Production line for pouring epoxy resin into automobile ignition coil

An automotive ignition coil, epoxy resin technology, applied in packaging/impregnation, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of not being able to fill the automotive ignition coil, and the processing quality will decrease, and achieve a small footprint. , easy to flow, improve the effect of perfusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

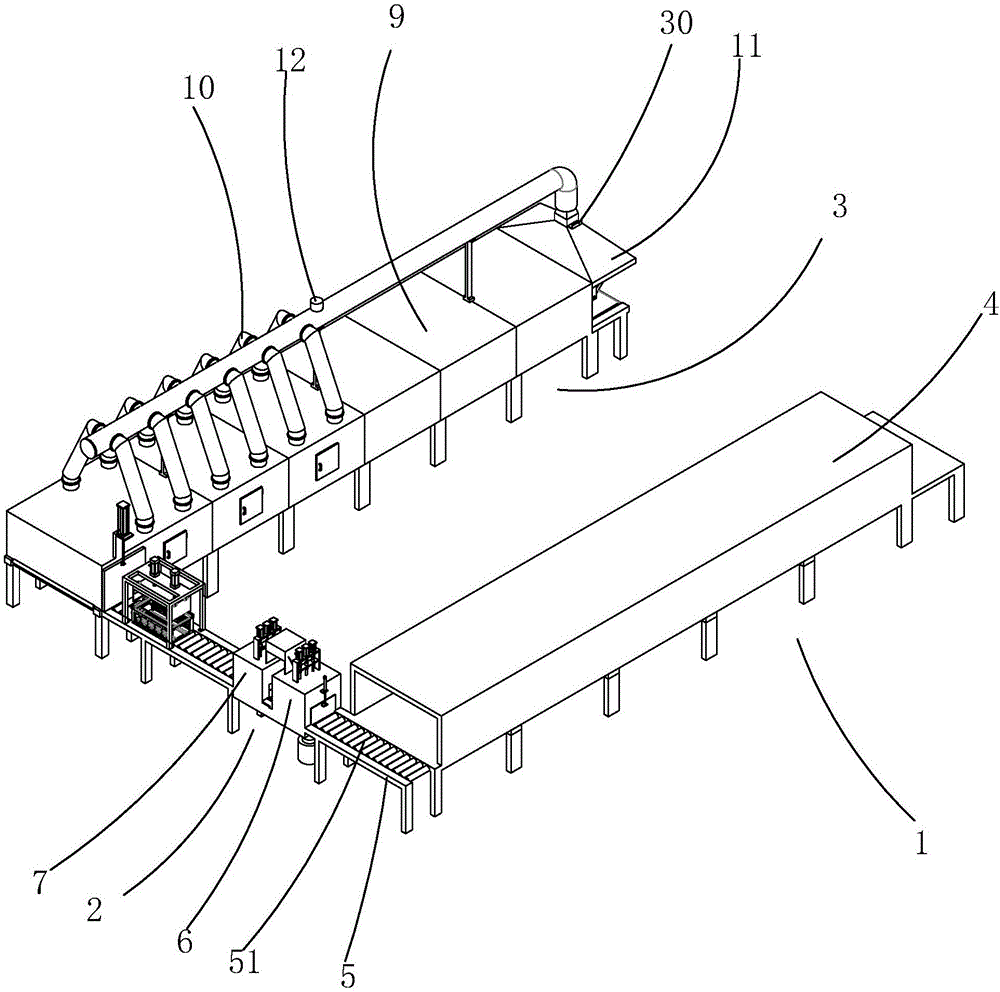

[0039] Such as figure 1 As shown, a production line for epoxy resin filling of automobile ignition coils includes a preheating device 1, a filling device 2 and a drying device 3. During the filling process, automobile ignition coils are arranged and placed in a placement frame.

[0040]The preheating device 1 includes a preheating oven 4, an electric heating device is arranged in the preheating oven 4, and the placing frame enters the preheating device 1 for heating, so that the automobile ignition coil maintains a higher temperature. The epoxy resin in contact with the automobile ignition coil can maintain a certain temperature and facilitate circulation, thereby improving the filling effect.

