Flavor bead jelly and making method thereof

A technology of popping beads and jelly, applied in the direction of food science, etc., can solve problems such as decline and lack of novelty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

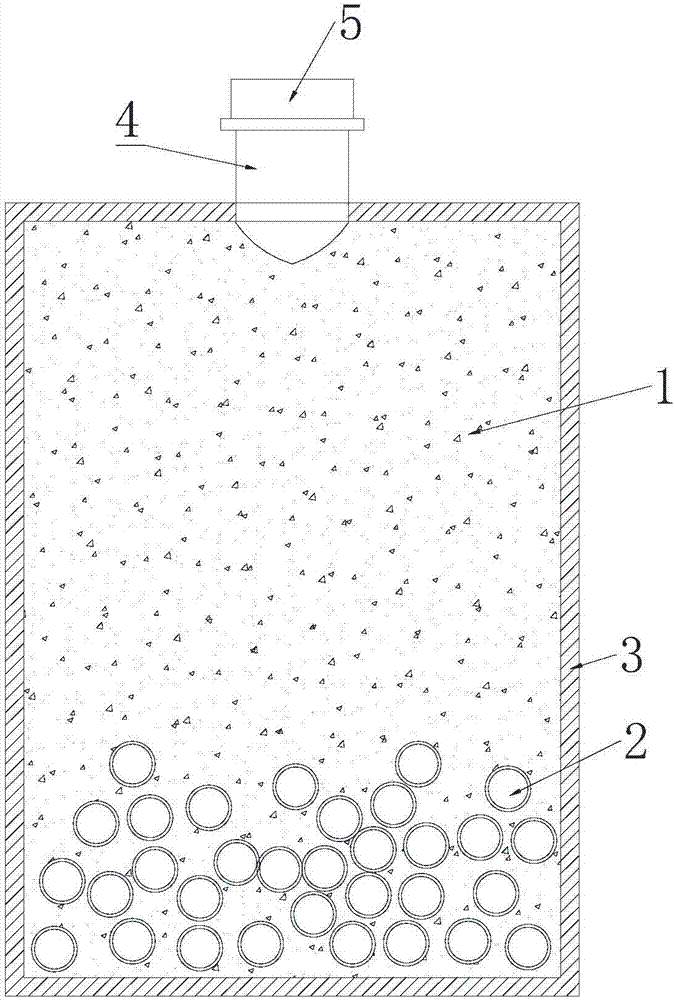

[0060] The following is the preparation method of flavor popping pearl jelly, including the following steps:

[0061] A, prepare quick-fried beads;

[0062] B, preparing jelly products;

[0063] B1. Take the white granulated sugar and jelly according to the formula, put them into the container and stir evenly, then weigh the corresponding proportion of water and put them into the blender and stir evenly;

[0064] B2. Pour the stirred raw materials into the cooking tank, add sodium citrate, citric acid, malic acid, and potassium sorbate, heat up to 94-96°C, cook for 15-30 minutes, and keep stirring during the cooking process. And add the corresponding amount of fructose;

[0065] B3. The feed liquid prepared in step B2 is filtered through a 100-400 mesh filter to obtain a jelly liquid;

[0066] B4. Filling and adding prepared popping beads;

[0067] B5. Fill jelly liquid, sterilize, cool and solidify, and pack.

