Method for operating sewage treatment fluidized bed

A technology of sewage treatment and operation method, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high operating energy consumption of sewage treatment technology, and reduce the energy consumption of aeration , The effect of reducing the loss of bed material particles and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

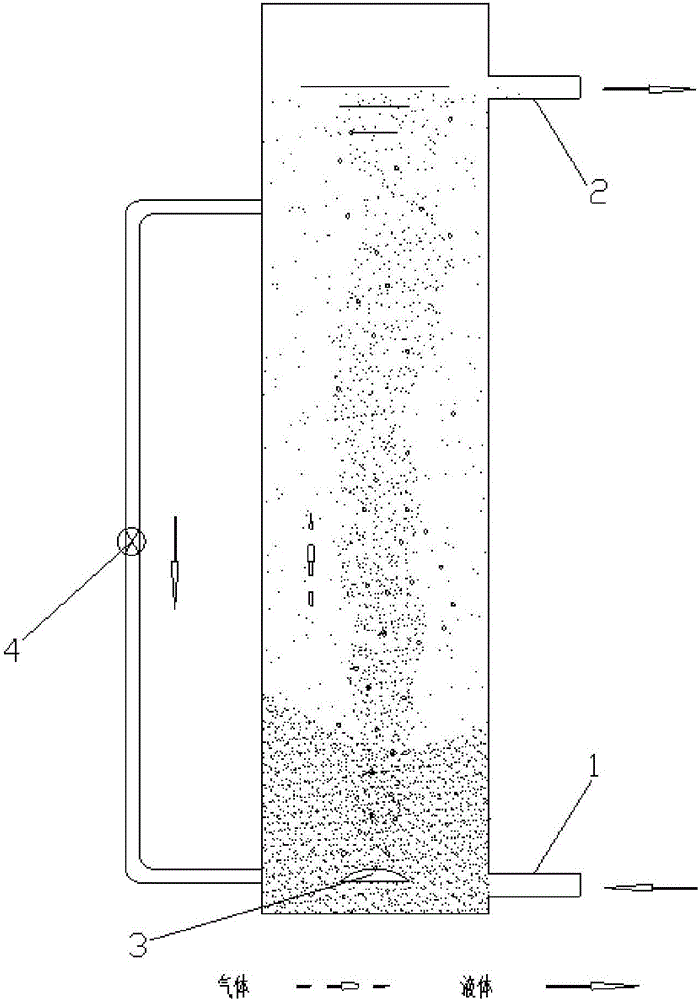

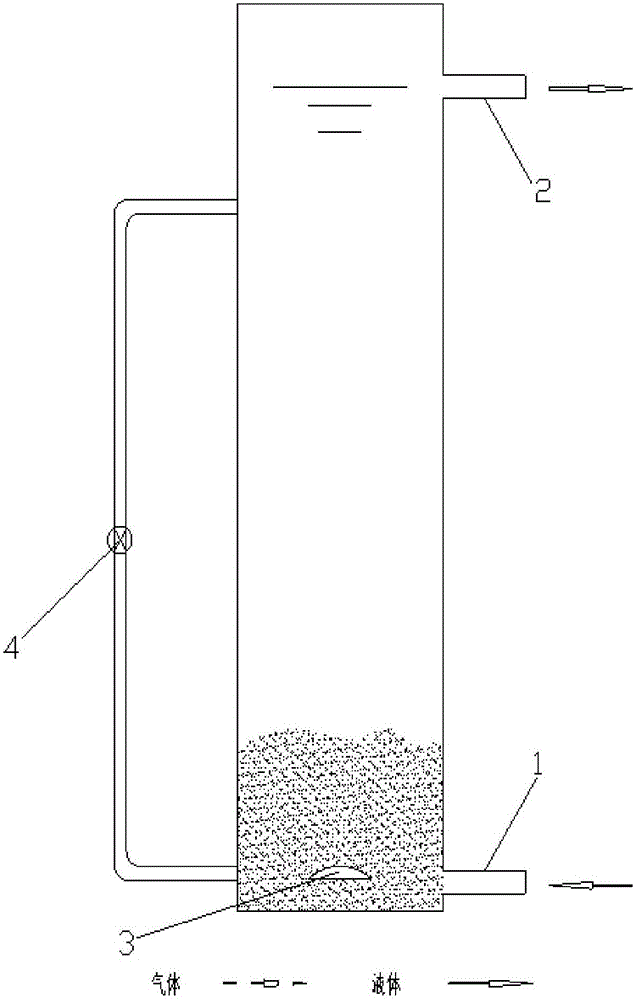

[0034] Such as Figure 1~3 As shown, a low-energy operation method for a fluidized bed for sewage treatment, which is provided with an aeration cycle and a circulating water cycle, by periodically and alternately feeding circulating water and gas to the bottom of the fluidized bed to make the fluidized bed The bed material particles loaded with biofilm are in a fluidized state.

