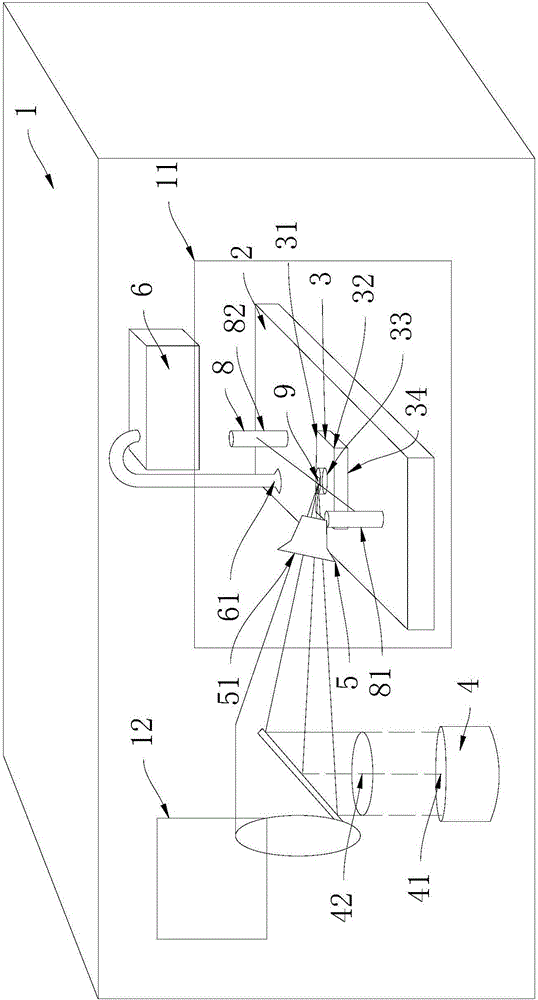

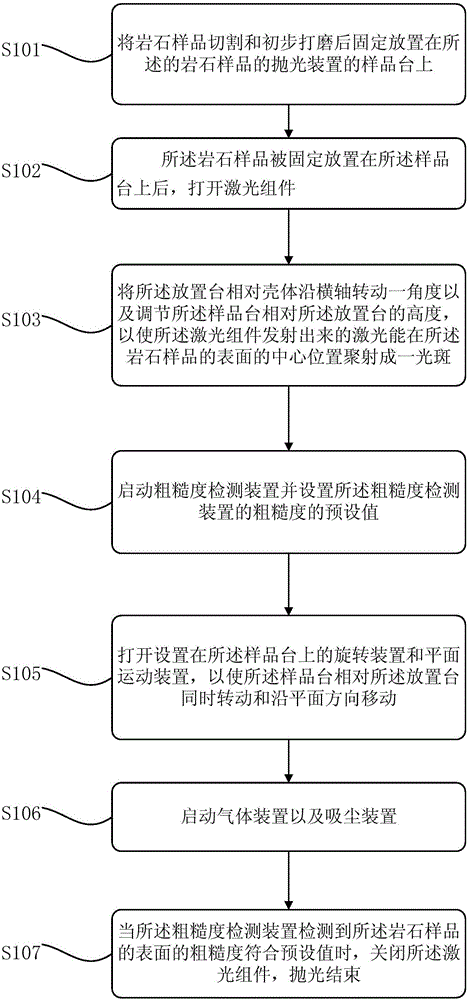

[0124] Shale rock samples were taken from a survey site in Sichuan9. Such samples are prone to micro-cracks when exposed to water, so they cannot be polished by the method of polishing with water in the prior art. The rock sample 9 has an initial diameter of 2.5 cm and a thickness of 1 cm. Use sandpaper to roughly grind the upper and lower surfaces of the rock slices, and the upper and lower surfaces are approximately parallel, as samples to be polished. Fix the rock sample 9 on the scanning electron microscope nail-shaped sample stage 3 with AB glue, keep the surface of the sample stage 3 parallel to the upper surface of the rock sample 9 as much as possible, and fix the nail-shaped sample stage 3 on the belt rotation device 33 and the planar movement device 34 The sample stage 3. Set the moving range of the plane in the X direction to 10 mm, and the moving speed to 2 mm / s; set the rotating speed of the rotating device to 5 r / min; set the inclination angle of the tiltable s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com