Support vector machine based automatic focusing method of ultrasonic phased arrays of ring welds

An ultrasonic phased array and support vector machine technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices to improve detection accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing.

[0056] Embodiments of the present invention are as follows:

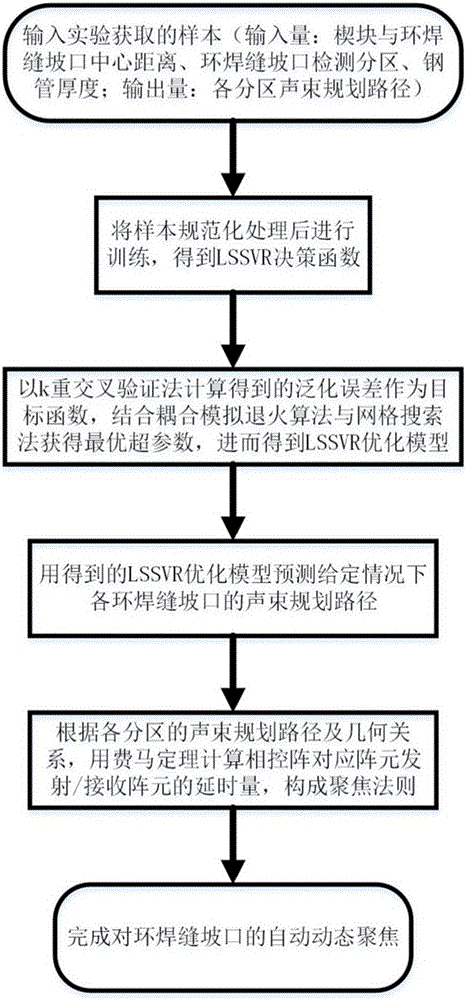

[0057] Such as figure 1 As shown, the present invention utilizes the support vector machine to realize the operation process of ultrasonic phased array intelligent dynamic focusing and can be divided into the following steps:

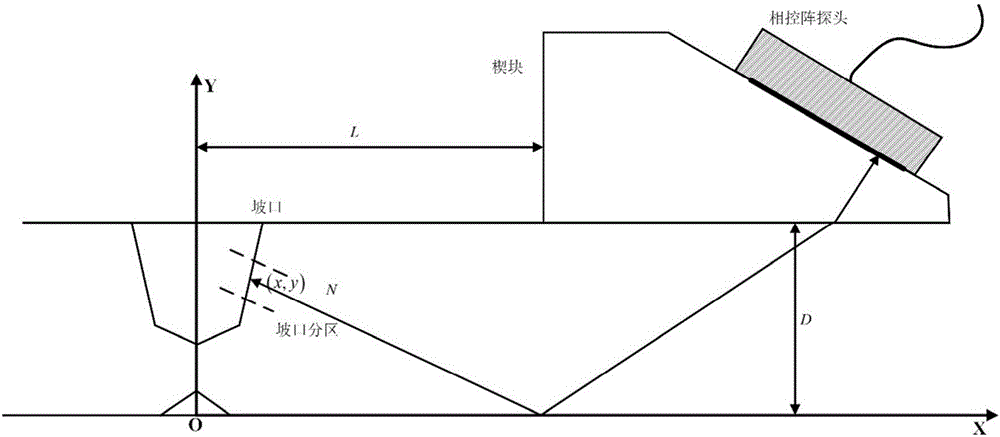

[0058] Step 1, the wedge is assembled on the pipeline, and the phased array probe is arranged on the wedge surface of the wedge. Each parameter such as figure 2 As shown, the distance between the wedge and the center line of the girth weld is determined to be L and the thickness of the steel pipe is D according to the instrument detection. And according to the groove form and wall thickness, the weld scanning area is divided into several layers in the height direction of the groove, the height of each layer is generally 2-3mm, and the groove partitions are numbered N from bottom to top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com