Heat treatment process method for processing CAH (Calcium Alginate Hydrogel) artificial muscles

A technology of artificial muscle and process method, which is applied in the field of heat treatment process for processing CAH artificial muscle, can solve the problems that have not yet appeared, ignore the processing, improve the actuation performance, etc., achieve the elimination of residual internal stress, reduce the use of deformation and the risk of cracks, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

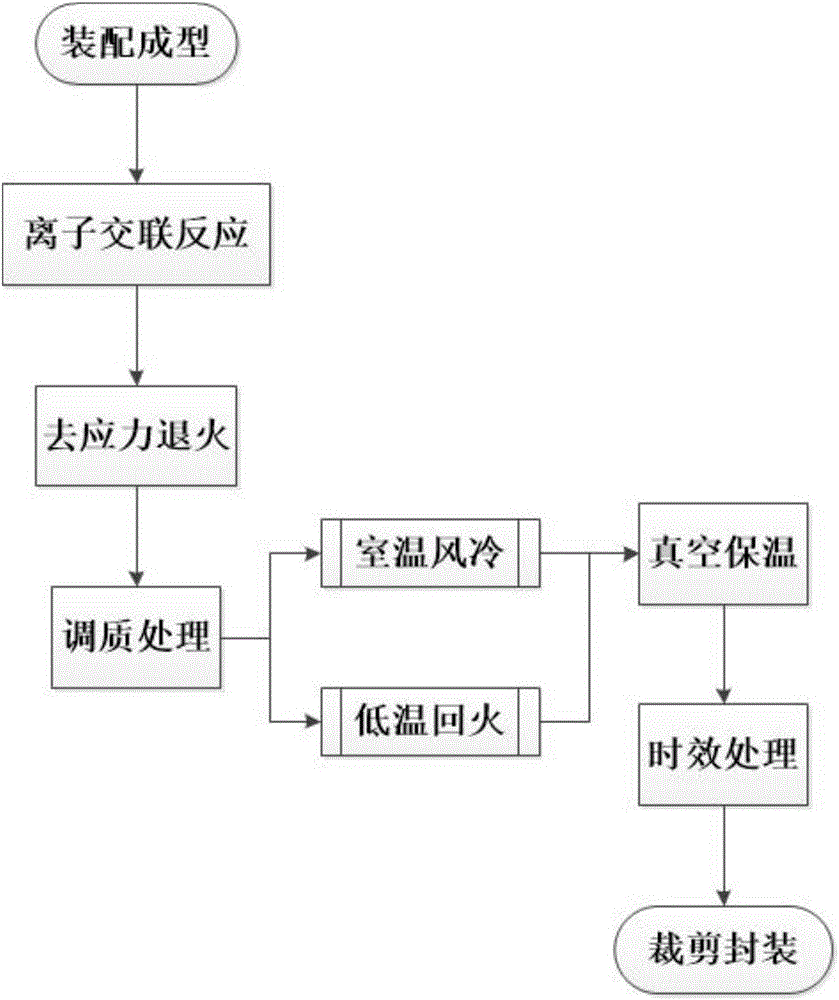

[0018] A heat treatment process flow chart for processing CAH artificial muscles, such as figure 1 As shown, the process is mainly that the artificial muscle goes through four stages of cross-linking, heating, heat preservation and cooling in solid state. These processes are connected with each other and complement each other. The CAH artificial muscle is composed of an electric actuator membrane and two electrode membranes. The two electrode membranes are respectively covered on both sides of the electrical actuator membrane, and are fitted together to form an electric actuator similar to a "sandwich" structure. In order to prevent deformation of the artificial muscle during heat treatment, its initial thickness should be uniform, its shape should be symmetrical, and a margin for heat treatment should be reserved to obtain the expec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com