Process for preparing unidirectional moisture-permeable light heat-insulating tatting double-layer fabric

A double-layer fabric and one-way moisture-wicking technology, which can be applied to fabric surface trimming, weaving, fabric, etc., can solve the problems of insufficient use of polypropylene and poor quick-drying performance, and achieve good moisture absorption and quick-drying performance, light weight, and warmth retention. better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

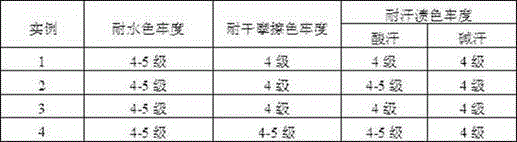

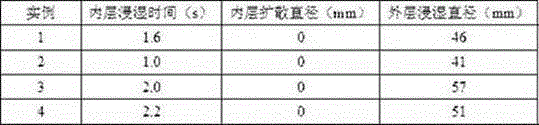

Examples

Embodiment 1

[0022] A preparation process for a unidirectional moisture-wicking lightweight warm-keeping woven double-layer fabric, comprising the following steps:

[0023] Step S1, designing the fabric weave: adopt double-layer woven structure, the warp yarns are interwoven with the surface and weft through the method of "internal warp binding", the surface layer is made of plain weave, and the inner layer is brushed;

[0024] Step S2, select the yarn: the surface layer of the double-layer fabric selects polyester special-shaped cross-section water-absorbing DTY yarn with a fineness of 75D / 72F, and the inner layer selects DTY polypropylene hollow dyed yarn with a fineness of 75D / 72F;

[0025] Step S3, pre-treatment of gray fabric: adopt cold stack desizing process, caustic soda 50g / L, accelerator 1.2g / L, desizing temperature at 90°C, process for 60min, wash with water at 95°C;

[0026] Step S4, gray cloth dyeing: using disperse dye overflow tank dyeing process, the dyeing temperature is c...

Embodiment 2

[0029] A preparation process for a unidirectional moisture-wicking lightweight warm-keeping woven double-layer fabric, comprising the following steps:

[0030] Step S1, fabric weave design: double-layer woven structure is adopted, the warp yarns are interwoven with the surface and weft through the method of "internal warp binding", the surface layer is made of plain weave, and the inner layer is brushed;

[0031] Step S2, select the yarn: the surface layer of the double-layer fabric selects cool silk cotton yarn with a fineness of 16S, and the inner layer selects DTY polypropylene hollow dyed yarn with a fineness of 75D / 72F;

[0032] Step S3, pre-treatment of gray fabric: adopt cold stack desizing process, caustic soda 55g / L, accelerator 1.5g / L, desizing temperature at 95°C, process for 60min, wash with water at 95°C;

[0033] Step S4, gray cloth dyeing: using disperse dye overflow cylinder dyeing process, the dyeing temperature is controlled at 140°C;

[0034] Step S5, finis...

Embodiment 3

[0036] A preparation process for a unidirectional moisture-wicking lightweight warm-keeping woven double-layer fabric, comprising the following steps:

[0037] Step S1, fabric weave design: double-layer woven structure is adopted, the warp yarns are interwoven with the surface and weft through the method of "internal warp binding", the surface layer is made of plain weave, and the inner layer is brushed;

[0038] Step S2, select the yarn: the surface layer of the double-layer fabric selects polyester special-shaped cross-section water-absorbing DTY yarn with a fineness of 30D / 48F, and the inner layer selects DTY polypropylene hollow dyed yarn with a fineness of 50D / 72F;

[0039] Step S3, pre-treatment of gray fabric: adopt cold stack desizing process, caustic soda 45g / L, accelerator 1.0g / L, desizing temperature at 85°C, treatment for 60min, wash with water at 95°C;

[0040] Step S4, gray cloth dyeing: using disperse dye overflow cylinder dyeing process, the dyeing temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com