Apparatus and method for processing inorganic coating agent

A coating agent and inorganic technology, which is applied in the field of processing inorganic coating agents, can solve the problems of unstable performance of titanium dioxide, affect the production cycle of titanium dioxide, and affect the weather resistance of products, so as to shorten the dilution time and improve market competition force, improve the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

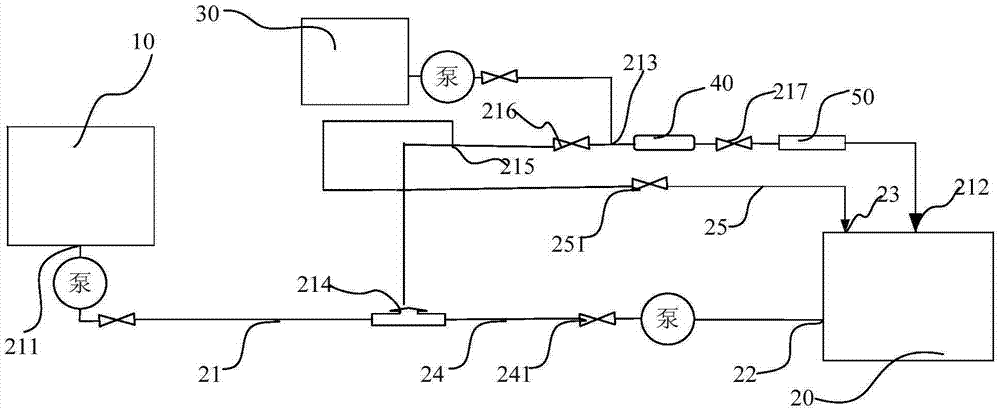

[0035] According to another aspect of the present invention, the present invention proposes a method for treating inorganic coating agents, which uses the aforementioned device for treating inorganic coating agents. According to a specific embodiment of the present invention, the method includes: transporting the water glass in the water glass storage tank and the desalted water in the desalted water storage tank to the first pipeline; making the water glass and the desalted water pass through the density after mixing in the mixer After the instrument monitors the density, it enters the water glass dilution tank. In this way, the dilution can be completed in the mixer, and the automatic detection by the density meter can not only improve the uniformity of dilution, but also improve the accuracy of dilution, thereby effectively avoiding uneven dilution that will affect the organic coating of titanium dioxide and affect the weather resistance of the product. Properties such as sex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com