A bathroom pipeline integrated waterproof chassis

A technology for toilets and chassis, applied in buildings, building components, building insulation materials, etc., can solve the problem of the large difference in the lifting volume between reinforced concrete and fine stone concrete, waste of building effective floor height, and can not completely solve the problem of "inter-floor". Maintenance interference and other problems, to achieve the effect of eliminating maintenance interference between layers, conducive to environmental protection, energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

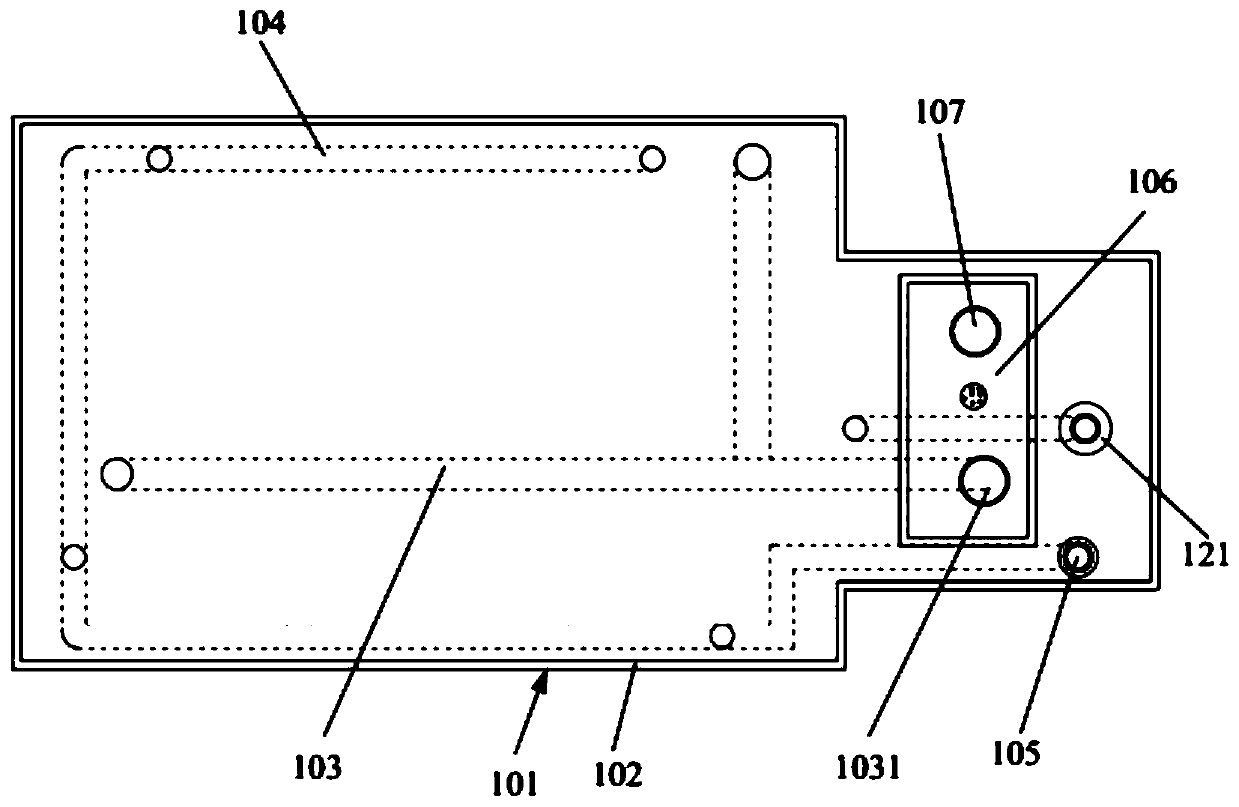

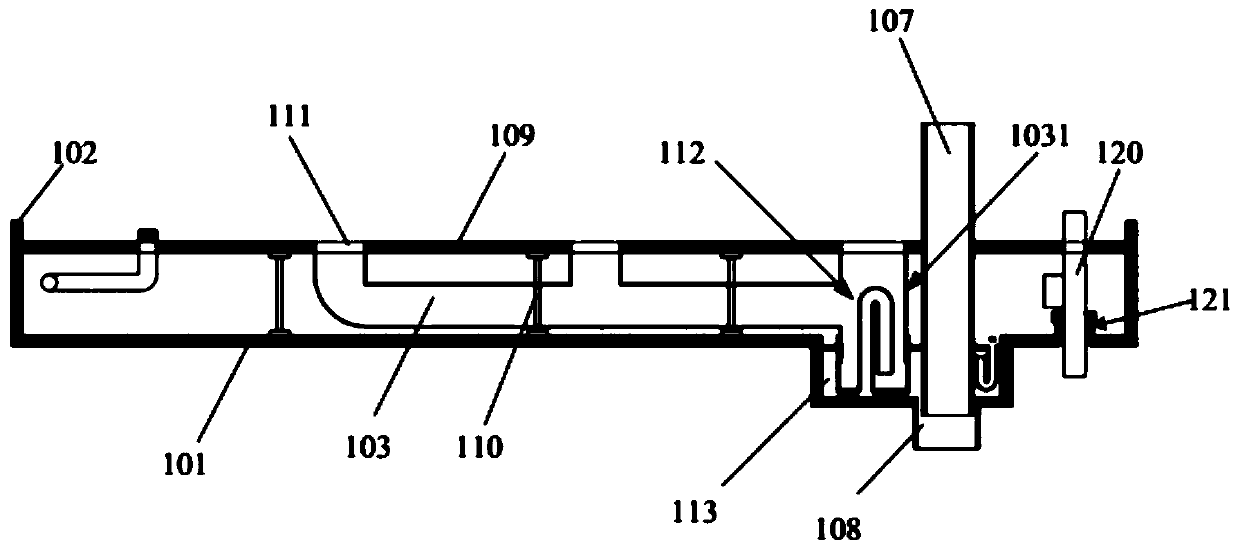

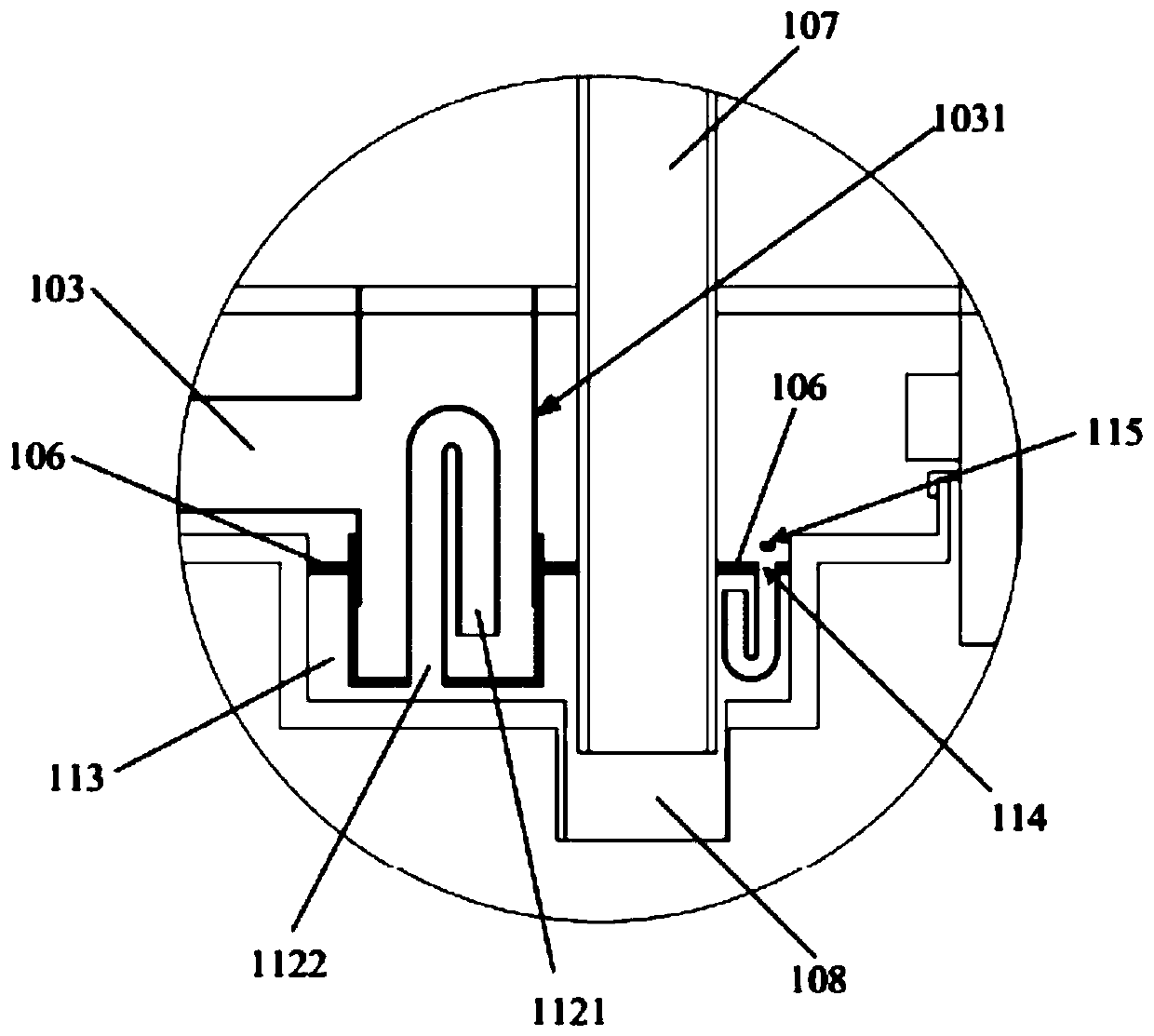

[0037] like figure 1 Shown is a sectional view of the waterproof chassis of an embodiment of the present invention, figure 2 Shown is a sectional view of the waterproof chassis of an embodiment of the present invention, image 3 Shown is an enlarged view of the catchment groove of an embodiment of the present invention, as Figure 4 A schematic diagram of a standpipe inserted into a standpipe casing according to an embodiment of the present invention. to combine Figure 1 to Figure 4 To explain the content of the present