A Trenchless Pipe Curtain Method Using Curved Pipe Shed

A non-excavation, pipe shed technology, applied to mining equipment, earthwork drilling, shaft equipment, etc., can solve problems such as low construction efficiency, obstructing smooth traffic, and damaging the environment, so as to improve construction safety and reduce surface excavation , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

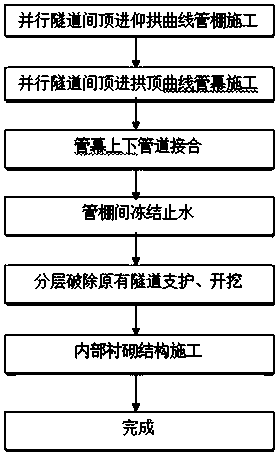

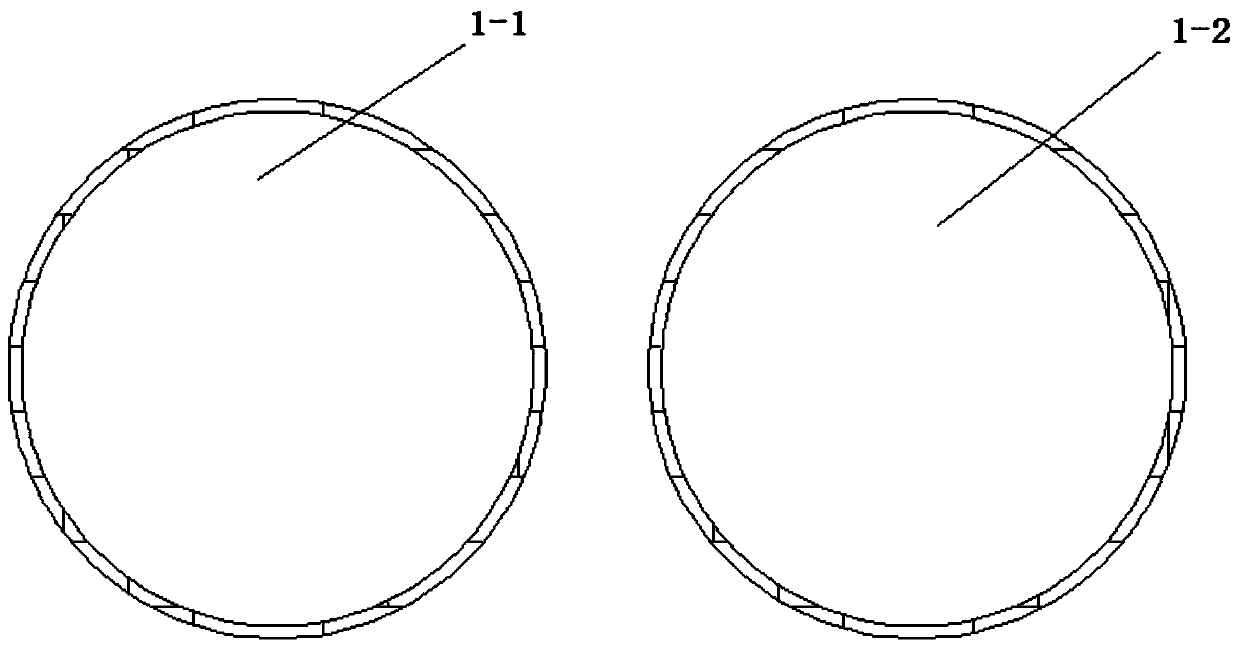

[0043] Example 1: Underground converging road section where highway shield tunnels run parallel

[0044] Such as Figure 1-7 as shown, figure 1 It is two road shield tunnels 1-1 and 1-2 side by side; figure 2 For the construction of the curved pipe curtain 2-2 of the inverted arch, the reaction force frame 2-1 is set in the shield tunnel on one side, and the pipe jacking construction is carried out to the shield tunnel on the other side. During the construction, the front end of the pipe jacking machine is a miniature shield machine. The segment at the starting point of the pipe jacking is made of special FRP profile, which is convenient for cutting and ensures that the segment has sufficient supporting capacity;

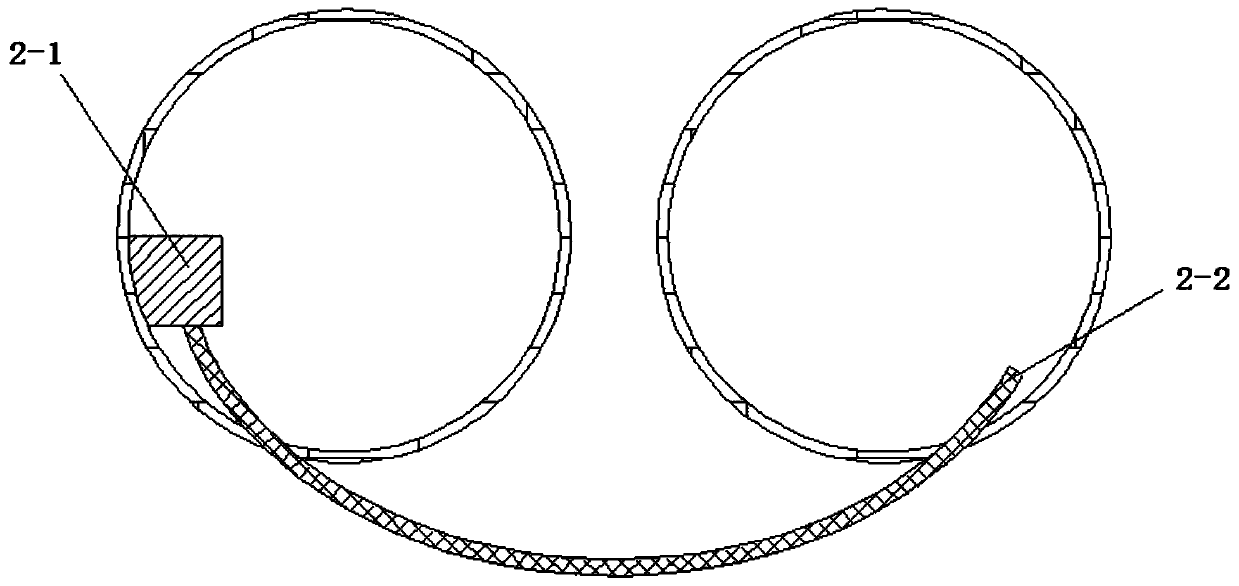

[0045] image 3 For the construction of the vault pipe curtain 3-2, which is similar to the construction of the inverted arch pipe curtain, the reaction force frame 3-1 is set in the shield tunnel on one side, and the pipe jacking construction is carried out to...

Embodiment 2

[0049] Example 2: Expansion and excavation of the subway shield tunnel into a subway station

[0050] Such as Figure 7-11 as shown, Figure 7 It is two side-by-side subway shield tunnels 7-1 and 7-2, and it is planned to build an island station between the two tunnels; Figure 8 For the construction of the curved pipe curtain 8-2 of the inverted arch, the reaction frame 8-1 is set in the shield tunnel on one side, and the pipe jacking construction is carried out to the shield tunnel on the other side. During the construction, the front end of the pipe jacking machine is a miniature shield machine. The segment at the starting point of the pipe jacking is made of special FRP profile, which is convenient for cutting and ensures that the segment has sufficient supporting capacity;

[0051] Figure 9 For the construction of the vault pipe curtain 9-1, similar to the construction of the inverted arch pipe curtain, the pipe jacking work of the inverted arch and the vault is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com