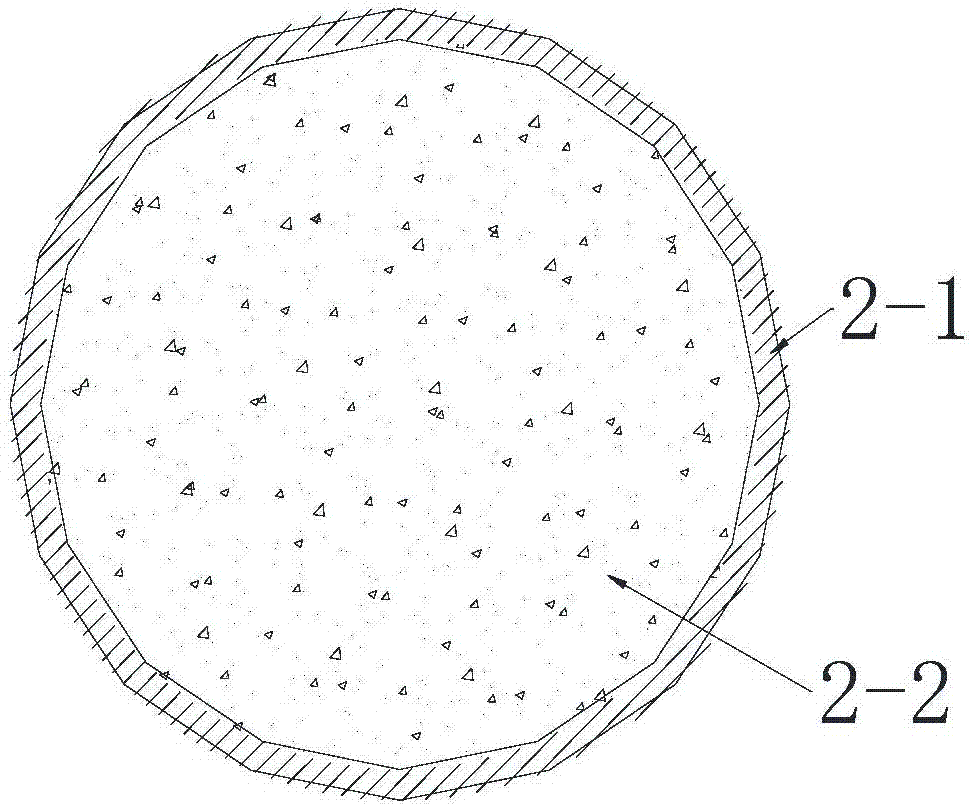

[0068] In said step A, the specific production steps of popp...

Embodiment 1

[0080] In the present embodiment, the raw materials of the flavored pop-ball jelly include 60 parts by weight of pop-ball granules, 20 parts of white sugar, 67 parts of fructose, 4 parts of jelly powder, 0.1 part of potassium sorbate, 0.2 part of sodium citrate, and 0.3 parts of citric acid. part, 0.2 part of malic acid, and 350 parts of water. Among them, the raw materials of jelly powder include 23% gellan gum, 20% potassium chloride, 16% carrageenan, 15% konjac flour, 12% locust bean gum, 4% potassium citrate, 4% non-dairy creamer, Maltodextrin 3%, glucose 3%.

[0081] In this embodiment, the popcorn added to the jelly is rich in the flavor of fermented apple juice. The specific processing steps of the popcorn are as follows:

[0082] (1) Pour 58g of purified water, 30g of white sugar, 5g of fermented apple juice, 3g of calcium lactate, 1g of potassium sorbate, and 3g of xanthan gum into the blender at room temperature, and form a center solution after completely dissolvin...

Embodiment 2

[0090] In this embodiment, the raw materials of the flavored pop-ball jelly include 70 parts by weight of pop-ball granules, 26 parts of white sugar, 70 parts of fructose, 4 parts of jelly powder, 0.05 parts of potassium sorbate, 0.3 parts of sodium citrate, and 0.3 parts of citric acid , 0.2 parts of malic acid, 400 parts of water. The raw materials of jelly powder include 27% gellan gum, 18% potassium chloride, 20% carrageenan, 15% konjac flour, 13% locust bean gum, 3% potassium citrate, 2% non-dairy creamer and malt paste by weight percentage Refined 1%, glucose 1%.

[0091] The quick-fried pearls added to the jelly in this embodiment are rich in coffee-flavored quick-fried pearls, and the specific processing steps of the quick-fried pearls are as follows:

[0092] (1) Pour 67.3g of purified water, 25g of white sugar, 2.5g of coffee extract, 1.2g of calcium lactate, 1g of potassium sorbate, and 3g of xanthan gum into the mixer at room temperature, and dissolve them complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com