Multi-scale image contrast enhancement method for pipeline welding seam detection

A welding seam detection and image comparison technology is applied in the field of multi-scale image contrast enhancement for pipeline weld inspection, which can solve problems such as dark X-ray digital imaging, and achieve the effects of improving quality, improving detection accuracy, and improving local clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

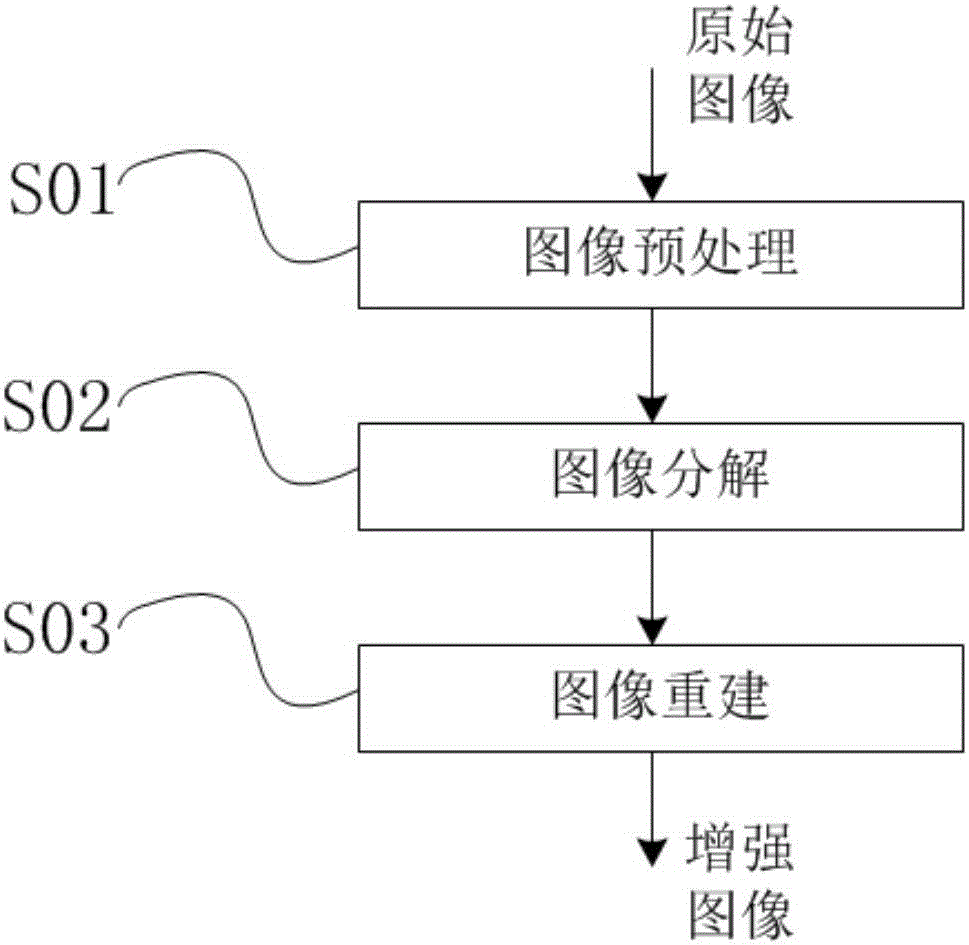

[0040] The original X-ray image of the pipeline weld is attached Figure 11 As shown, the multi-scale image contrast enhancement method of the present invention is used for processing, and the steps are as follows figure 1 As shown, the specific description is as follows:

