Multi-unit modified sequencing batch reactor and application thereof

An improved reactor technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems such as unresolved operating parameters, difficult operation, and difficulty in meeting sewage water quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

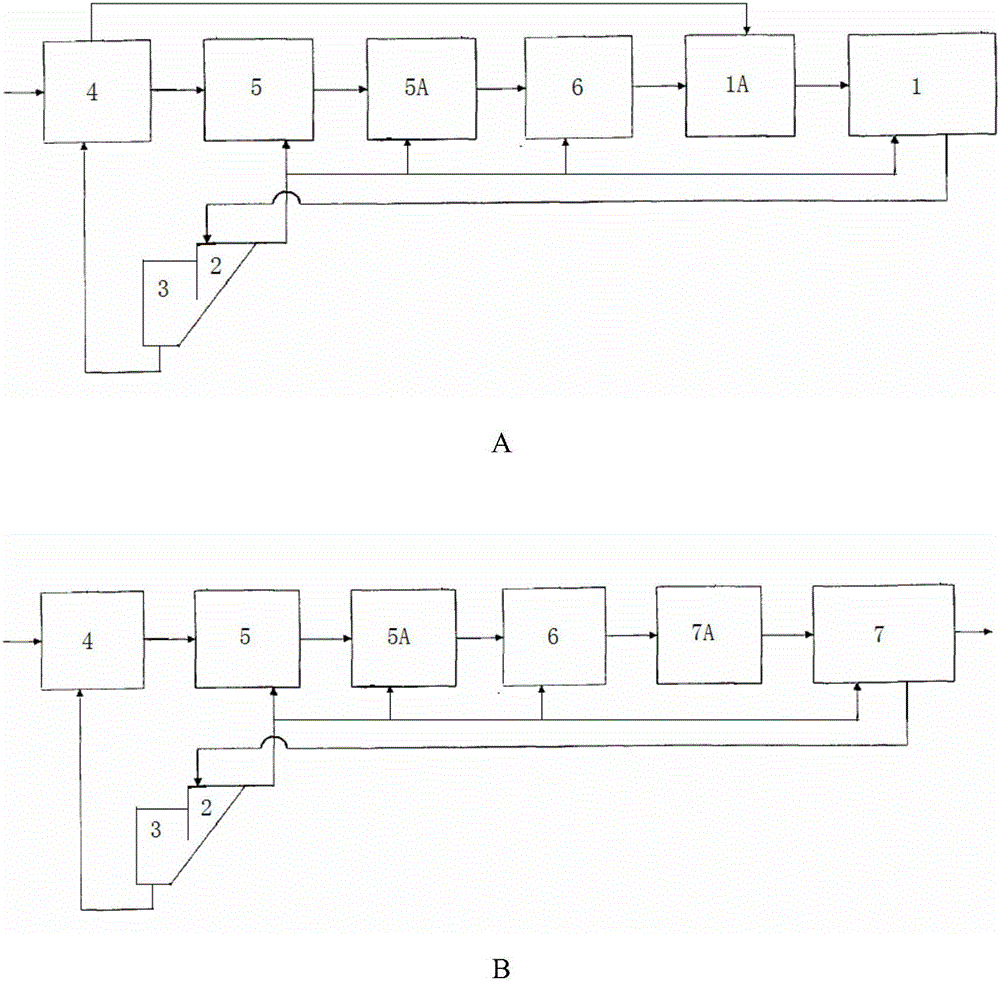

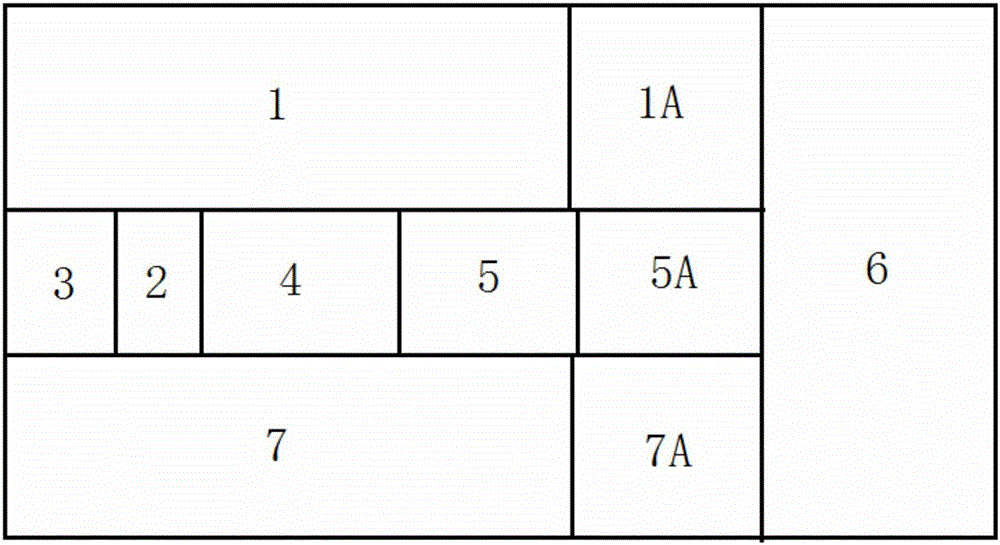

[0043] The first aspect of the present invention provides an improved sequence batch batch reactor, which includes anaerobic reaction unit, the first anoxic reaction unit, mud-water separation unit, aerobic unit, the first sequence batch unit, the second sequence batch unit, Pre-anoxic unit, second anoxic response unit, first anoxic / aerobic response unit and second anoxic / aerobic response unit.

