Multifunctional structure cable for spacecraft and manufacturing method of multifunctional structure cable

A multi-functional, spacecraft technology, applied in the direction of electrical components, can solve problems such as cumbersome assembly procedures, reduce system reliability, and signal interference, and achieve the goals of improving flexibility and reliability, increasing payload ratio, and eliminating negative volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Another aspect of the present invention also provides a preparation method for the above cable, comprising the following steps:

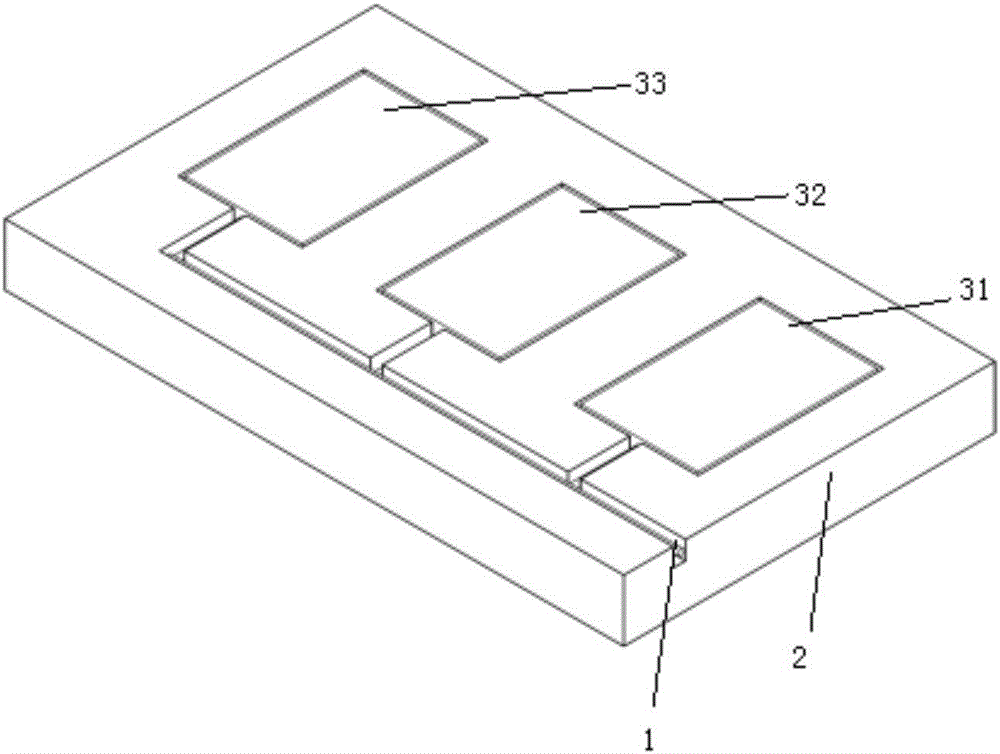

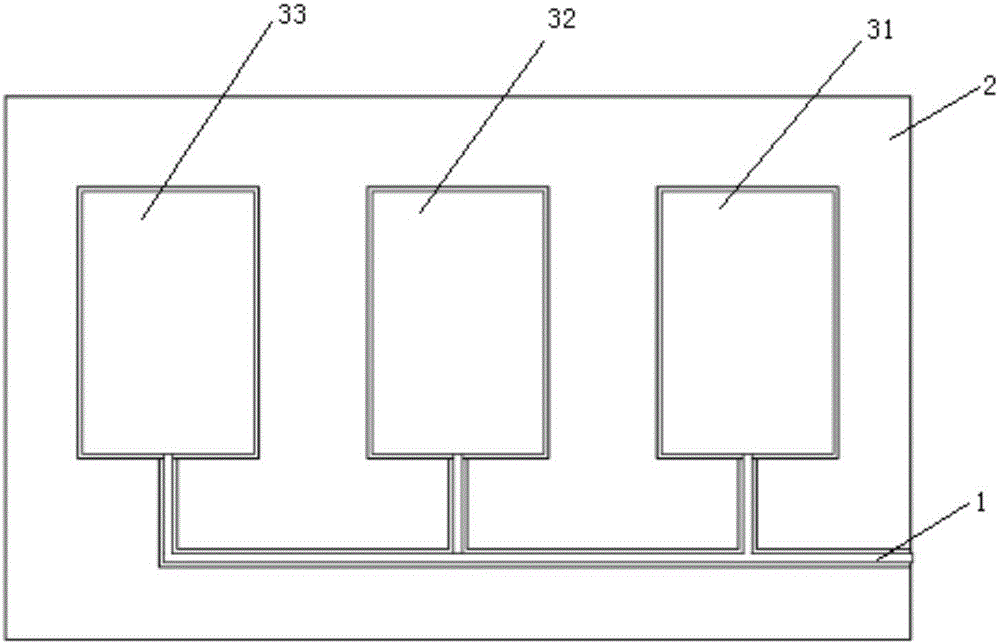

[0045] 1) Open cable laying grooves and device installation grooves on the substrate according to the optimized design of the circuit;

[0046]2) Embed the cable in the electrical laying groove, reserve the cable outlet at the device installation groove, and reserve the cable inlet on one side of the substrate;

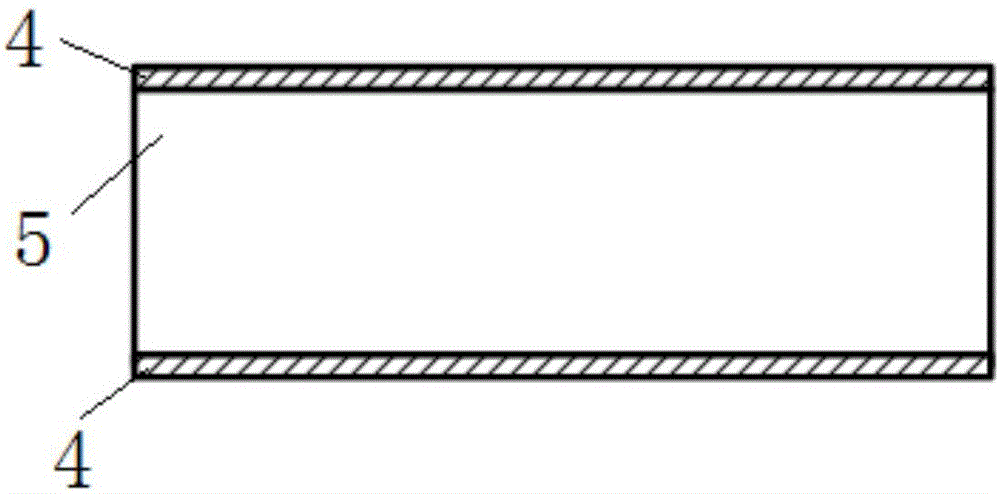

[0047] 3) GD414 silicone rubber is filled in the cable laying groove, the substrate is encapsulated with a packaging plate, and the substrate is cured with silica gel to obtain a multifunctional structural cable for spacecraft.

[0048] The optimized design here refers to the cable layout design to reduce the crossover of cables. It can be carried out according to the existing method.

[0049] Preferably, the conditions for curing the silica gel are as follows: the heating rate is 3° C. / min to 5° C. / min, and the temperature is rais...

Embodiment 1

