Remote monitoring system and control method of dry cement line debugging based on VPN technology

A remote monitoring system, cement technology, applied in the field of remote control, can solve the problems of a large amount of manpower, financial and material resources, long debugging cycle, huge data, etc., to improve work efficiency, ensure timeliness and accuracy, and reduce bandwidth occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

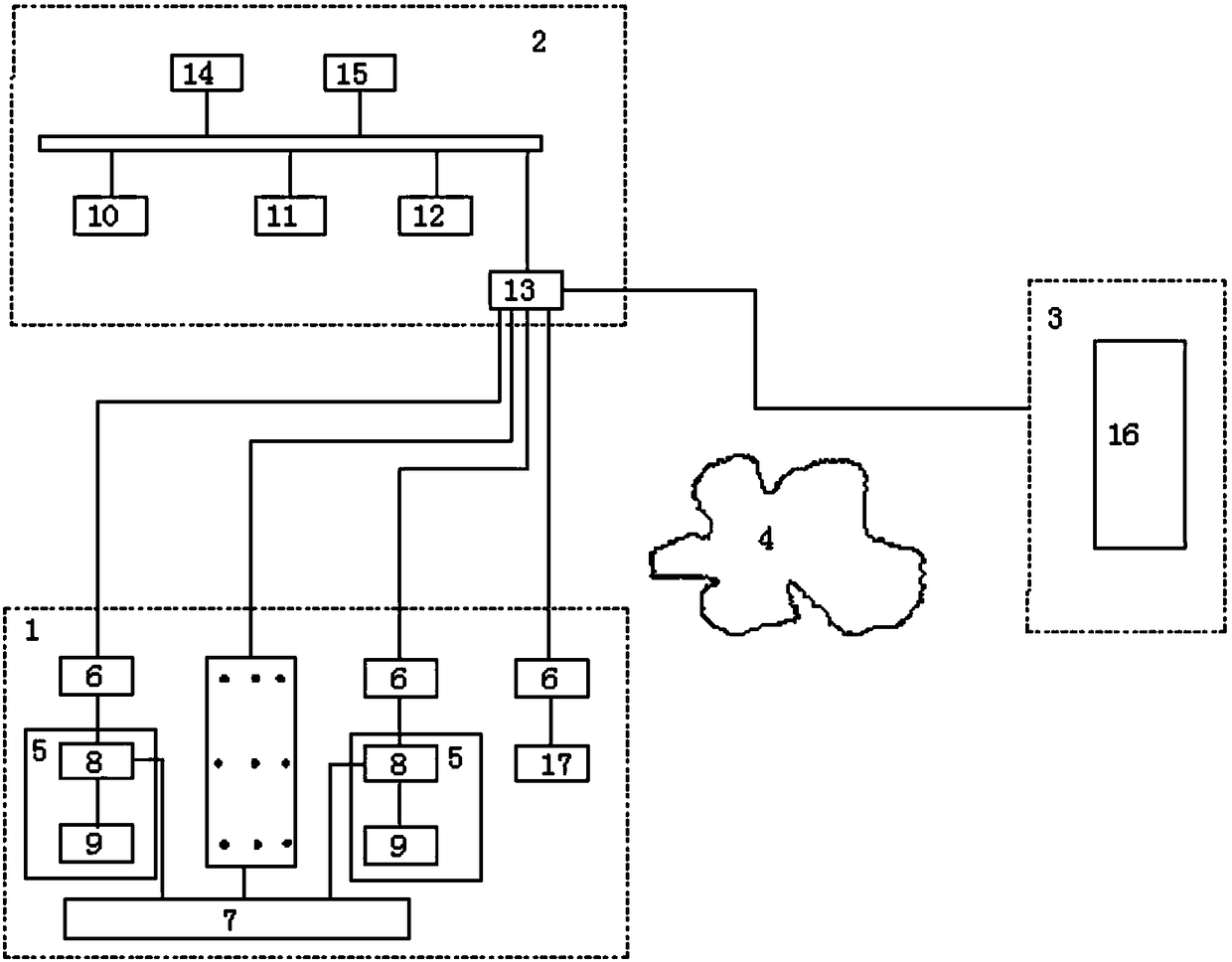

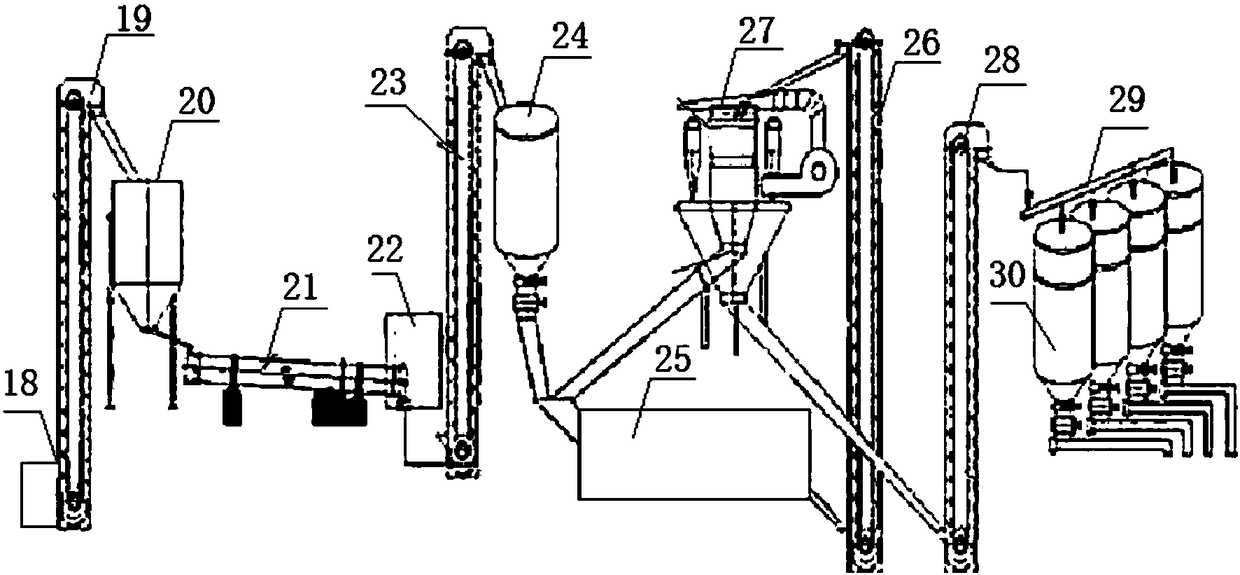

[0039] Embodiment: a kind of remote monitoring system of the dry type cement line debugging based on VPN technology, such as figure 1 and figure 2 As shown, it includes an industrial equipment data acquisition layer 1, an enterprise internal monitoring layer 2 and a remote user terminal monitoring layer 3. The industrial equipment data acquisition layer 1 is connected to the enterprise internal monitoring layer 2 through the Internet 4, and the enterprise internal monitoring layer Layer 2 is connected to the remote user terminal monitoring layer 3 through the Internet 4;

[0040] The industrial equipment data acquisition layer 1 includes the industrial equipment 5 required by the dry cement production line, an industrial computer 6 and a primary alarm unit 7, the industrial equipment 5 is connected to the industrial computer 6, and the primary alarm unit 7 Connect with described industrial equipment 5, each industrial equipment is all provided with PLC controller 8, data col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com