Polyurethane rigid foam material for water storage electric water heater and preparation method thereof

A polyurethane rigid foam and electric water heater technology, applied in the field of polyurethane, can solve the problems of high thermal conductivity of cyclopentane and water, reduced water storage capacity of water tank, and failure to meet ODP requirements, etc., to achieve good airtightness, increased water storage capacity, and low odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of component A:

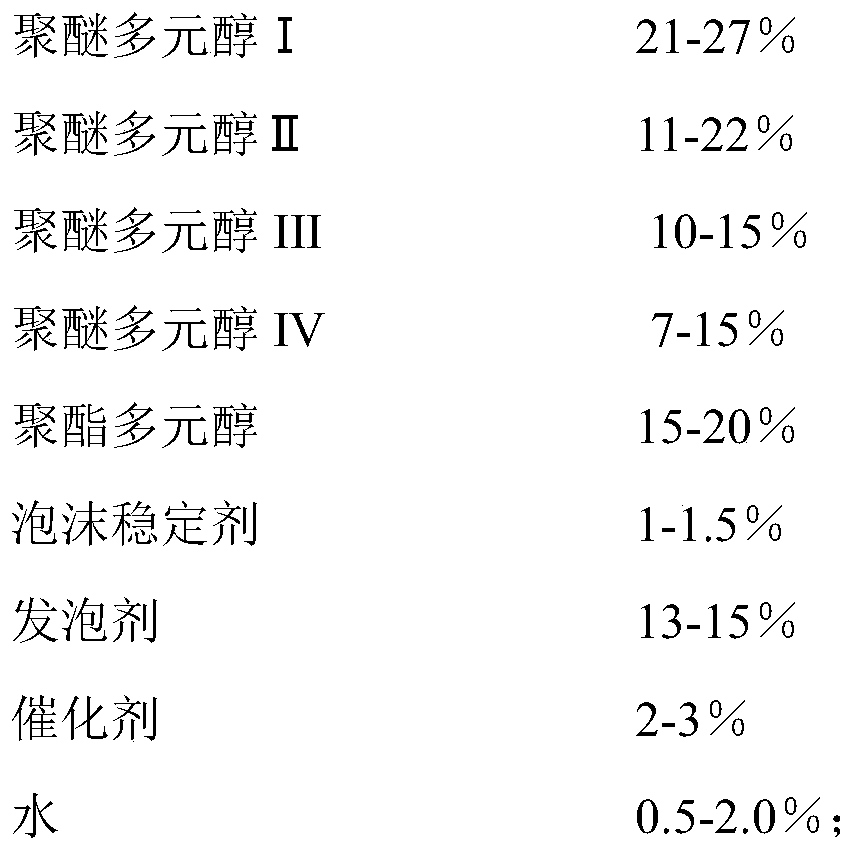

[0033] The raw material composition of component A is shown in Table 1.

[0034] A component raw material composition in the embodiment 1 of table 1

[0035]

[0036]

[0037] Add the above-mentioned raw materials (except foaming agent) weighed into the reaction kettle, stir at room temperature for 0.5h, mix thoroughly, then add foaming agent, and mix thoroughly for 1h, and weigh 100kg after mixing. The foaming agent is a mixed foaming agent of cyclopentane, isopentane, and HFC-245fa at a ratio of 50:15:35.

[0038] (2) Preparation of component B: Weigh 120 kg of Yantai Wanhua PM200.

[0039] (3) The components A and B are uniformly mixed and foamed by a high-pressure machine according to the mass ratio of 1:1.2, and injected into a 300mm×300mm×100mm mold, and the molded foam density is 38.6kg / m 3 , the polyurethane rigid foam material was obtained, and the product quality index obtained is shown in Table 4.

