Lead bismuth alloy bubble pump circulation capability experiment system and experiment method thereof

A lead-bismuth alloy, experimental system technology, used in aerodynamic tests, fluid dynamics tests, pump tests, etc., can solve the problems of the lack of experimental loops of the circulation capacity of the bubble pump, and achieve improved safety and a large adjustment range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

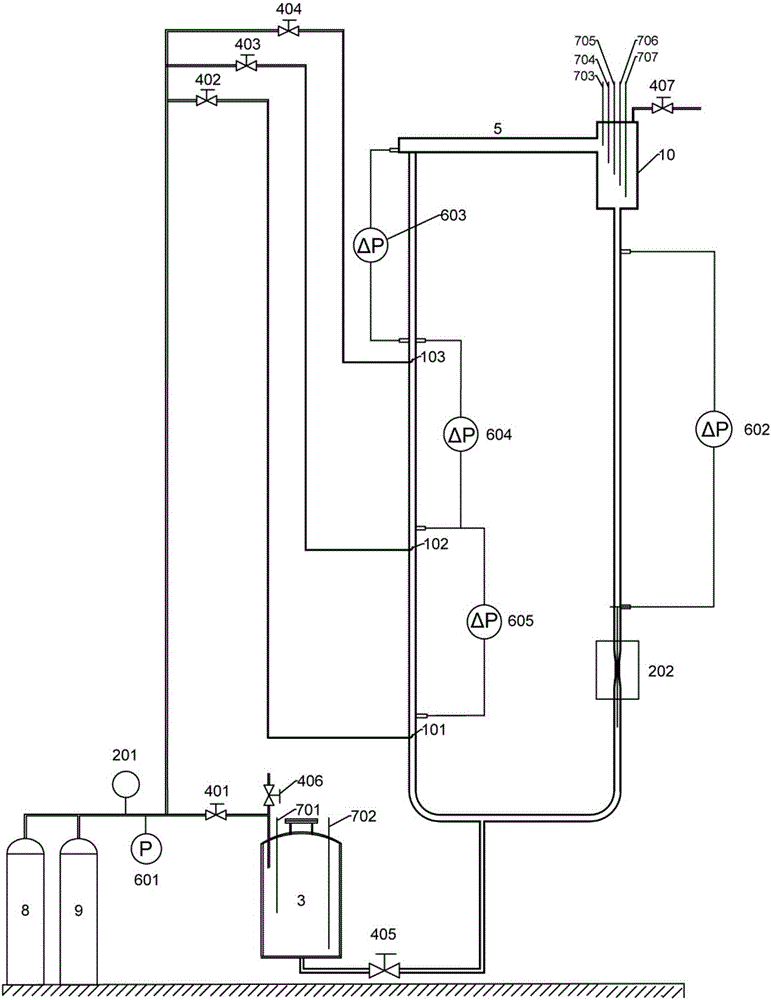

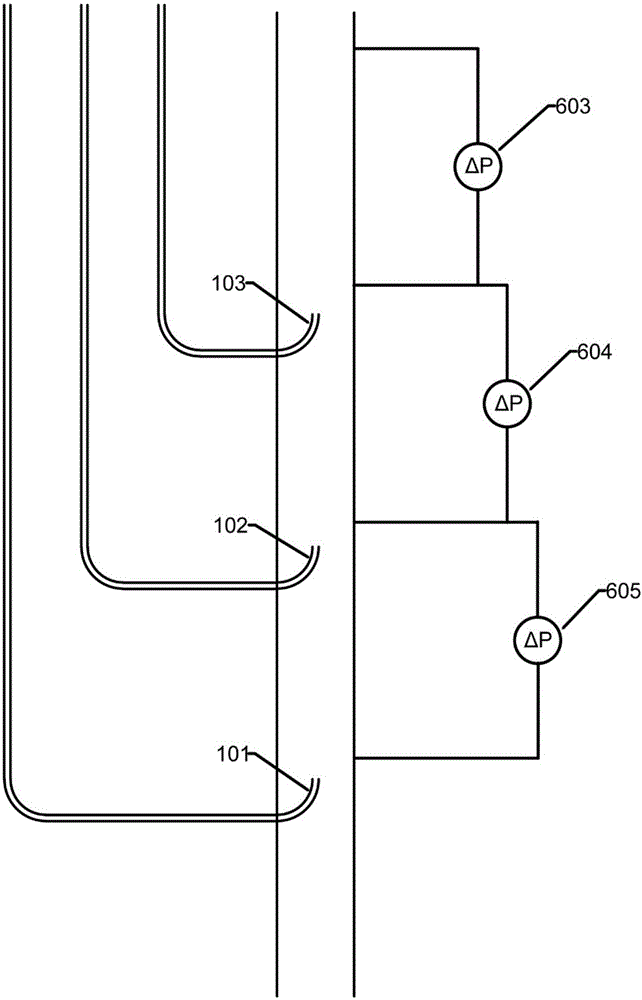

[0030] Such as figure 1 As shown, the present invention is a lead-bismuth alloy bubble pump circulation capability test system, comprising a first high-pressure argon tank 8, a second high-pressure argon tank 9, a first high-pressure argon tank 8 and a second high-pressure argon tank 9 The thermal gas mass flowmeter 201 on the downstream pipeline, the pressure sensor 601 on the downstream pipeline of the thermal gas mass flowmeter 201, the first valve 401, the second valve 402, the third valve 403 and the fourth valve at the downstream of the pressure sensor 601 The valves 404 are connected in parallel. Their functions are to provide argon for the experimental circuit, measure the flow of argon, monitor the pressure in the gas pipeline, adjust the inflow position of argon and adjust the flow of argon. The above constitute the gas module of the system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com