Filling type optical cable

A filling type, optical cable technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of optical cable stability, optical performance, bending ability, unsatisfactory optical fiber transmission performance, and high requirements for yarn binding materials. High production efficiency, easy construction and maintenance, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

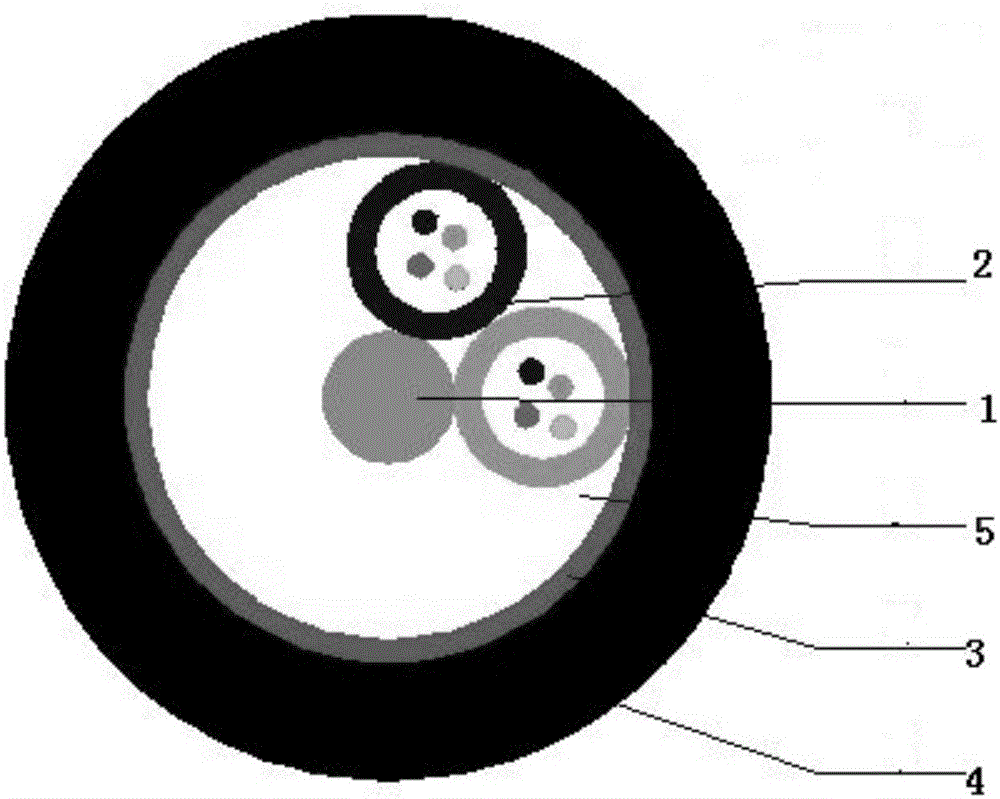

[0024] Such as figure 1 As shown, the injection-filled optical cable 1 includes a cable core, a water-blocking layer 3 and an outer sheath 4 of low-smoke and halogen-free material that are sequentially coated on the outer periphery of the cable core. The cable core includes a steel wire as a strengthening element 1 and a modified polypropylene plastic optical fiber bundle tube 2 arranged on the outer circumference of the steel wire, and the remaining space filled in the water blocking layer 3 after removing the steel wire and the modified polypropylene plastic bundle tube The inner protective layer 5 formed by ethylene-vinyl acetate copolymer material X1, there is no additional sealing between the ethylene-vinyl acetate copolymer material X1 and the steel wire, and between the ethylene-vinyl acetate copolymer material X1 and the modified polypropylene plastic bundle tube . Optical fibers are arranged in the modified polypropylene plastic optical fiber bundle tube, fiber paste...

Embodiment 2

[0032] The injection-filled optical cable 2 includes a cable core, a water-blocking layer and a linear low-density polyethylene outer sheath that are sequentially coated on the outer periphery of the cable core. The cable core includes steel strands as strengthening elements and four polybutylene terephthalate optical fiber bundle tubes twisted around the steel strands, and the steel strands and polyethylene terephthalate are removed by filling in the water-blocking layer. The inner protective layer formed by the ethylene-vinyl acetate copolymer material X2 in the remaining space of the butylene formate optical fiber bundle tube, between the ethylene-vinyl acetate copolymer material X2 and the steel strand, and between the ethylene-vinyl acetate copolymer material X2 and the There is no additional seal between the butylene phthalate fiber optic bundle tubes. The butylene phthalate fiber bundle tube is provided with optical fiber and fiber paste as filling. The stranding pitch...

Embodiment 3

[0040] The injection-filled optical cable 3 includes a cable core, a water-blocking layer, an armor layer, and a medium-density polyethylene outer sheath that are sequentially coated on the outer periphery of the cable core. The cable core includes FRP as a strengthening element and six modified polypropylene plastic optical fiber bundle tubes arranged on the outer periphery of FRP, and ethylene-vinyl acetate copolymer filled in the water-blocking layer to remove the remaining space of FRP and modified polypropylene plastic bundle tubes. The inner protective layer formed by the material X3, and there is no additional seal between the X3 ethylene-vinyl acetate copolymer material and the fiberglass and modified polypropylene plastic bundle tube. The modified polypropylene plastic bundle tube is provided with optical fiber and fiber paste as filling. The stranding pitch of the modified polypropylene plastic bundle tube is 70mm.

[0041] The ethylene-vinyl acetate copolymer mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com