Method for performing multi-parameter synchronous measurement by means of Kelvin probe force microscope

A Kelvin probe force and simultaneous measurement technology, which is applied in the measurement of mechanical properties and surface local potential, and the field of surface topography. problems, to achieve high practical value, high availability and operability, and to compensate for errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

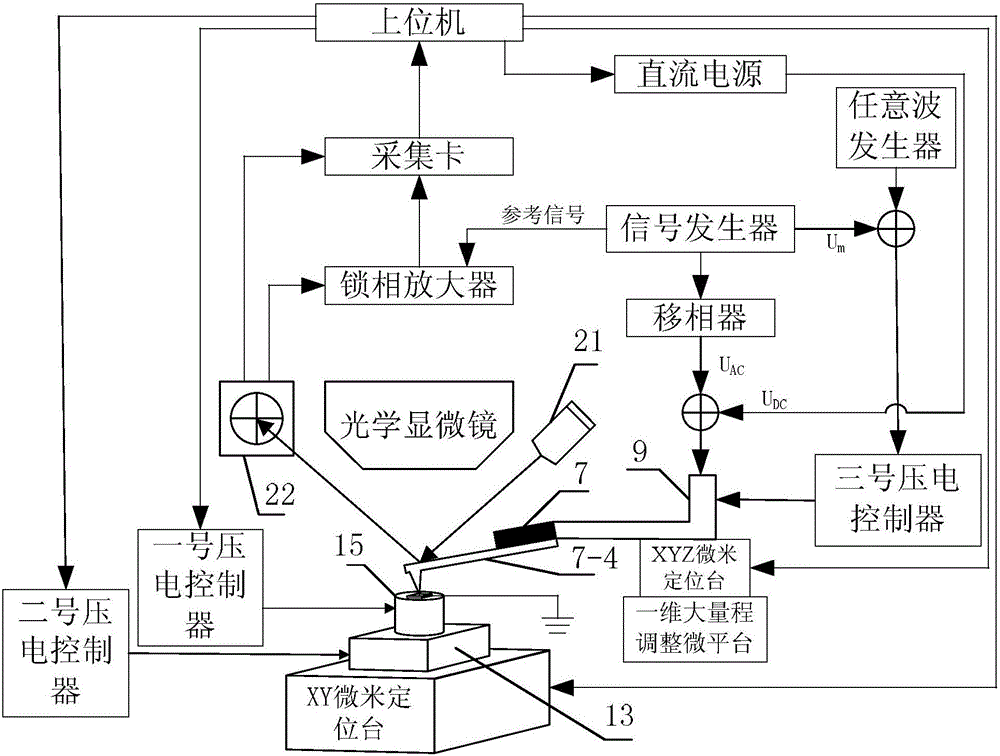

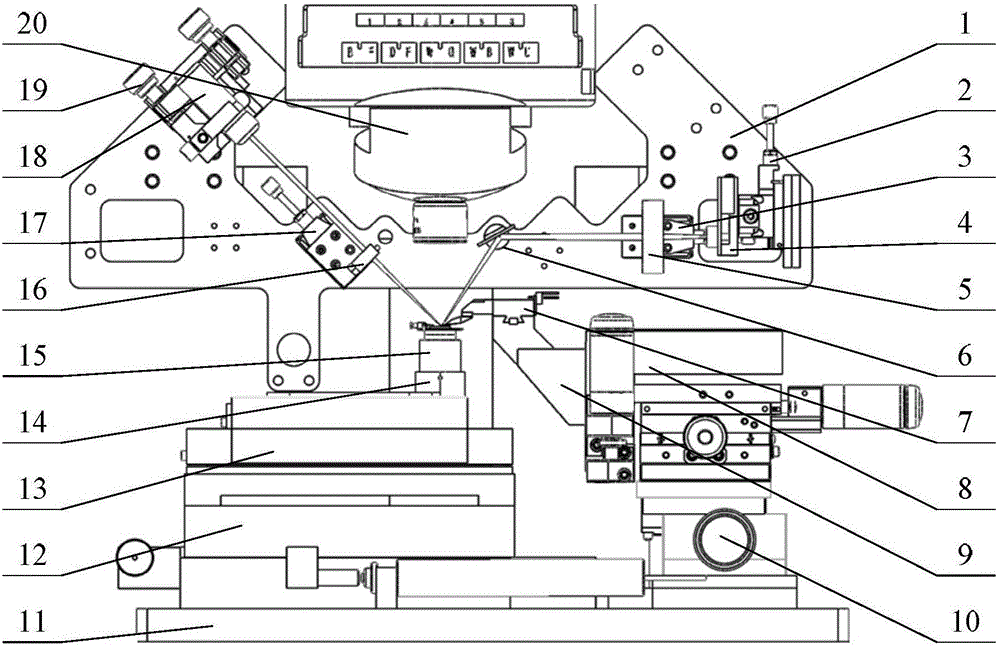

[0039] Specific implementation mode one: combine figure 1 Describe this embodiment, the method for multi-parameter synchronous measurement using a Kelvin probe force microscope described in this embodiment, wherein the Kelvin probe force microscope includes an XY micro-positioning stage 12, an XYZ nano-positioning stage 13, and a Kelvin scanning sample stage 15 , XYZ micron positioning table 8, one-dimensional large-scale adjustment micro-platform 10, probe hand bracket 9, probe hand 7, host computer, DC power supply, arbitrary wave generator, acquisition card, signal generator, phase shifter, lock phase amplifier, four-quadrant position detector, semiconductor laser generator, piezoelectric controller No. 1, piezoelectric controller No. 2 and piezoelectric controller No. 3;

