Dynamic and automatic pumping unit balance adjusting device

A technology of balance device and pumping unit, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc. It can solve the problems of inability to adjust the balance of the device, low liquid utilization rate, liquid evaporation and pollution, etc., to achieve The effect of saving electric energy, reducing production and management costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

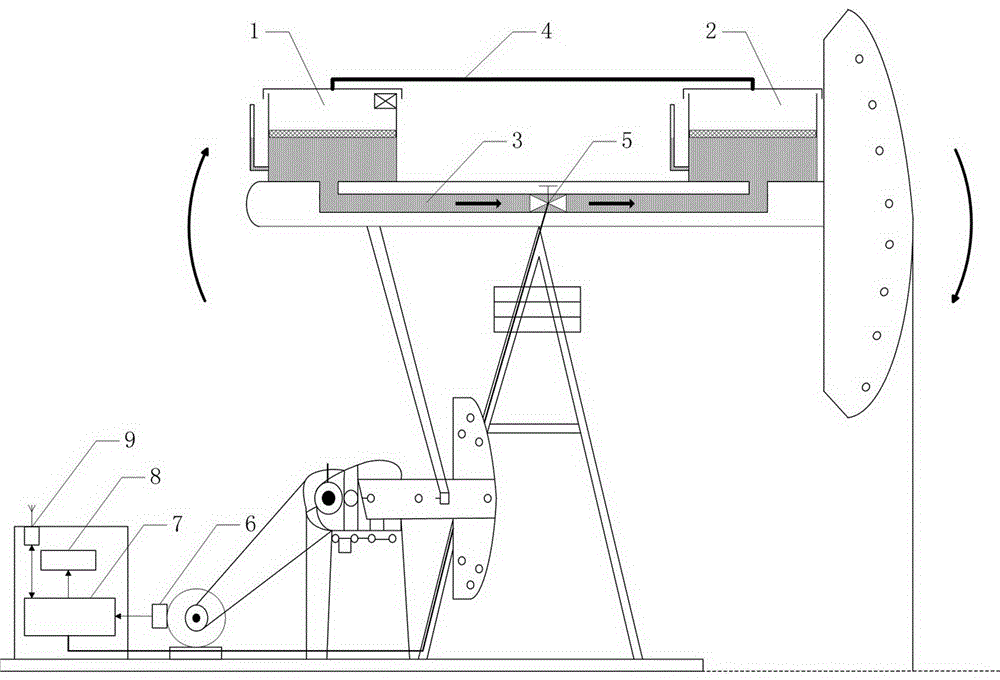

[0028] Specific embodiment one: as figure 1 Shown is the non-stop adjustment method using the gravitational potential energy when the electric control valve (5) is used. The electric control valve (5) of the device is installed on the catheter (3). The current measurement module (6) is generally a current transformer, which collects the real-time working current of the motor of the pumping unit and sends it to the main control module (7). The main control module (7) is generally an ordinary single-chip microcomputer and its peripheral circuits. , also includes a relay to control the on-off of the driving power of the electronically controlled valve (5).

[0029] The main control module (7) calculates the upward current and the downward current, and obtains the real-time balance degree of the pumping unit based on this. Compared with the set balance degree, if it exceeds the threshold value, the liquid needs to be pumped from the first liquid storage tank (1 ) to the second l...

specific Embodiment 2

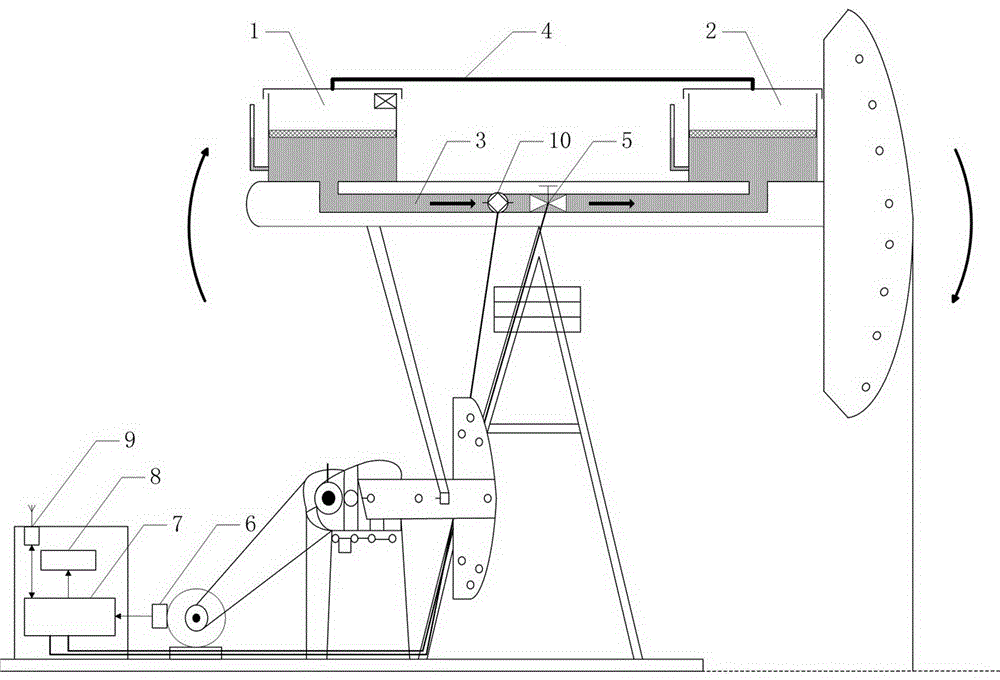

[0033] Specific embodiment two: as figure 2 Shown is the non-stop adjustment method utilizing the electronically controlled valve (5) and the two-way water pump (10). A two-way water pump (10) is installed on the catheter tube (3) of the device, and the electric control valve (5) is installed on the catheter tube (3). The current measurement module (6) collects the real-time working current of the motor of the pumping unit, and sends it to the main control module (7) to calculate the upstream current and the downstream current, so as to obtain the real-time balance degree of the pumping unit and the set balance degree In comparison, if the threshold is exceeded and the liquid volume of the first liquid storage tank (1) needs to be increased, the main control module (7) opens the electronically controlled valve (5), starts the two-way water pump (10), and controls the flow of the two-way water pump (10). The direction of rotation makes the liquid flow from the second liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com