[0059] The specific method of cable laying is as follows: use a cutter to open a groove with a certain width and depth on the PMI foam sandwich composite structure (the size is 1mm to 2mm larger than the diameter of the cable), and after the cable is embedded, fill it with GD414 silicone rubber for fixing. , put the PMI foam sandwich composite structure into a large temperature control box to cure the silicone rubber. During the curing process, the temperature rise rate was controlled at 3°C / min, and the maximum temperature was controlled at 65°C for 20 hours.

Embodiment 2

[0061] The specific method of cable laying is as follows: use a cutter to open a groove with a certain width and depth on the PMI foam sandwich composite structure (the size is 1mm to 2mm larger than the diameter of the cable), and after the cable is embedded, fill it with GD414 silicone rubber for fixing. , put the PMI foam sandwich composite structure into a large temperature control box to cure the silicone rubber. During the curing process, the temperature rise rate was controlled at 5°C / min, and the maximum temperature was controlled at 75°C for 10 hours.

[0062] Finally, for the matrix obtained in Example 1 or 2, the overall structure is packaged with a carbon fiber composite material panel, so as to realize the space between spacecraft cables (electric wires, data lines, signal lines, etc.) ), and at the same time between the PMI foam sandwich composite structure and the PMI foam sandwich composite structure, a flexible flat matrix cable connector is used to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com