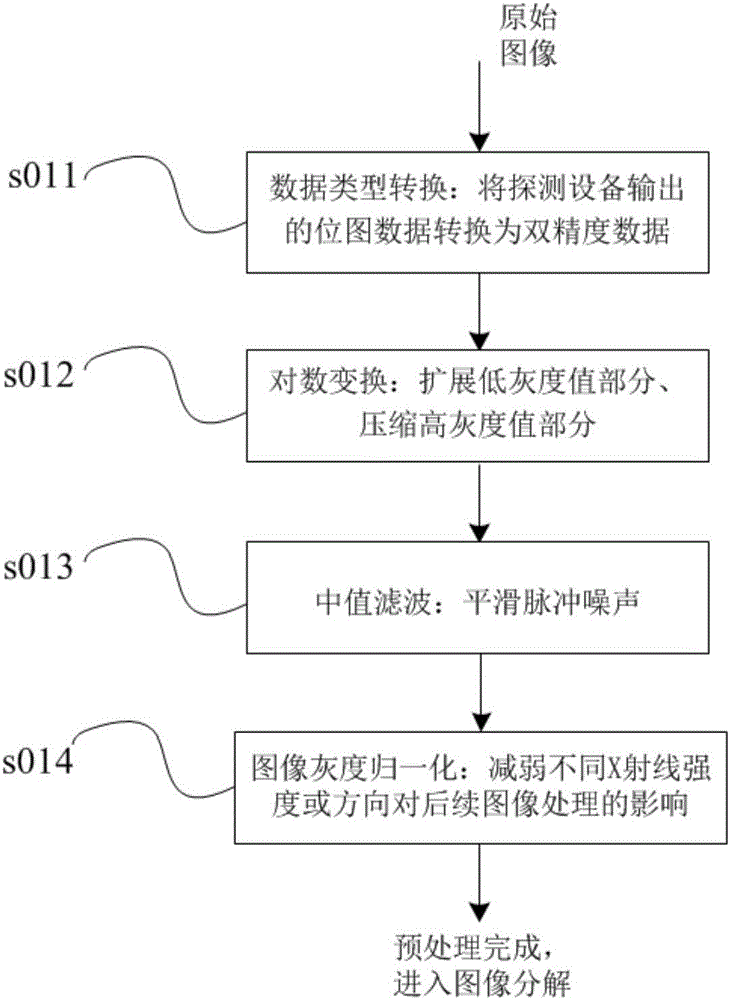

[0041] S01, image preprocessing is performed on the original image, the steps are as follows figure 2 As shown, specifically:

[0042] s011. Data type conversion: convert the bitmap data of the original image into double-precision data;

[0043] s012. Logarithmic transformation: expand the low gray value part and compress the high gray value part to achieve the purpose of emphasizing the low gray value part;

[0044] s013. Median filtering: smoothing impulse noise, such as abnormal pixels on a flat panel detector;

[0045] s014. Image grayscale normalization: weaken the influence of different X-ray intensities or directions on subsequent image processing;

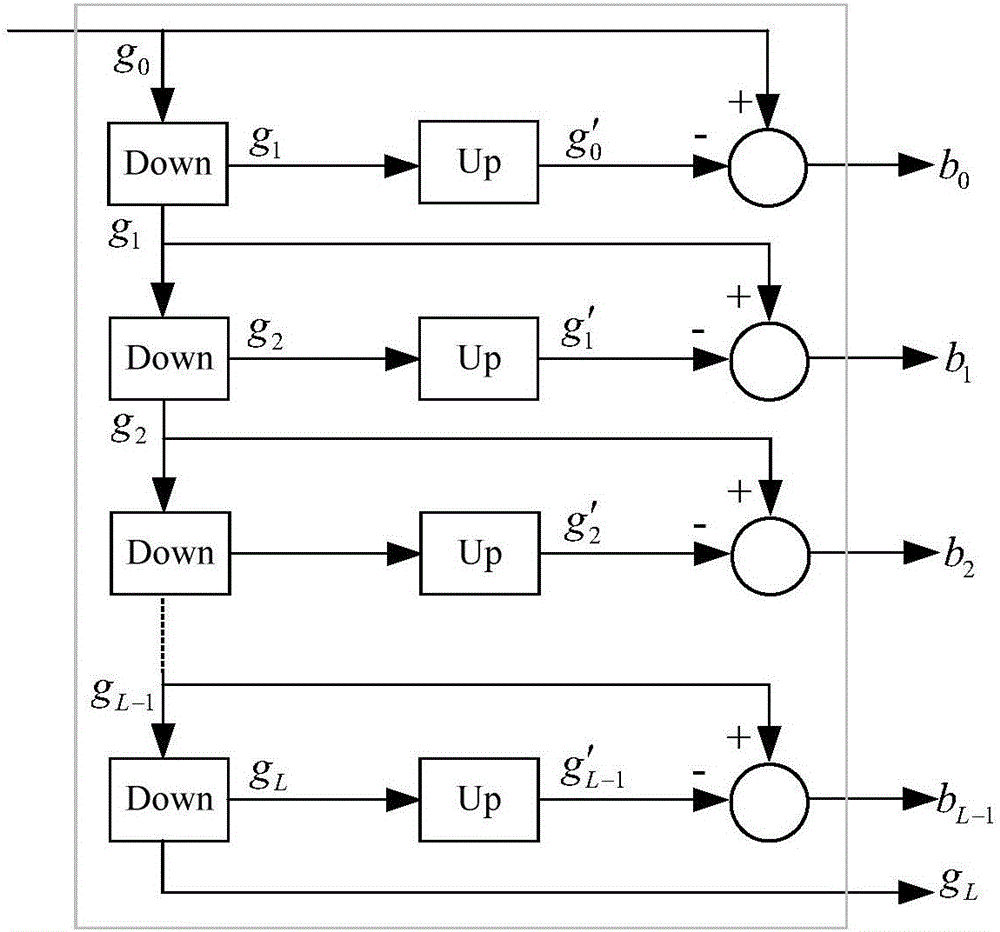

[0046] S02. Decompose the preprocessed image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com