[0040] The Kelvin scanning sample stage 15 is fixed on the XYZ nanopositioning stage 13, and the XYZ nanopositioning stage 13 is fixed on the XY micron positioning stage 12; the probe hand 7 is equipped ...

specific Embodiment approach 2

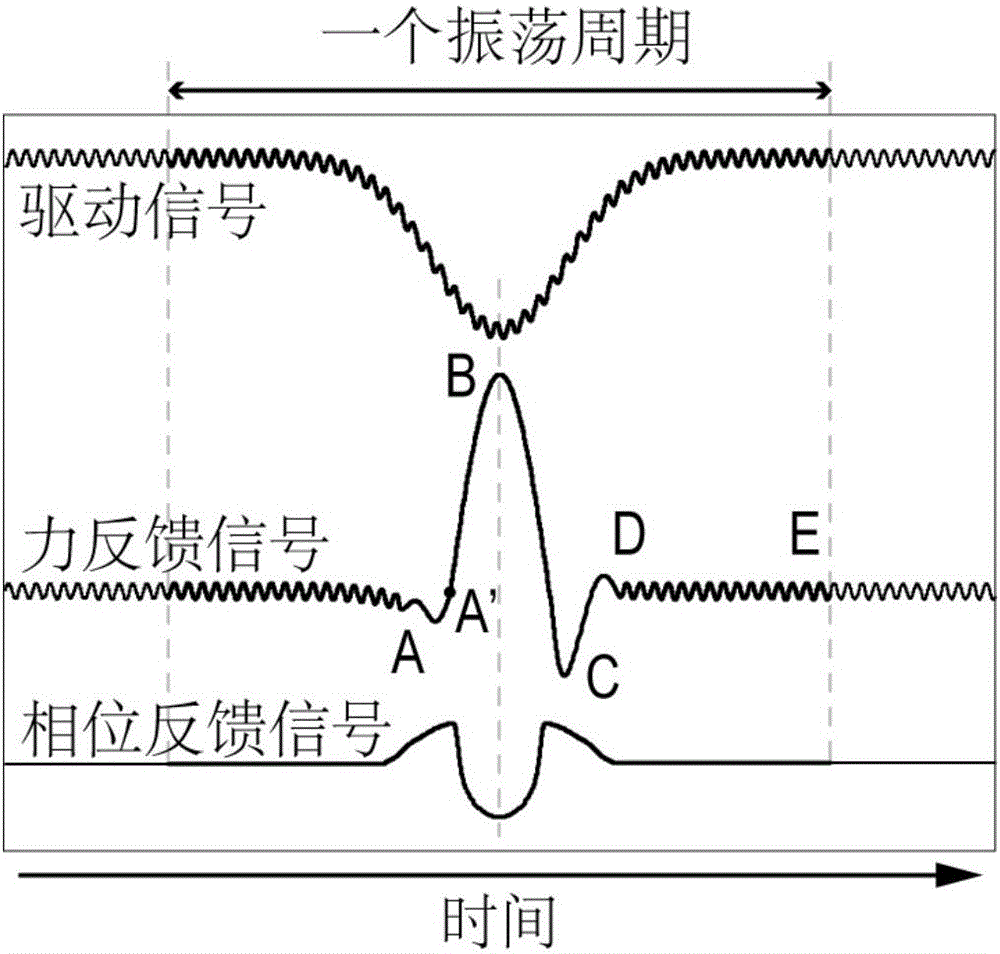

[0084] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. This embodiment is a further limitation of the method described in Embodiment 1. In this embodiment, a measurement module implemented by software is embedded in the host computer, and the measurement module includes the following units:

[0085] Force detection unit: collect the deformation of the conductive probe 7-4 detected by the four-quadrant position detector 4 in real time, and calculate the force between the conductive probe 7-4 and the sample according to the deformation; the force is equal to The product of the deformation amount and the stiffness of the conductive probe 7-4;

[0086] Surface topography and maximum indentation depth measurement unit: Control the Kelvin scanning sample stage 15 to rise through the No. 1 piezoelectric controller, so that the sample is close to the conductive probe 7-4, when the maximum interaction between the conductive probe 7-4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com