A UV curable coating

A technology of curing coatings and ultraviolet light, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of weak weather resistance, shortened substrate protection, aging of cured film layers, etc., to solve the problem of short service life , Good effect of chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Polyurethane acrylate resin CN984 25 parts,

[0031] Active diluent TMPTA 8 parts,

[0032] Active diluent TPGDA 4 parts,

[0033] Active diluent HDDA 8 parts,

[0034] Photoinitiator Irgacure 184 2 parts,

[0035] Defoamer BYK020 0.1 parts,

[0036] Leveling agent BYK307 0.08 parts,

[0037] Nano zinc oxide 1.5 parts,

[0038] Nano-tin antimony oxide 1.0 parts,

[0039] Stir and mix 25 parts of prepolymer resin CN984, 8 parts of reactive diluent TMPTA, 4 parts of TPGDA, 8 parts of HDDA, 2 parts of photoinitiator Irgacure 184, 0.08 parts of leveling agent BYK307 and 0.1 part of defoamer BYK020 , adding 1.5 parts of nano-zinc oxide and 1.0 part of nano-tin antimony oxide and fully stirring and mixing uniformly to obtain a UV-curable coating.

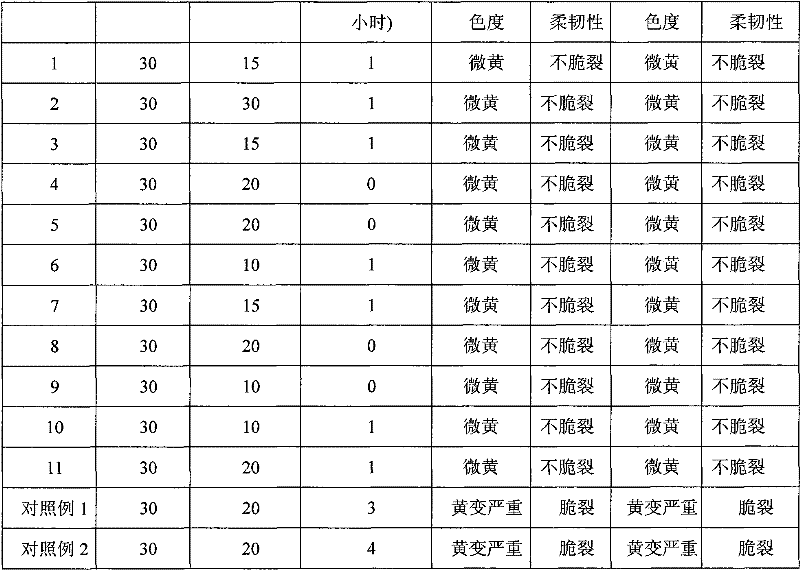

[0040] The paint obtained above was coated on PET by a dip coating method, leveled at 80°C under infrared rays, and cured by irradiation with a 1kw high-pressure mercury lamp to obtain a UV-cured film. Measure its performan...

Embodiment 2

[0042] Polyurethane acrylate resin CN9001 30 parts,

[0043] Active diluent TMPTA 6 parts,

[0044] Active diluent TPGDA 3 parts,

[0045] Active diluent HDDA 6 parts,

[0046] Photoinitiator Irgacure 184 1 part,

[0047] Defoamer BYK020 0.1 parts,

[0048] Leveling agent BYK307 0.08 parts,

[0049] 1.5 parts of nano-titanium oxide,

[0050] Nano-tin antimony oxide 1.0 parts,

[0051] Stir and mix 30 parts of prepolymer resin CN9001, 6 parts of reactive diluent TMPTA, 3 parts of TPGDA, 6 parts of HDDA, 1 part of photoinitiator Irgacure 184, 0.08 parts of leveling agent BYK307 and 0.1 part of defoamer BYK020 , adding 1.5 parts of nano-titanium oxide and 1.0 part of nano-tin antimony oxide and fully stirring and mixing uniformly to obtain a UV-curable coating.

[0052] The paint obtained above was coated on PET by an extrusion coating method, leveled at 80° C. under infrared rays, and cured by irradiation with a 1 kw high-pressure mercury lamp to obtain a UV-cured film. ...

Embodiment 3

[0054] Polyurethane acrylate resin CN9004 35 parts,

[0055] 4 parts of reactive diluent TMPTA,

[0056] Active diluent TPGDA 2 parts,

[0057] Active diluent HDDA 4 parts,

[0058] Photoinitiator Irgacure 1173 2.5 parts,

[0059] 1.0 parts of nano-titanium oxide,

[0060] Nano-tin antimony oxide 1.0 parts,

[0061] 35 parts of prepolymer resin CN9004, 4 parts of reactive diluent PETA, 2 parts of TPGDA, 4 parts of HDDA, 2.5 parts of photoinitiator Irgacure 1173, 1.0 parts of nano-titanium oxide, and 1.0 part of nano-tin antimony oxide were fully stirred and mixed evenly to obtain UV curable coatings.

[0062] The paint obtained above was coated on PET by an extrusion coating method, leveled at 80° C. under infrared rays, and cured by irradiation with a 1 kw high-pressure mercury lamp to obtain a UV-cured film. Measure its performance, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com