invention, in order to clearly explain the content of the present invention, firstly, an overall description is given to the place where the present invention is applied to the toilet. The toilet pipeline integrated waterproof chassis provided by the present invention includes a waterproof bottom plate 101, and The edge 102 formed on the edge of the waterproof bottom plate 101 is upward. The toilet decorative floor 109 is erected above the waterproof chas...

Embodiment 2

[0047] like Figure 5 Shown is a plan view of another embodiment of the waterproof chassis of the present invention, Image 6 Shown is a sectional view of another embodiment of the waterproof chassis of the present invention. The difference between this embodiment and the embodiment is that a toilet drain pipe 217 is provided. The following is a detailed explanation. According to the present invention, a bathroom pipeline integrated waterproof chassis includes a waterproof bottom plate 201 and a rib 202 formed upward along the edge of the waterproof bottom plate 201 . The toilet decorative floor 209 is erected above the waterproof chassis. In this embodiment, the decorative floor 209 is erected on the waterproof chassis through the support 210 of the decorative floor 209 . It should be understood that, in order to make the water in the bathroom flow smoothly to the floor drain opening 211, the rib 202 is higher than the floor laid above the waterproof chassis. In this embodi...

Embodiment 3

[0055] like Figure 7 Shown is a plan view of another embodiment of the waterproof chassis of the present invention, Figure 8 shown Figure 7 A-A sectional view of the sewage pipe of the waterproof chassis toilet. The difference between this embodiment and the second embodiment is that the toilet sewage pipe 317 is partially installed in the sealed cavity 313 . The following is a detailed explanation. According to the present invention, a bathroom pipeline integrated waterproof chassis includes a waterproof bottom plate 301 and a rib 302 formed upward along the edge of the waterproof bottom plate 301 . The decorative floor 309 of the bathroom is erected above the waterproof chassis. In this embodiment, the decorative floor 309 is erected on the waterproof chassis through the supports 310 that elevate the decorative floor 309 .

[0056] According to a bathroom pipeline integrated waterproof chassis provided by the present invention, the waterproof bottom plate 301 forms a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com