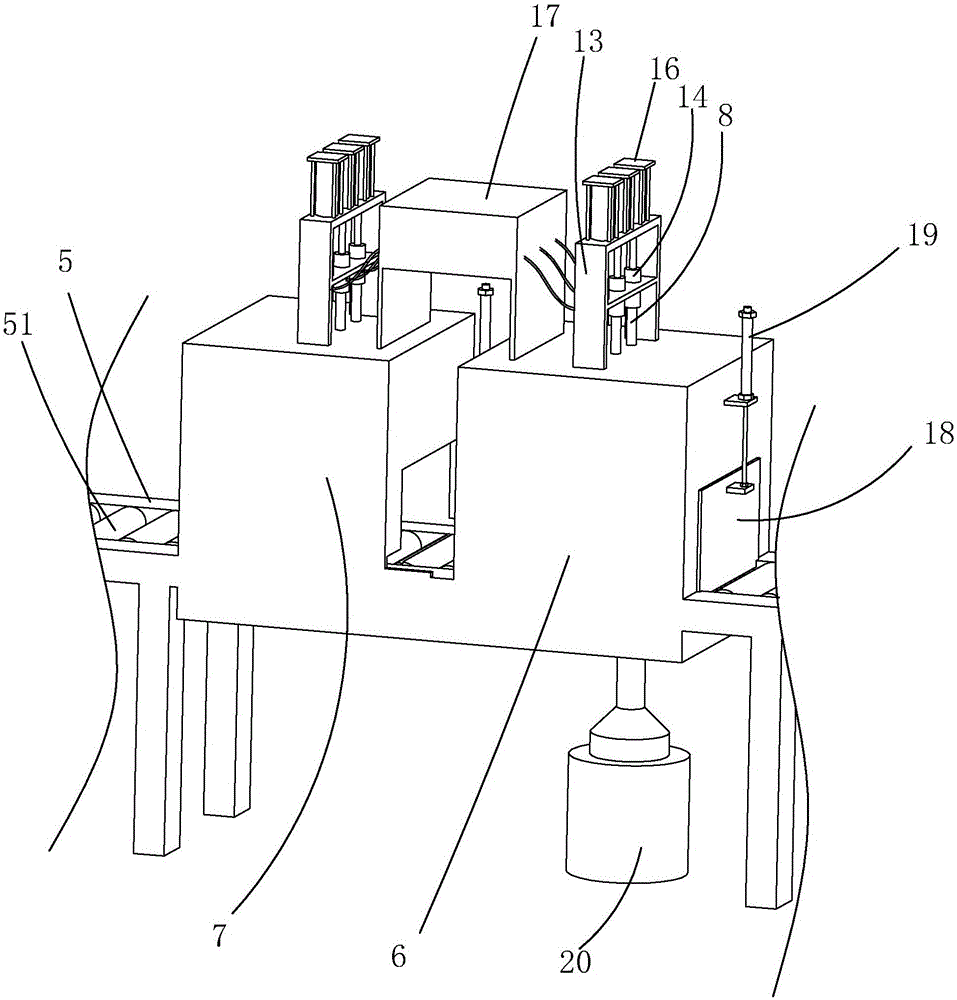

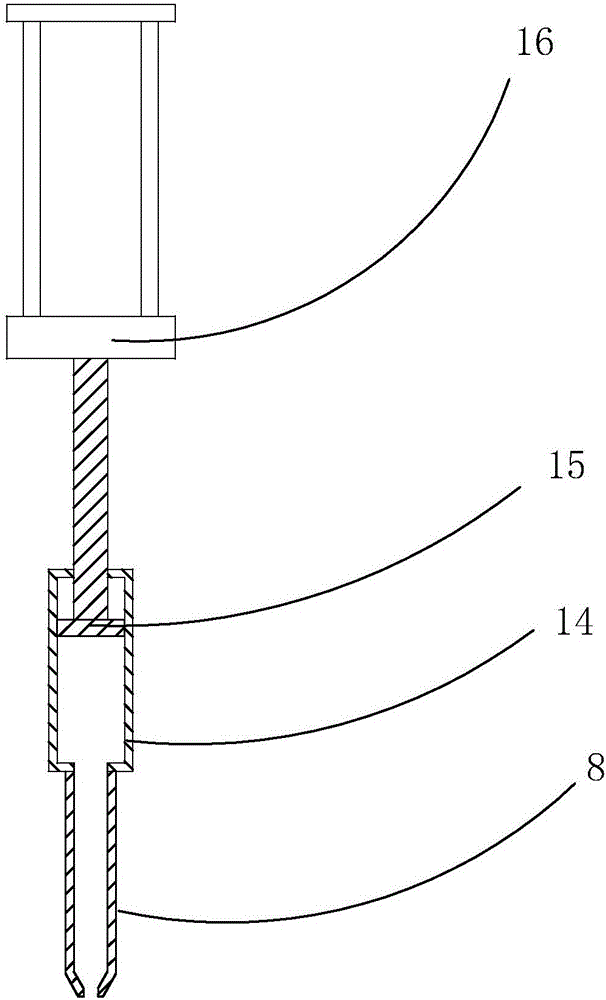

[0041] Such as figure 1 , figure 2 and image 3 As shown, after the preheating is completed, the placing frame is transferred to the conveying frame 5 in the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com