[0035] Such as figure 1 As shown, the operation of the aeration cycle in this embodiment is as follows: during the aeration cycle, stop feeding circulating water to the bottom of the fluidized bed, only feed gas to the bottom of the fluidized bed, and only use the gas and the water flow driven by the gas to make the The bed material particles maintain a fluidized state. During this cycle, the bed material particles in the fluidized bed are fluidized under the action of air bubbles formed by aeration and the water flow driven by the bubbles, and a large number of bed material particles are entrained ...

Embodiment 2

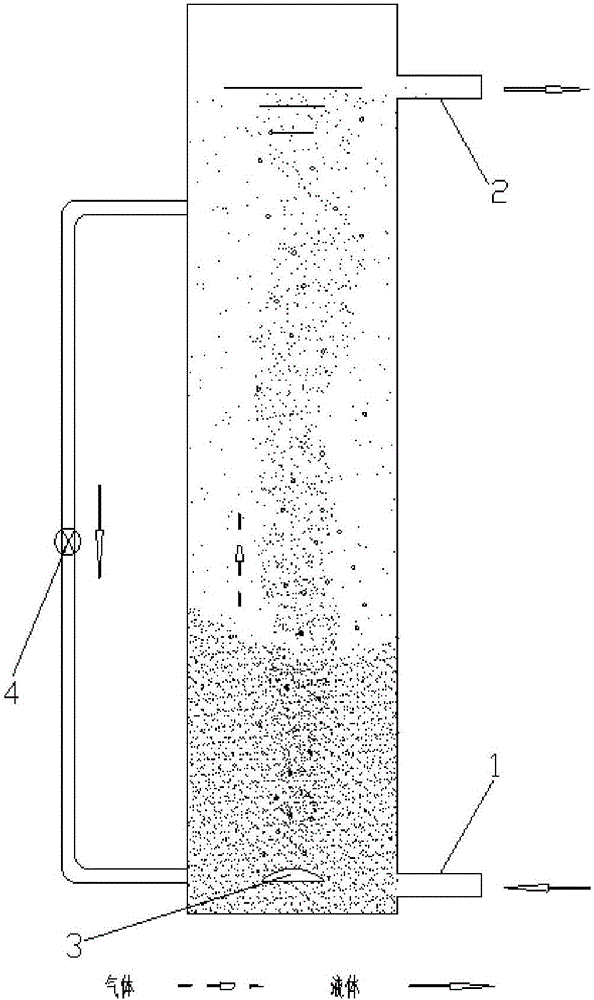

[0046] A low-energy operation method for a fluidized bed for sewage treatment, which is provided with an aeration cycle and a circulating water cycle, and periodically and alternately feeds circulating water and gas to the bottom of the fluidized bed so that the fluidized bed is loaded with biological The bed material particles of the membrane are in a fluidized state.

[0047] Such as Figure 4 Shown is the operation of the aeration cycle of this embodiment: in the aeration cycle, circulating water and gas are introduced to the bottom of the fluidized bed at the same time, and the bed material particles in the fluidized bed are driven by the air bubbles and air bubbles formed by aeration. Fluidization is achieved under the joint action of the water flow and circulating water. During this cycle, the bed material particles in the fluidized bed are fluidized under the joint action of air bubbles formed by aeration, water flow driven by the bubbles, and circulating water, and a ...

Embodiment 3

[0060] Referring to Example 2, the difference between Example 3 and Example 2 is that the ratio of the duration of the aeration cycle to the water circulation cycle is 70:30. As shown in the table below, it is the index comparison table 3 between the water quality obtained by the operation of the fluidized bed in the manner of embodiment 3 and the water quality obtained by the operation of the fluidized bed in the manner of continuous water intake and air intake. There is no significant difference between the water quality obtained by the method 3 and the water quality obtained by the continuous water intake method, and both meet the sewage treatment standards, that is, the water quality treated by the method 3 of this embodiment meets the sewage treatment requirements. Through the operation mode of Embodiment 3 of the present invention, the operating energy consumption of the fluidized bed can be reduced to about 1 / 2 of the operating energy consumption of the fluidized bed und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com