Liquid extraction device and liquid extraction method for low water-binder ratio concrete

A liquid phase extraction and water-to-binder ratio technology, which is used in measuring devices, sampling, instruments, etc., can solve the problems of inaccurate results and inability to squeeze the liquid phase of concrete, and achieves convenient operation, efficient collection and sealed preservation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

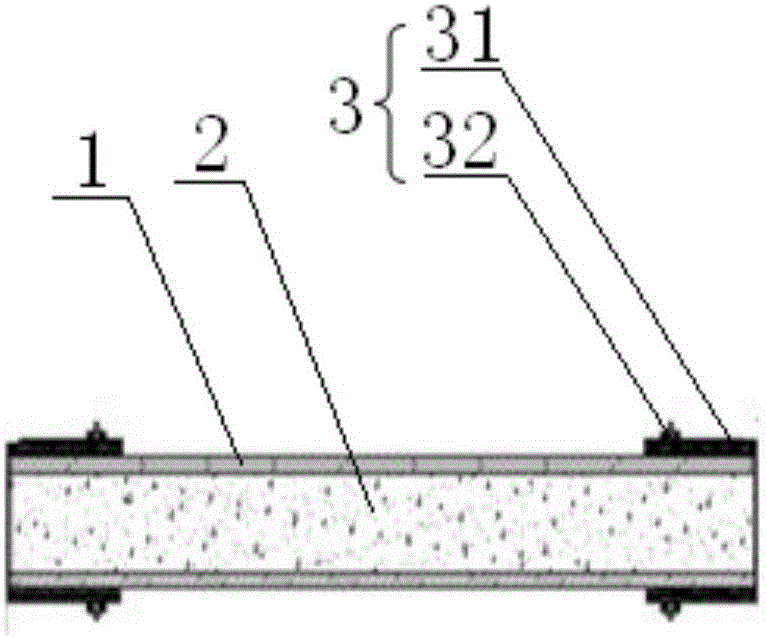

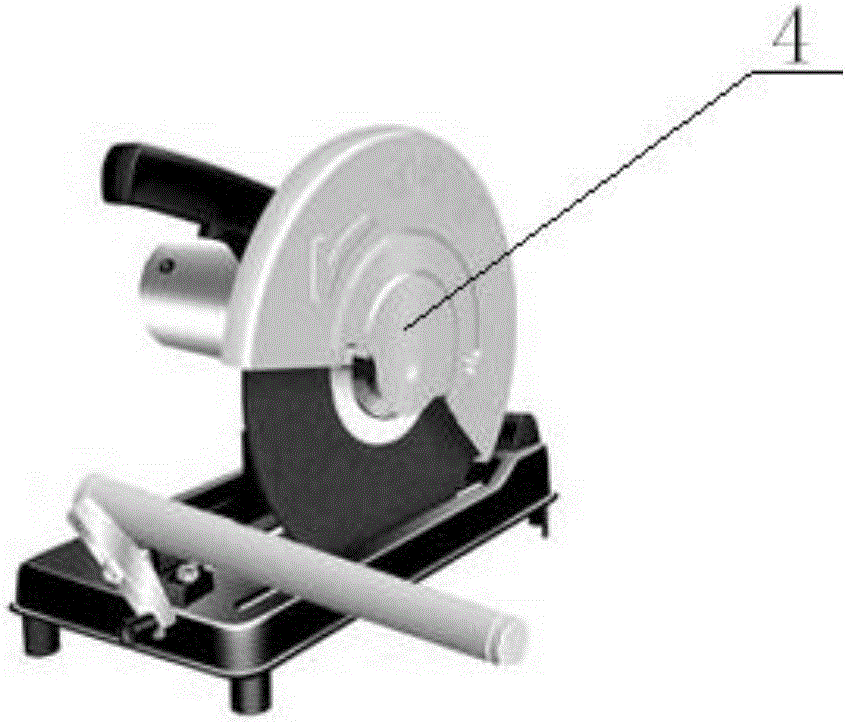

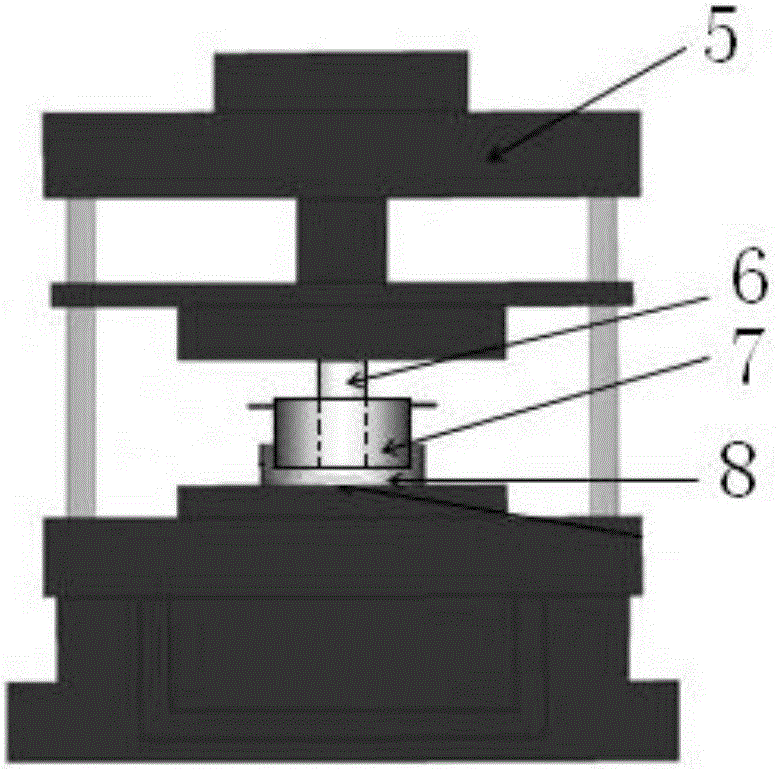

[0053] Use P.I52.5 Portland cement, tap water. Mixing ratio (g): cement-1300, water-520

[0054] First install the sealing ring at one end of the low water-binder ratio concrete forming mold, inject the freshly mixed low water-binder ratio concrete (water-cement ratio 0.4) into the low water-binder ratio concrete forming mold from one end, and then add the sealing ring after vibrating and compacting; Take it out after 60 days of standard maintenance, cut the mold of the sample belt into a suitable small section in the cutting machine, and demold it for use; spray the lubricant on the power transmission shaft and the sample chamber; assemble the plastic in the electro-hydraulic pressure testing machine in turn. Cup, base, water system filter, sample chamber, sample and force transmission shaft, start the electro-hydraulic pressure testing machine to apply pressure, wait for the liquid phase to flow into the plastic cup, and then use the vacuum liquid phase integrator to process...

Embodiment 2

[0065] Use P.I52.5 Portland cement, tap water. Mixing ratio (g): cement-1300, water-390

