Automotive fuel assisted heating system and control method thereof

A technology for auxiliary heating and control methods, applied in heating/cooling equipment, coolant flow control, vehicle components, etc., can solve the problems of low heat exchange efficiency, lack of flexibility, large pump loss, etc. Interesting, minimal-changing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

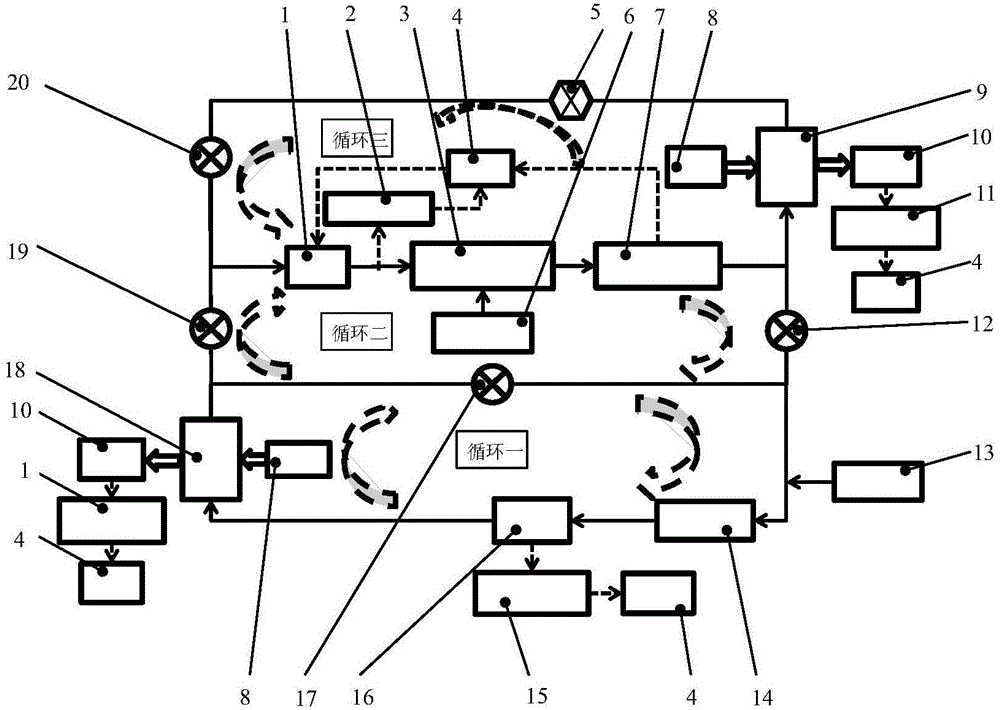

[0017] Attached below figure 1 , 2 , 3 further description of the invention.

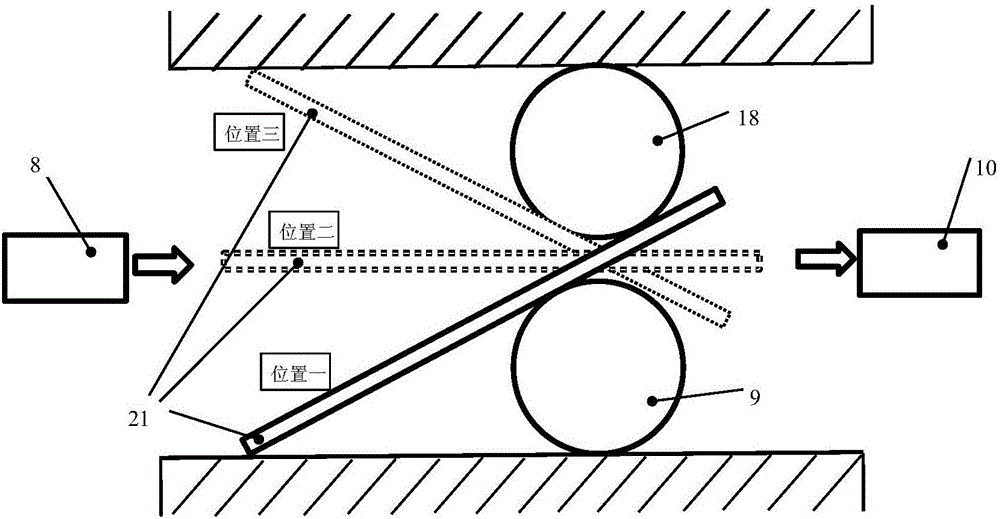

[0018] An automobile fuel auxiliary heating system and its control method, comprising a fuel auxiliary heater 3, an electronic pump 1, an air bubble detection device 7, an auxiliary fuel tank 6, a radiator one 18, a radiator two 9, a fan 8, an ECU 4, and a temperature sensor comprising 2, 11, 15, solenoid valves include 12, 17, 19, 20, pressure balance valve 5, baffle plate 21 and other basic configurations of the vehicle cooling system. The fuel auxiliary heater 3 is used to heat the coolant; the electronic pump 1 is used to drive the coolant, and the power of the electronic pump 1 is controlled by the ECU 4; the bubble detection device 7 is used to detect and judge the cooling of the fuel auxiliary heater 3 Whether the liquid is in the nucleate boiling region; the auxiliary fuel tank 6 is used to provide fuel to the fuel auxiliary heater 3; the fan 8 is used to blow the heat of the radiator one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com