Preparation method of high-performance permanent magnet and vacuum undulator magnetic structure with high-performance permanent magnet

A permanent magnet, high-performance technology, applied in the manufacture of permanent magnets, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of unstable heat treatment process, unoptimized permanent magnet orientation thickness, and consistent intrinsic coercive force of permanent magnets Sexuality is not good and other problems, to achieve the effect of Hcj consistency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

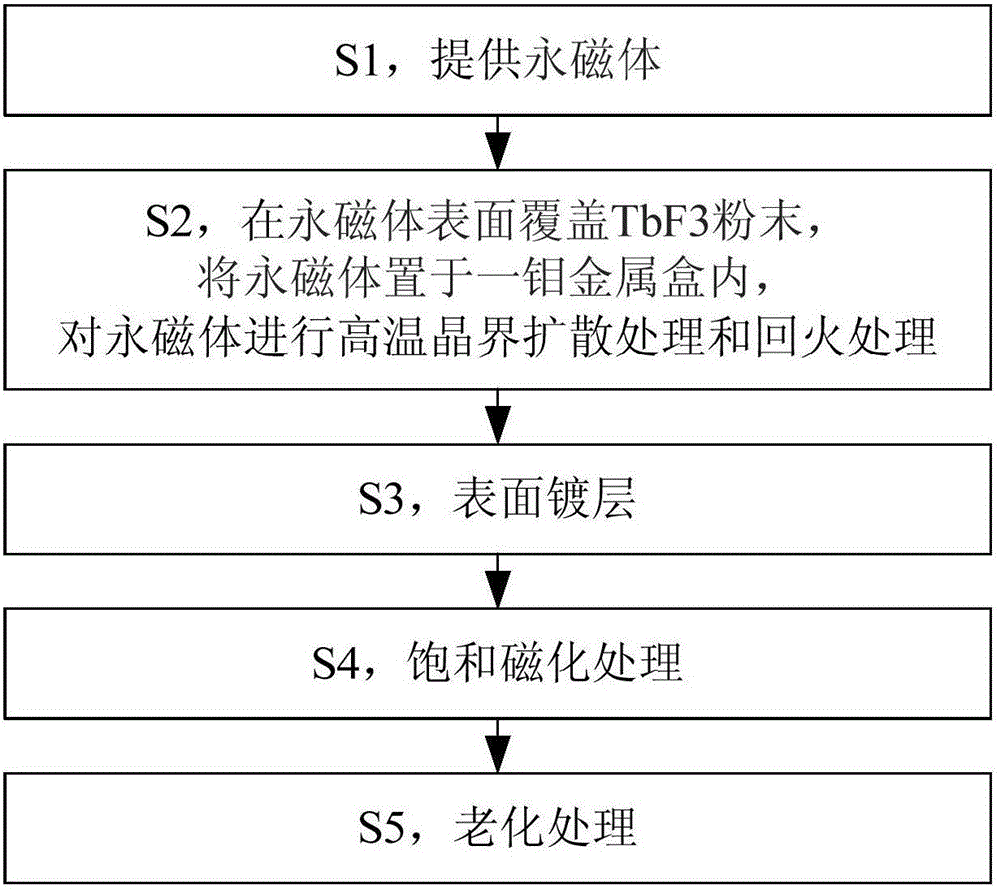

[0046] Below, according to the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

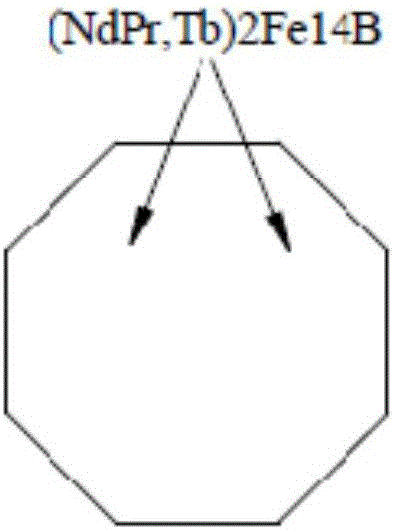

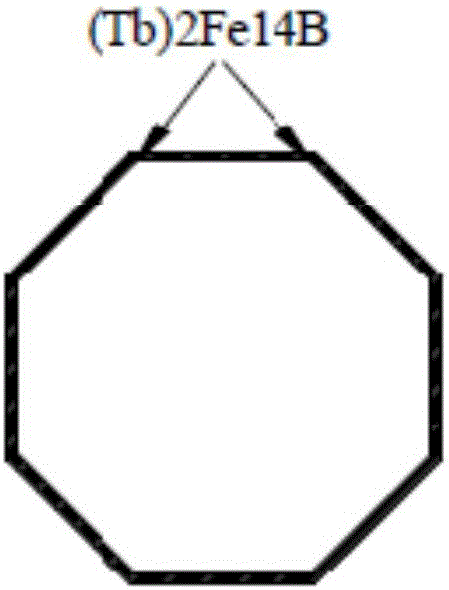

[0047] The high-performance permanent magnet preparation method of the present invention is used to greatly improve the intrinsic coercive force of the permanent magnet on the basis of conventional anisotropic sintered NdFeB, PrFeB or NdPrFeB permanent magnets. The specific process flow Such as figure 2 shown, including the following steps:

[0048] S1, providing anisotropic sintered NdFeB, PrFeB or NdPrFeB permanent magnets with a thickness of 2.0mm-2.5mm in the magnetization direction.

[0049] S2, through processes such as surface coating, the surface of the permanent magnet is covered with a layer of TbF3 powder (the powder particle size is 1-7 microns); then the permanent magnet is placed in a molybdenum metal box, because molybdenum metal can be com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com