Corrosion-resistant and wear-resistant ABS modified plastic

A wear-resistant and corrosion-resistant technology, applied in the field of ABS modified plastics, can solve the problems of high performance, corrosion resistance, poor wear resistance, limited and other problems, and achieve good compatibility, dispersion, and flexibility. , no toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

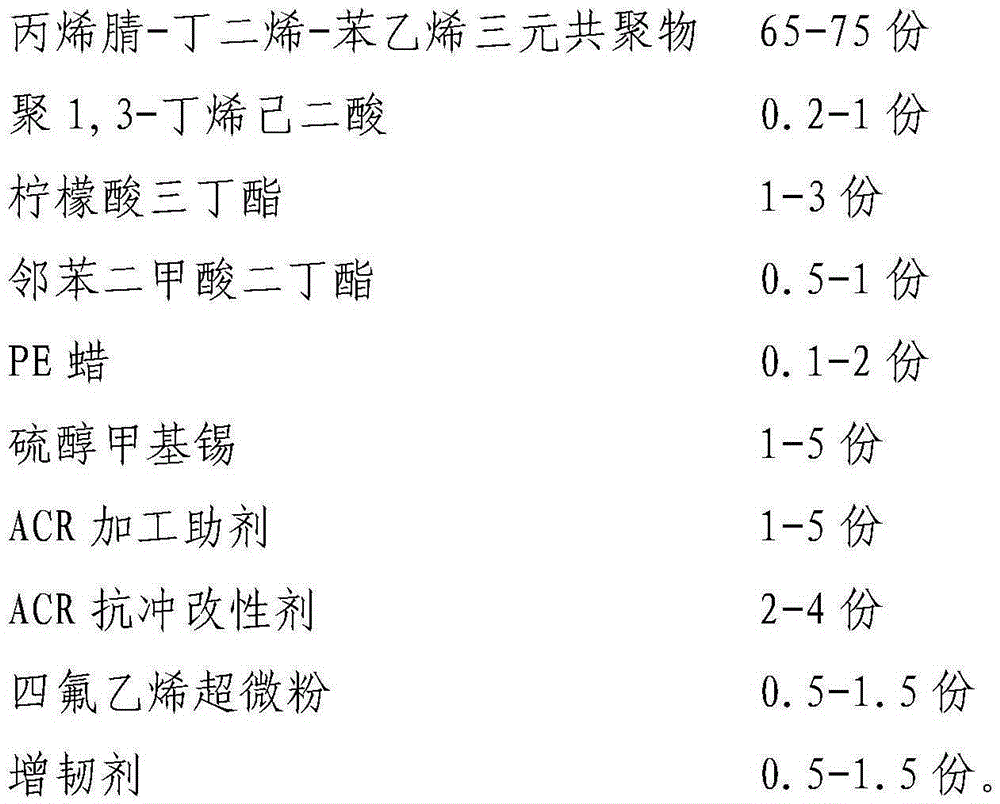

[0016] Example 1: The present invention provides a corrosion-resistant and wear-resistant ABS modified plastic, including: 60-70 parts of acrylonitrile-butadiene-styrene terpolymer, poly-1,3-butene adipate 0.1-1 part, 1-2 parts of tributyl citrate, 0.5-1 part of dibutyl phthalate, 0.1-2 parts of PE wax, 1-5 parts of methyl tin mercaptide, 1-5 parts of ACR processing aid 2-3 parts of ACR impact modifier, 0.5-1.5 parts of tetrafluoroethylene superfine powder, and 0.5-1.5 parts of toughening agent.

