Electrical system of graphene microwave puffing equipment

A technology of microwave puffing and electrical systems, applied in microwave heating, electrical components, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve problems such as short circuits of electrical equipment, and achieve the goal of reducing work intensity and loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

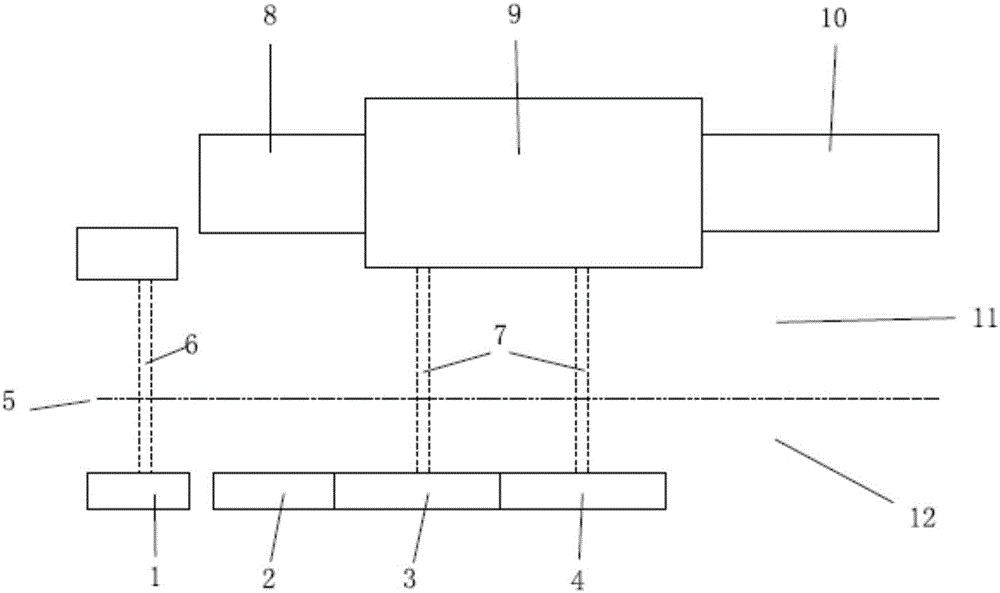

[0022] figure 1 It shows the overall schematic diagram of the electrical system of a kind of graphene microwave puffing equipment provided by the present invention, the system includes a production unit 11 and a control unit 12, a partition wall 5 is arranged between the production unit 11 and the control unit 12, The production unit 11 includes: a microwave equipment main cavity 9, a first suppressor 8 connected to one end of the microwave equipment main cavity 9, and a second suppressor 10 connected to the other end of the microwave equipment main cavity 9 , realizing the isolation of the production unit 11 and the control unit 12, using the partition wall 5 to separate the space into a production workshop and a control room, the main microwave equipment is located in the production workshop, control electrical cabinet 1, power electrical cabinet 2, microwave power supply Located in the control room and separated from the production workshop full of graphite dust; the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com