Pollinator suitable for high branch pollination

A pollinator and high branch technology, which is applied in the fields of application, plant genetic improvement, botanical equipment and methods, etc., can solve the problems of insecure pollination rate, difficult pollen ejection, and difficult climbing operation, etc., so as to improve pollination. Efficiency, light weight and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

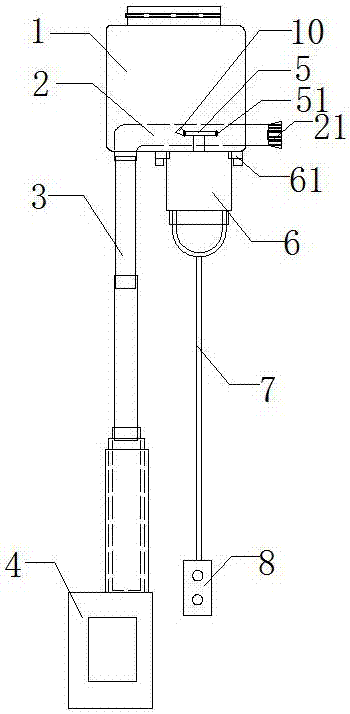

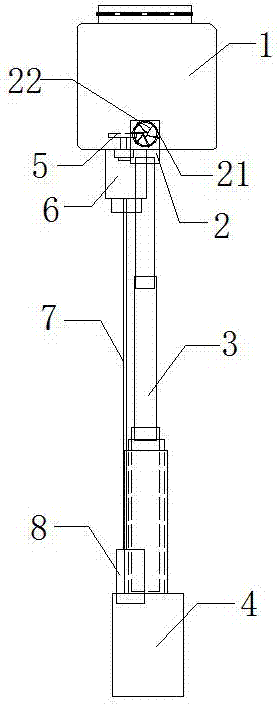

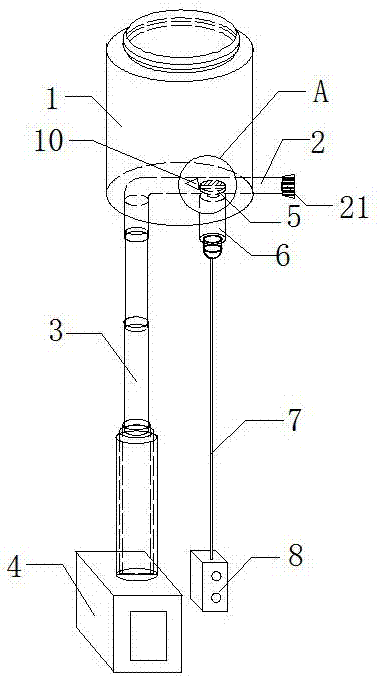

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-5 As shown in , a pollinator suitable for high-branch pollination includes a powder storage tank 1, and the powder storage tank 1 is provided with an L-shaped tube 2 that runs through the bottom surface and the side of the powder storage tank 1, and the bottom of the L-shaped tube 2 communicates with a telescopic The airflow lifting rod 3 is connected with the electric blower 4 below the airflow lifting rod 3; the L-shaped pipe 2 side is provided with an air spout 21, where the air spout is a trumpet shape opened outwards, and the L-shaped pipe 2 wall side is provided with a rectangular cavity The slot 23 is provided with a horizontally arranged wheel piece 5 at the rectangular empty slot 23, the bottom of the wheel piece 5 is driven by a motor 6 located at the bottom of the powder storage tank 1, and one side of the wheel piece 5 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com