Embodiment example 2

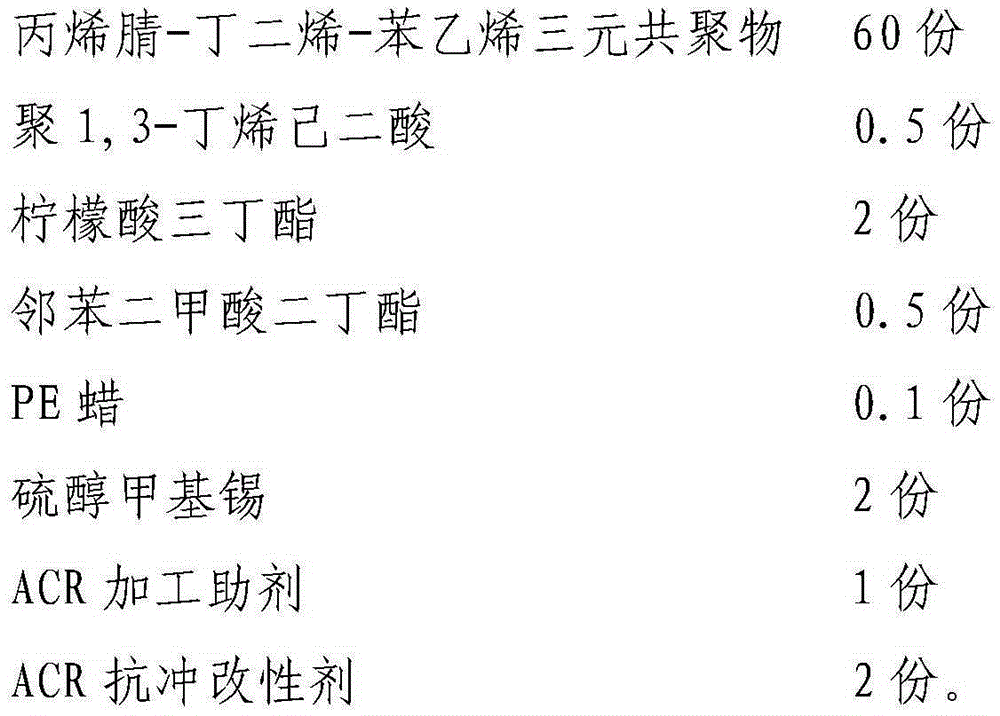

[0017] Example 2: The corrosion-resistant and wear-resistant ABS modified plastic includes the following parts by weight: 60 parts of acrylonitrile-butadiene-styrene terpolymer, 0.5 part of poly-1,3-butene adipate, 1.5 parts of tributyl citrate, 0.5 parts of dibutyl phthalate, 0.1 parts of PE wax, 2 parts of methyl tin mercaptide, 1 part of ACR processing aid, 2 parts of ACR impact modifier.

Embodiment example 3

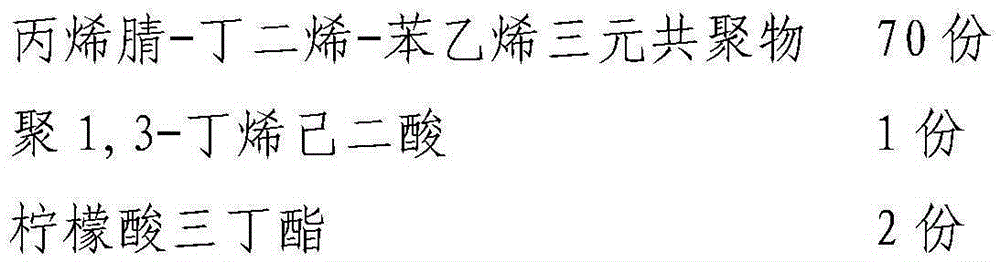

[0018] Example 3: The corrosion-resistant and wear-resistant ABS modified plastic includes the following materials in parts by weight: 70 parts of acrylonitrile-butadiene-styrene terpolymer, 1 part of poly-1,3-butene adipate, 2 parts of tributyl citrate, 1 part of dibutyl phthalate, 2 parts of PE wax, 5 parts of methyl tin mercaptide, 5 parts of ACR processing aid, 3 parts of ACR impact modifier.

[0019] The preparation method includes the following steps: weighing the materials, stirring them evenly to obtain a mixture; adding the mixture into a twin-screw extruder, and the processing temperature of the twin-screw extruder: the temperature in the first zone is 160-170°C, and the temperature in the second zone is 180-180°C. 185°C, the temperature in the third zone is 195-215°C, the temperature in the fourth zone is 250-255°C, the temperature in the fifth zone is 235-245°C, the temperature in the sixth zone is 215-220°C, the temperature in the seventh zone is 225-235°C, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com