A method for manufacturing fluffy hand tissue paper

A technology for household paper and manufacturing method, applied in special paper, papermaking, paper and other directions, can solve the problem of difficult to achieve the fluffy feel of household paper, improve water storage capacity and cleaning ability, feel soft and skin-friendly, and operate handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

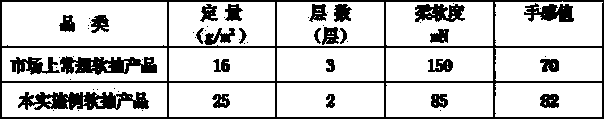

[0018] A fluffy household tissue paper, using 100% bamboo fiber pulp, is a crepe tissue paper produced by a single-cylinder rotary screen household paper machine, and is a semi-finished two-layer tissue paper with a single-layer basis weight of 25g / m².

[0019] Manufacturing process operations mainly include:

[0020] (1) The bamboo pulp used in the single-cylinder rotary screen household paper machine has a beating degree of 35°SR. During the beating process, Hercobond8922 beating enzyme is added at 0.1 kg / ton of pulp, and Hercobond7550 dry strength agent is added at 1.5 kg / ton of pulp.

[0021] (2) The basis weight of the single-cylinder rotary screen tissue paper machine is 25 g / m², and the crepe rate is 18%.

[0022] (3) The semi-finished paper is sanded on the outside of the paper using a sanding machine.

[0023] (4) The semi-finished paper after sanding finishing is rewound or folded, slitting, and then packaged to obtain a finished product of fluffy hand tissue paper ...

Embodiment 2

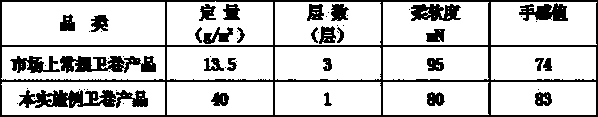

[0028] A kind of fluffy tissue paper for daily use, using 30% coniferous wood fiber and 70% bamboo fiber mixed pulp, and using a crescent-shaped high-speed tissue paper machine to produce crepe tissue paper, with a single layer basis weight of 40g / m²1 Ply toilet paper semi-finished paper.

[0029] Manufacturing process operations mainly include:

[0030] (1) The crescent-shaped high-speed household paper machine uses 30% coniferous wood fiber and 70% bamboo fiber mixed pulp with a knocking degree of 35°SR. During the beating process, 1.5 kg / ton of Hercobond7550 dry strength agent is added.

[0031] (2) Crescent-shaped high-speed tissue paper machine has a basis weight of 40 g / m² and a crepe rate of 18%.

[0032] (3) The semi-finished paper is needled and finished on both sides of the paper at the same time using a needle punching machine.

[0033] (4) The semi-finished paper after needling finishing is rewound or folded, cut and packaged to obtain a finished product of fluff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com