Dual-polarized leakage waveguide

A leaky waveguide and dual-polarization technology, applied to waveguides, waveguide-type devices, circuits, etc., can solve the problems of affecting system engineering cost, limited laying space, and increased maintenance costs, so as to improve system channel capacity and field strength drop The effect of reducing and reducing the fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

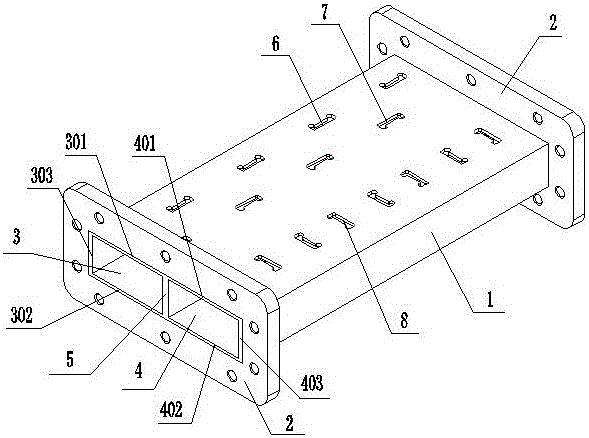

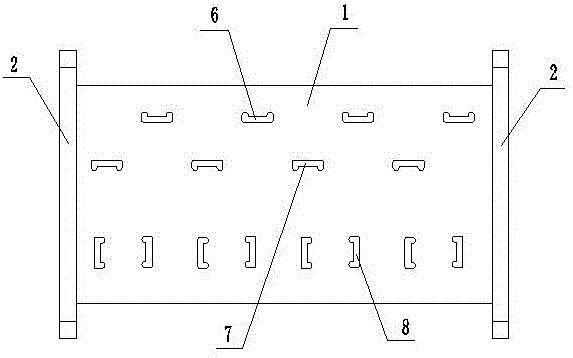

[0052] like figure 1 and figure 2 As shown, the dual-polarization leaky waveguide of the present invention includes a rectangular waveguide 1 and a pair of rectangular flanges 2, and the rectangular flanges 2 are respectively welded to the outer surfaces of the two ends of the rectangular waveguide 1 by argon arc welding or brazing process. As a whole, multiple rectangular waveguides 1 of the same or different lengths are connected by rectangular flanges 2 and fastening bolts to form the required length, and are laid on the inside or outside of the track for vehicle-to-ground wireless signal transmission.

[0053] The rectangular waveguide 1 of the present invention is made of high-conductivity copper, aluminum or aluminum alloy, and is formed by one-time drawing or extrusion process. The rectangular waveguide 1 includes two rectangular cavities arranged in parallel along the length direction, respectively The first waveguide cavity 3 and the second waveguide cavity 4, the f...

Embodiment 2

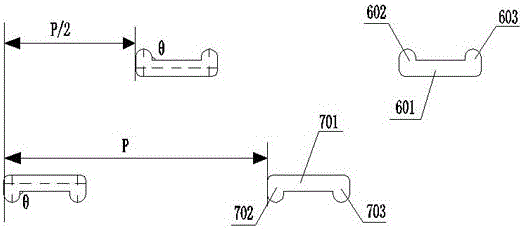

[0061] like Figure 5 and Image 6 As shown, the structure of the rectangular waveguide 1 and the rectangular flange 2 of this embodiment is exactly the same as that of the first embodiment, so the same parts use the numbers in the first embodiment, the difference lies in the generation of vertically polarized waves and horizontally polarized waves The shape of the leaky gap for the wave.

[0062] The first upper wide surface 301 of the first waveguide cavity 3 of the present invention is provided with leakage slits that generate vertically polarized waves, including a first leakage slit 9 and a second leakage slit 10, each of which includes a slit along the waveguide. A plurality of slits arranged at equal intervals along the length direction. The vertical distance between the first leakage slit 9 and the front narrow surface 303 is greater than the thickness of the front narrow surface 303, the vertical distance between the second leakage slit 10 and the first leakage slit...

Embodiment 3

[0069] like Figure 9 and Figure 10 As shown, the structure of the rectangular waveguide 1 and the rectangular flange 2 of this embodiment is exactly the same as that of the first embodiment, so the same parts use the numbers in the first embodiment, the difference lies in the generation of vertically polarized waves and horizontally polarized waves The shape of the leaky gap for the wave.

[0070] The first upper wide surface 301 of the first waveguide cavity 3 of the present invention is provided with leakage slits that generate vertically polarized waves, including the first leakage slit 12-1 and the second leakage slit 12-2, each leakage slit Both include a plurality of slots arranged at equal intervals along the length direction of the waveguide. The vertical distance between the first drainage slit 12-1 and the front narrow surface 303 is greater than the thickness of the front narrow surface 303, and the vertical distance between the second drainage slit 12-2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com