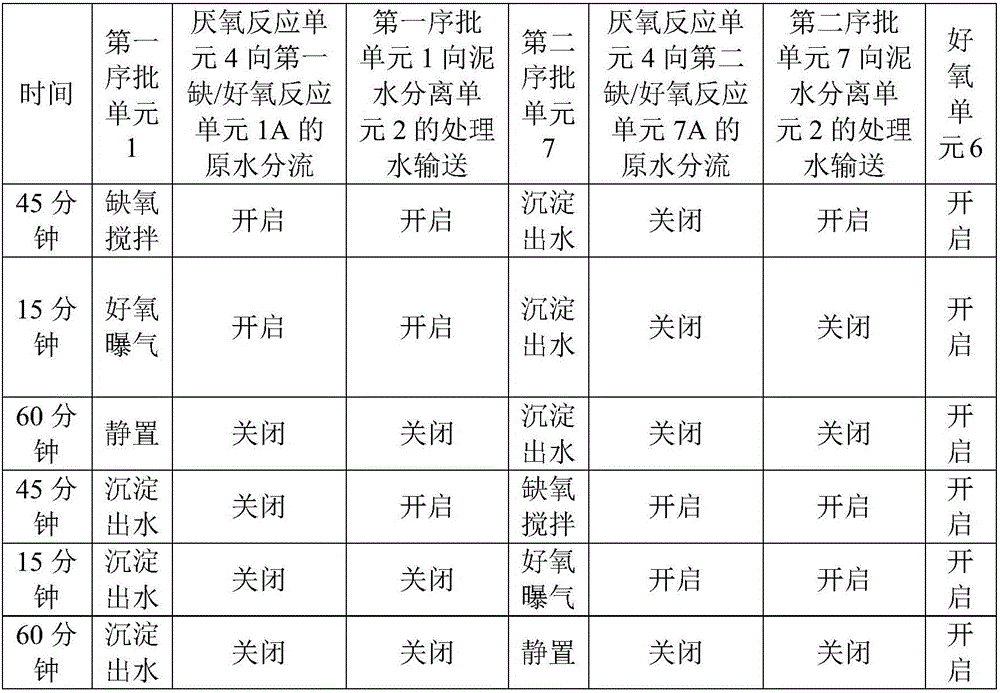

[0044] Herein, the modified sequencing batch reactor is also referred to as the modified sequencing batch reactor, which comprises at least two sequencing batch units. In the first half of a typical operating cycle, the raw water flows through the anaerobic reaction unit, the first anoxic reaction unit, the aerobic unit, the first anoxic / aerobic reaction unit and the first sequencing batch unit, and then flows into the sludge-water separation unit The unit is separated into supernatant and sediment, wherein the sediment is transported to the anaerobic reaction unit through the pre-anoxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com