Snow melting system for asphalt concrete pavement

An asphalt concrete and snow-melting technology, applied to roads, roads, pavement details, etc., can solve problems such as endangering farmland green belts, shortening road life, polluting the environment, and achieving energy shortages and environmental pollution. high heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

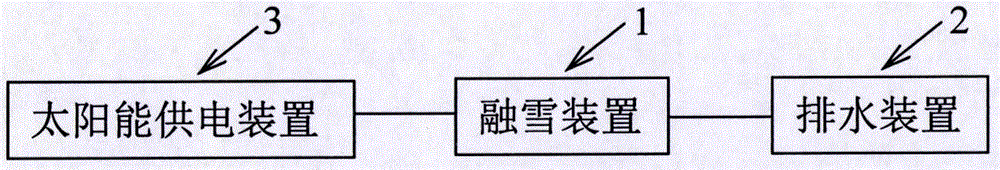

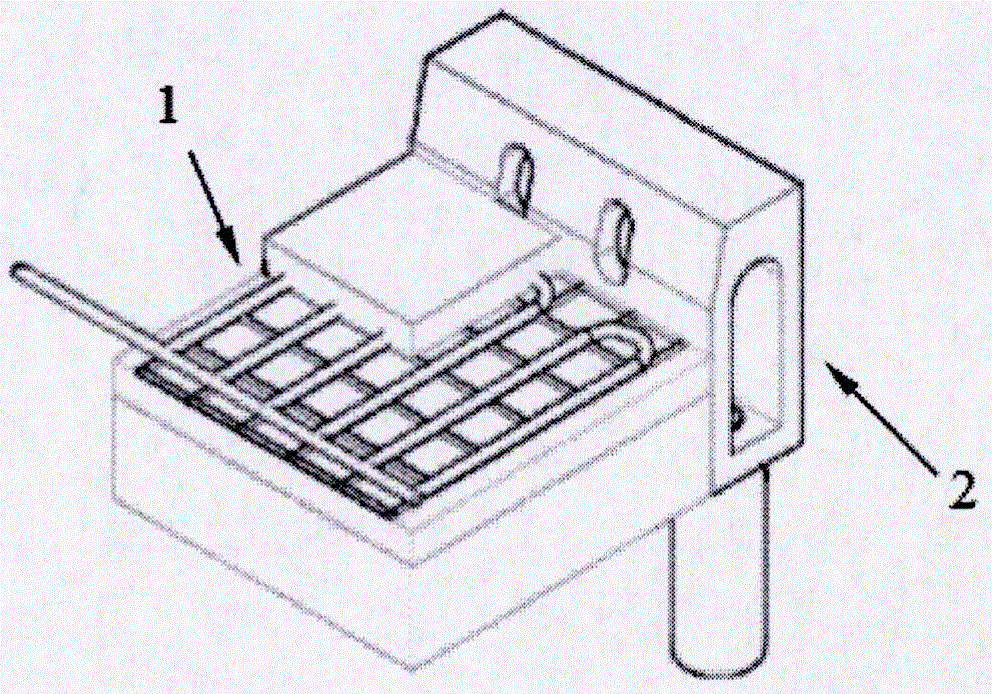

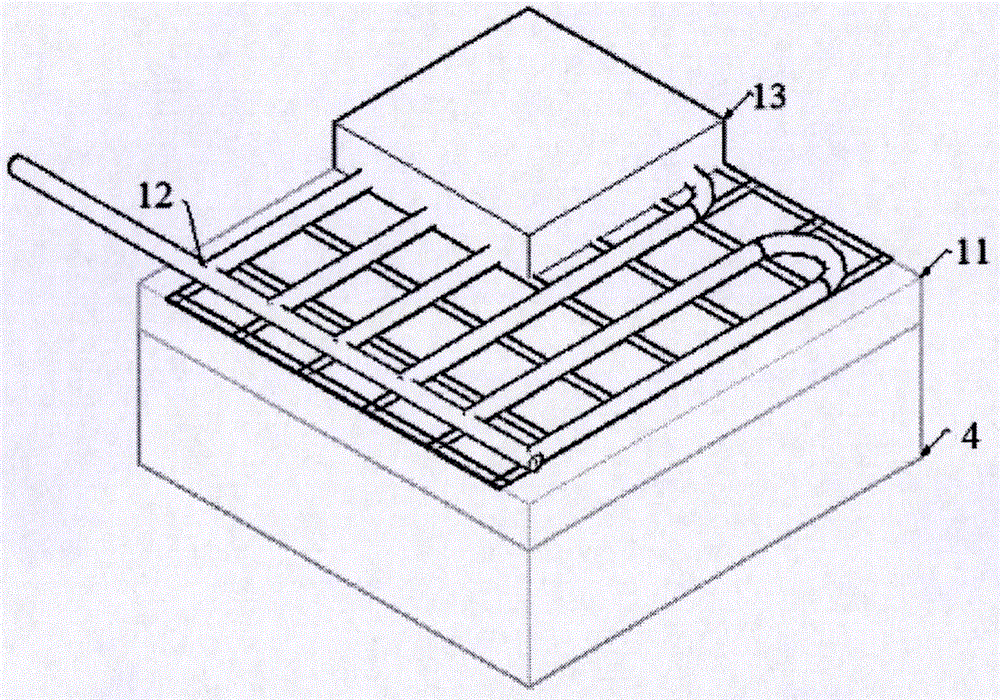

[0040] A snow melting system for asphalt concrete pavement, such as Figure 1-3 As shown, it includes a snow melting device 1, a drainage device 2 and a power supply device. In this embodiment, the power supply device is a solar power supply device 3; the snow melting device 1 is laid on the roadbed 4 and is electrically connected to the solar power supply device 3; The drainage device 2 is partly located on the road surface and partly located under the road surface, and is in close contact with the snow melting device 1 ; the ice and snow on the road surface is discharged into the ground through the drainage device 2 after being melted by the snow melting device 1 .

[0041] Specifically, the drainage device 2 is located at the lowest end of the road surface slope extension direction, so that the melted snow water can flow into the drainage device along the road surface slope direction from high to low. Generally speaking, there are multiple drainage devices, which can be even...

Embodiment 2

[0046] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the snow melting system also includes a monitoring device 5, and the monitoring device 5 includes an infrared thermal imager 51, a video monitor 52, a microprocessor 53 and a power distribution control box 54, the infrared thermal imager 51, the video monitor 52, and the microprocessor 53 are all electrically connected to the power distribution control box 54, and the power distribution control box 54 is electrically connected to the solar power supply device 3; the infrared thermal imager 51 and video monitor 52 are used to image the snowmelt condition on the road surface, and the imaging data is transmitted to the microprocessor 53 through the wireless communication device 55, and the microprocessor 53 processes the imaging data and transmits the processing result to the power distribution control Box 54 , the power distribution control box 54 is connected with the snow melting...

Embodiment 3

[0048] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 2 is that the bottom of the drain main body 21 is also provided with a second heating wire 213, and the second heating wire 213 is partially buried in the drain main body 21, and part of it is exposed and It is connected with the second cable 214, and the second cable 214 is connected with the solar power supply device 3. The reason for embedding the second heating line 213 at the bottom of the drain main body 21 in this embodiment is that in the severe cold region of the north, the aboveground temperature can reach -20°C to -30°C in winter, and the area within 2m underground is below zero, and the snow After water enters the gutter, it may freeze again and block the water outlet 212. Therefore, a second heating line 213 is embedded near the water outlet 212 at the bottom of the gutter main body 21 to melt the ice and snow in the gutter and make the gutter drain. unobstructed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com