Wheel-type hydrostatic driving intelligent universal chassis of grain harvesting machine

A hydrostatic drive, harvester technology, applied in the field of agricultural machinery, can solve the problems of small ground clearance, large turning radius, low intelligence, etc., and achieve the effects of reducing production costs, eliminating drift and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

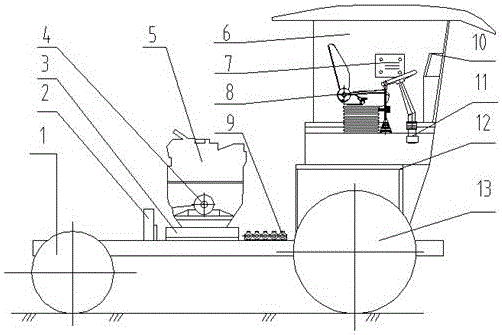

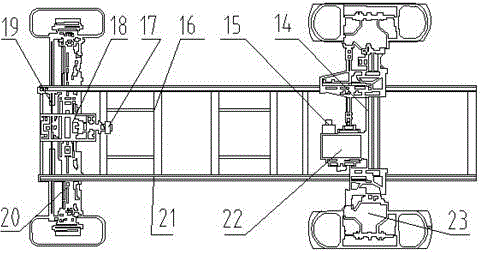

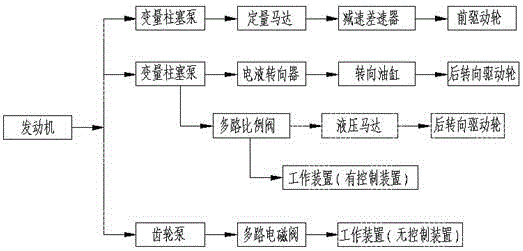

[0028] refer to figure 1 , figure 2 , the overall structure of the present invention is: front and rear axles 14, 20 are installed on the frame type frame 21, front drive wheels 13 are installed at both ends of the front axle 14, and a secondary speed differential (high and low speed) 22 is connected in the middle , the power can be transmitted to the left and right wheel side reducers 23, and then drive the front drive wheels 13, the power of the transmission is driven by the hydraulic motor 15; the rear axle 20 is equipped with a differential gearbox 18 driven by the hydraulic motor 17 in the middle The power is transmitted to the rear drive steering wheel 1, while the rear axle 20 is equipped with a steering oil cylinder 19 to turn the left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com