Solute and liquid mixing container and production method

A technology for mixing containers and liquid containers, which is applied to containers with multiple items, containers, transportation and packaging, etc., can solve the problems of easy loosening and falling, high manufacturing cost, easy loosening, etc., and achieve the effect of eliminating peroxygen free.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

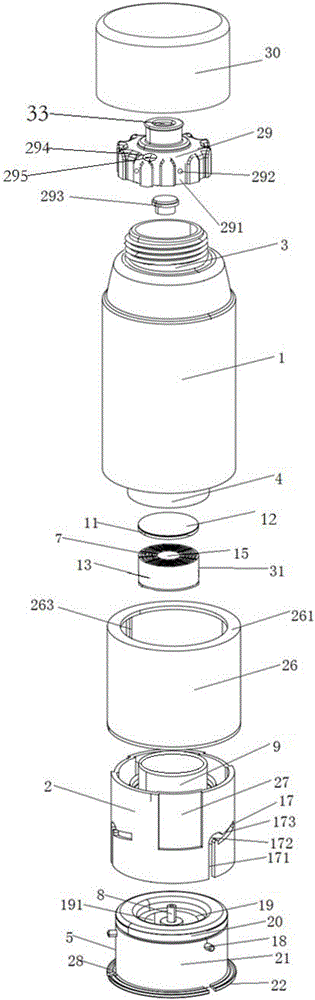

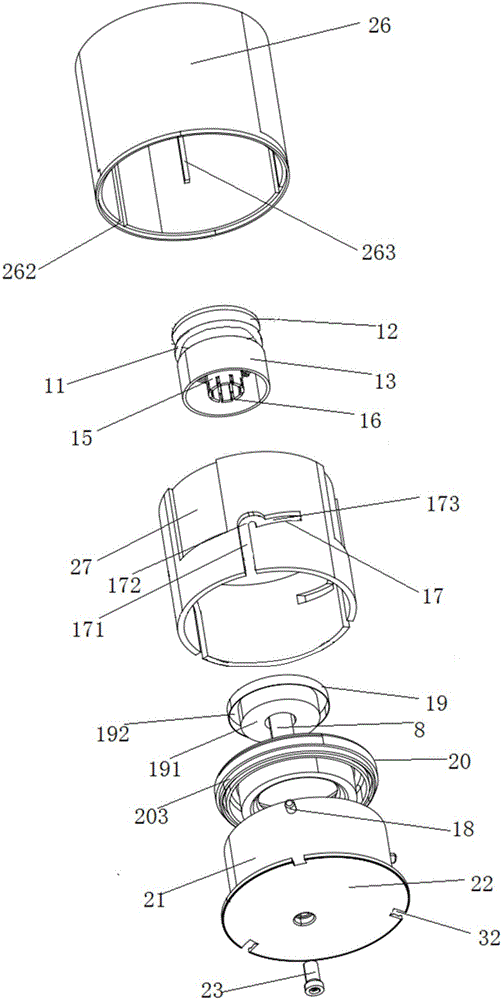

[0036] Such as figure 1 and figure 2 As shown, a mixing container of solute and liquid described in this embodiment includes a liquid container 1 and a connecting piece 2, the liquid container 1 is provided with a liquid outlet 3 and a mixing port 4, and the liquid outlet 3 is detachably connected with The bottle cap assembly, the communication part 2 is a tubular structure including an upper opening and a lower opening, and the mixing port 4 is in airtight communication with the upper opening of the communication part 2. The first solute or the second solute in the container 1 needs to be refined by the solute refinement component so that it can be dissolved in the liquid in the liquid container 1 more quickly. There is a top chamber with an upper opening and a partition 14 with a bottom chamber with a lower opening. The partition is provided with a first one-way valve 6, and the top chamber is provided with a solute cover 31 that is movably sleeved outside the first one-wa...

Embodiment 2

[0052] Such as Figure 8 As shown, this embodiment is the same as that of Embodiment 1, except that the locking assembly includes a locking edge 34 provided on the outer wall of the mouth of the bottle mouth 33 and a matching lock seat provided in the bottle cap 30, the lock seat It is a cavity-shaped structure surrounded by four inwardly protruding arc-shaped lock bars 304 fixed in the bottle cap 30 .

Embodiment 3

[0054] Such as Figure 9 As shown, this embodiment is the same as that of Embodiment 1, except that the air intake assembly includes an air intake hole 294 provided on the bottle mouth 29 and an annular sheet 296 sleeved outside the liquid outlet cross valve 293, the sheet 296 covers the air intake hole 294 bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com