Coal combustion process and combustion furnace thereof

A combustion furnace and process technology, applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of low cycle efficiency, complex equipment, high cost, etc., achieve high combustion temperature, small equipment investment, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

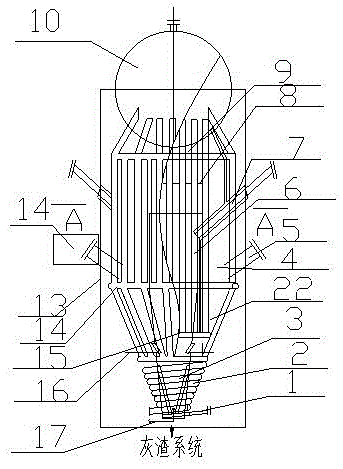

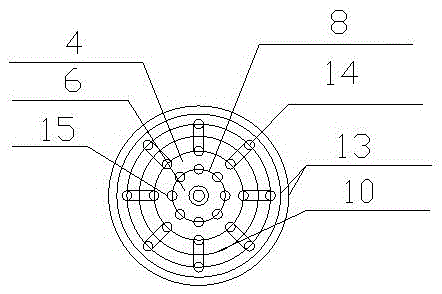

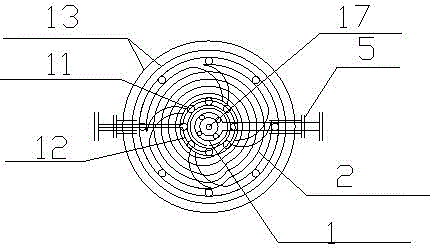

[0025] Embodiment one kind of combustion process of coal, comprises the following steps:

[0026] The first step is to spread the coal in the residual charcoal combustion chamber; the boiler feed water enters the boiler feed water preheater and the heat exchange pipe of the water wall to keep the pipe in a water-filled state, and the steam vent valve is vented; the return valve is closed;

[0027] Step 2: Pass the process air through the oxygen nozzle, and turn on the induced draft fan to ensure the slight positive pressure in the furnace.

[0028] Step 3: Use start-up gas to raise the temperature in the middle of the furnace to 750°C, and raise the temperature at the bottom of the furnace to 650~850°C; feed coal from the raw coal pipeline, and close the start-up gas after most of the coal in the furnace is ignited. Reduce coal and control the temperature of the combustion furnace at 800~900°C. After ensuring the heat storage and culture material layer in the furnace, inject s...

Embodiment approach 2

[0033] Embodiment 2, based on Embodiment 1, as a preference, the third step ensures that the oxygen content in the combustion chamber is between 85% and 100%.

Embodiment approach 3

[0034] Embodiment 3, based on Embodiment 2, as a preference, the third step ensures that the oxygen content in the combustion chamber is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com