Precision machine-processed processing method of Mingzhouxianming tea

A processing method and mechanism technology, applied in the field of precise mechanism Mingzhou Xianming processing, can solve problems such as unfavorable Mingzhou Xianming brand building and market construction, unstable processing, uneven batch quality, etc. The effect of chemical production, stable product quality and high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

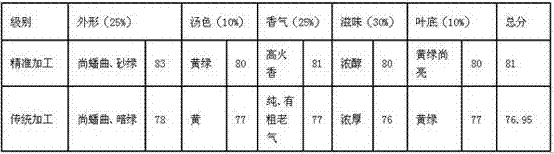

Embodiment 1

[0026] A kind of fresh leaf raw material used for the processing of high-quality green tea with a precision mechanism curling shape is: 160 kg of tea fresh leaves based on one bud and two leaves, including the following steps:

[0027] 1) Fresh leaves are spread on multi-layer stainless steel screens (spreading thickness ≤ 4cm), placed in the constant temperature and humidity intelligent greening room produced by Ningbo Yaojiangyuan Machinery Co., Ltd., set the temperature at 20°C, humidity at 65°, and the processing time is 4.5 h±0.5 h, until the moisture content of fresh leaves is about 68%;

[0028] 2) Use the 80-type electromagnetic roller degreening machine produced by Ningbo Yaojiangyuan Machinery Co., Ltd. to complete the green leaves obtained in step 1). The time-consuming control of finishing is 107s±3s, until the water content is 58%;

[0029] 3) Soften the tea leaves obtained in step 2) with the 20-type dampening machine (mesh belt type) produced by Ningbo Yaojiang...

Embodiment 2

[0041] A kind of fresh leaf raw material used for the processing of high-quality green tea with a precision mechanism curling shape is: 200 kg of tea fresh leaves based on one bud and three leaves, including the following steps:

[0042] 1) Fresh leaves are spread on multi-layer stainless steel screens (spreading thickness ≤ 4cm), placed in the constant temperature and humidity intelligent greening room produced by Ningbo Yaojiangyuan Machinery Co., Ltd., set the temperature at 20°C, humidity at 65°, and the processing time at 4.0 h±0.5 h, until the moisture content of fresh leaves is 68%;

[0043] 2) Use the 80-type electromagnetic drum fixer produced by Ningbo Yaojiangyuan Machinery Co., Ltd. to fix the green leaves obtained in step 1). The finishing time is controlled to be 105s±3 s, and the moisture content is 58%;

[0044]3) Soften the tea leaves obtained in step 2) with the 20-type dampening machine (mesh belt type) produced by Ningbo Yaojiangyuan Machinery Co., Ltd., s...

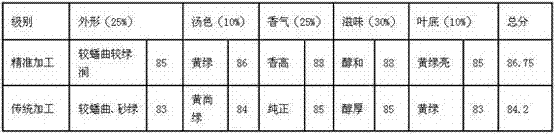

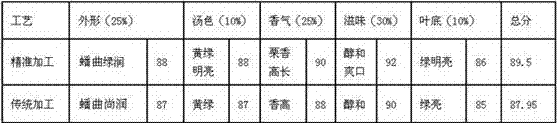

Embodiment 3

[0056] A kind of raw material of fresh leaves used for the processing of high-quality green tea with precise mechanism curling is: mainly one bud with four leaves and the same tenderness pair of clipped leaves, 200kg of a single fresh leaf, including the following steps:

[0057] 1) Fresh leaves are spread on multi-layer stainless steel screens (spreading thickness ≤ 4cm), placed in the constant temperature and humidity intelligent greening room produced by Ningbo Yaojiangyuan Machinery Co., Ltd., set the temperature at 22°C, humidity at 67°, and the processing time is 3.5 h±0.5 h, until the moisture content of fresh leaves is 68%;

[0058] 2) Use the 80-type electromagnetic drum fixer produced by Ningbo Yaojiangyuan Machinery Co., Ltd. to fix the green leaves obtained in step 1). The finishing time is controlled to be 103s±3s, and the moisture content is 58%;

[0059] 3) Soften the tea leaves obtained in step 2) with the 20-type dampening machine (mesh belt type) produced by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com