Electromagnet-friction piezoelectric composite energy harvester

An energy harvester and composite technology, which is applied in the directions of triboelectric generators, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problems of low harvesting efficiency and achieve energy harvesting efficiency High, increased output, convenient design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

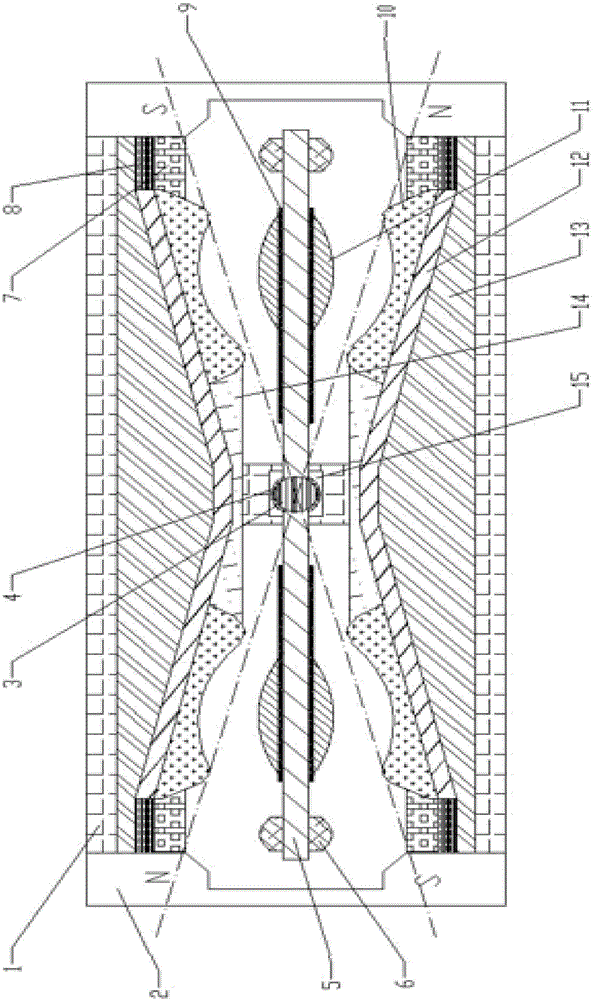

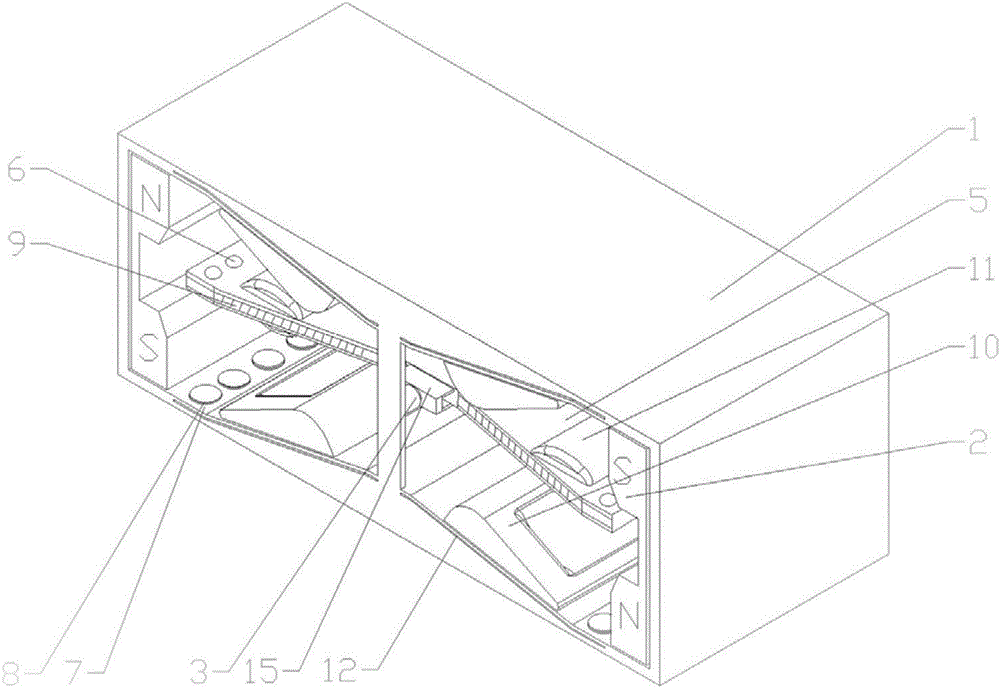

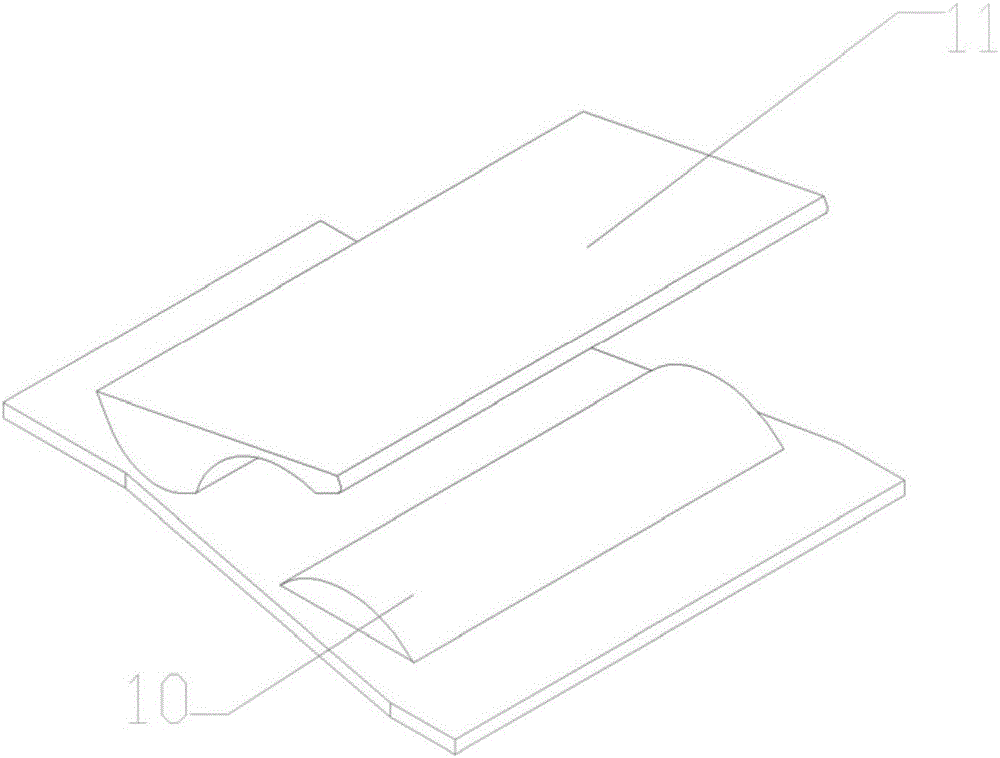

[0022] The two sides of the collector housing 1 are symmetrically equipped with "gate"-shaped permanent magnets 2 with opposite magnetic poles. The rotating shaft 3 is connected to the housing 1 through the bearing 4. The concave cantilever beam 5 is fixedly connected to the rotating shaft 3. The two ends of the cantilever beam 5 are respectively fixedly connected to the hemispherical mass block 6, and the piezoelectric ceramic 8 covered with the buffer layer 7 corresponds to the mass block 6 one by one, and is installed inside the housing 1. A coil 9 is wound on the cantilever beam 5, and the coil 9 9 is attached with a second friction layer 11, and the corresponding positions between the second friction layer 11 and the housing 1 are the first friction layer 10, the flexible piezoelectric material 12 and the insulating filling layer 13, and the collected energy passes through the first electrode Layer 14 and the second electrode layer 15 are externally connected to the line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com