Embodiment 2

[0041] (1) Preparation of component A:

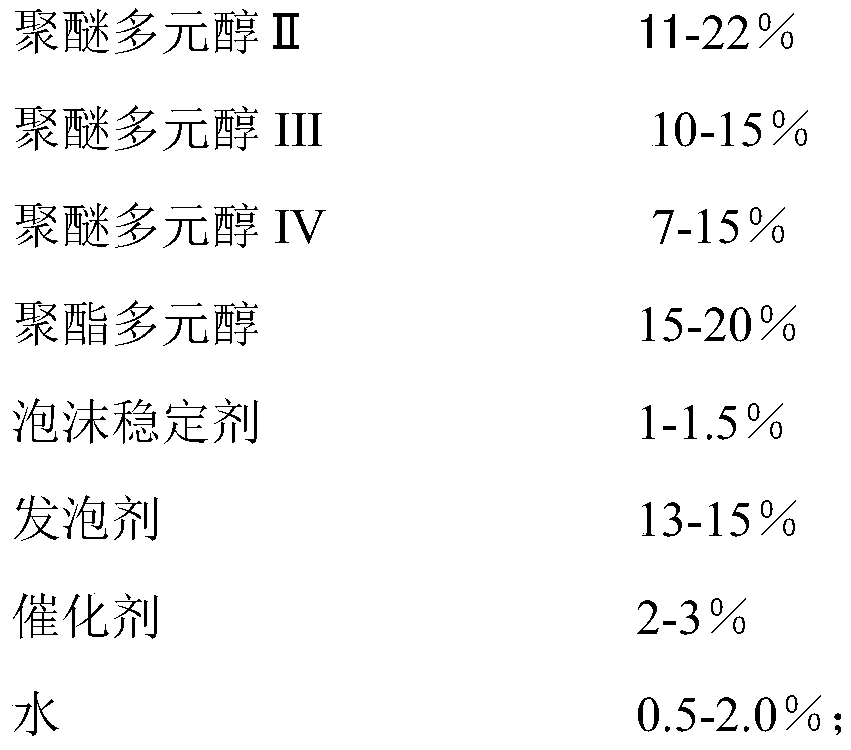

[0042] The raw material composition of component A is shown in Table 2.

[0043] A component raw material composition in the embodiment 2 of table 2

[0044]

[0045] Add the above-mentioned raw materials (except foaming agent) weighed into the reaction kettle, stir at room temperature for 0.5 hours, mix thoroughly, then add foaming agent, and mix thoroughly for 1 hour. Weigh 100kg after mixing. The foaming agent is a mixed foaming agent of cyclopentane, isopentane, and HFC-245fa at a ratio of 50:15:35.

[0046] (2) Preparation of component B: Weigh 120 kg of 44V20 from Bayer, Germany.

[0047] (3) The components A and B are uniformly mixed and foamed by a high-pressure machine according to the mass ratio of 1:1.2, and injected into a 300mm×300mm×100mm mold, and the molded foam density is controlled at 36.6kg / m 3 , the polyurethane rigid foam material was obtained, and the product quality index obtained is shown in Table 4.

Embodiment 3

[0049] (1) Preparation of component A:

[0050] The raw material composition of component A is shown in Table 3.

[0051] A component raw material composition in the embodiment 3 of table 3

[0052]

[0053] Add the above-mentioned raw materials (except foaming agent) weighed into the reaction kettle, stir at room temperature for 0.5 hours, mix thoroughly, then add foaming agent, and mix thoroughly for 1 hour. Weigh 100kg after mixing. The foaming agent is a mixed foaming agent of cyclopentane, isopentane, and HFC-245fa at a ratio of 50:15:35.

[0054] (2) Preparation of component B: Weigh 120 kg of Yantai Wanhua PM200.

[0055](3) The components A and B are uniformly mixed and foamed by a high-pressure machine according to the mass ratio of 1:1.2, and injected into a 300mm×300mm×100mm mold, and the molded foam density is controlled at 35.4kg / m 3 , the polyurethane rigid foam material was obtained, and the product quality index obtained is shown in Table 4.

[0056] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com