[0066] First, install the sealing ring at one end of the low water-binder ratio concrete forming mold, inject the freshly mixed low water-binder ratio concrete (water-cement ratio 0.3) into the low water-binder ratio concrete forming mold from the other end, and add the sealing ring after vibrating and compacting; Take it out after 28 days of standard maintenance, cut the mold of the sample belt into a suitable small section in the cutting machine, and demould it for use; spray the lubricant on the power transmission shaft and the sample chamber; assemble the plastic cup in the electro-hydraulic pressure testing machine in turn , base, water system filter, sample chamber, sample and force transmission shaft, start the electro-hydraulic pressure testing machine to apply pressure, wait for the liquid phase to flow into the plastic cup, and then use the vacuum liquid phase integrator to proc...

Embodiment 3

[0076] Use P.I52.5 Portland cement, tap water. Mixing ratio (g): cement-910, water-390, fly ash 390

[0077] First, install the sealing ring at one end of the low water-binder ratio concrete molding mold, and inject the freshly mixed low water-binder ratio concrete (water-cement ratio 0.3, fly ash content 30%) mixed with 30% fly ash into the low water-binder ratio concrete from the other end. In the water-binder ratio concrete molding mold, add a sealing ring after vibration and tamping; take it out after 28 days of standard maintenance, cut the sample belt mold into suitable small sections in a cutting machine, and demould it for use; spray lubricant on the power transmission shaft and the sample compartment; assemble the plastic cup, base, water system filter, sample compartment, sample and force transmission shaft in the electro-hydraulic pressure testing machine in turn, start the electro-hydraulic pressure testing machine to apply pressure, and wait for the liquid phase t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com