Porous lamellar-structured titanic acid particle and preparation method thereof

A layered structure and porous layer technology, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve problems such as complex process, difficult control, unsuitable for mass production, etc., to achieve The requirements for experimental equipment are simple, the photocatalytic performance is improved, and the effect of improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

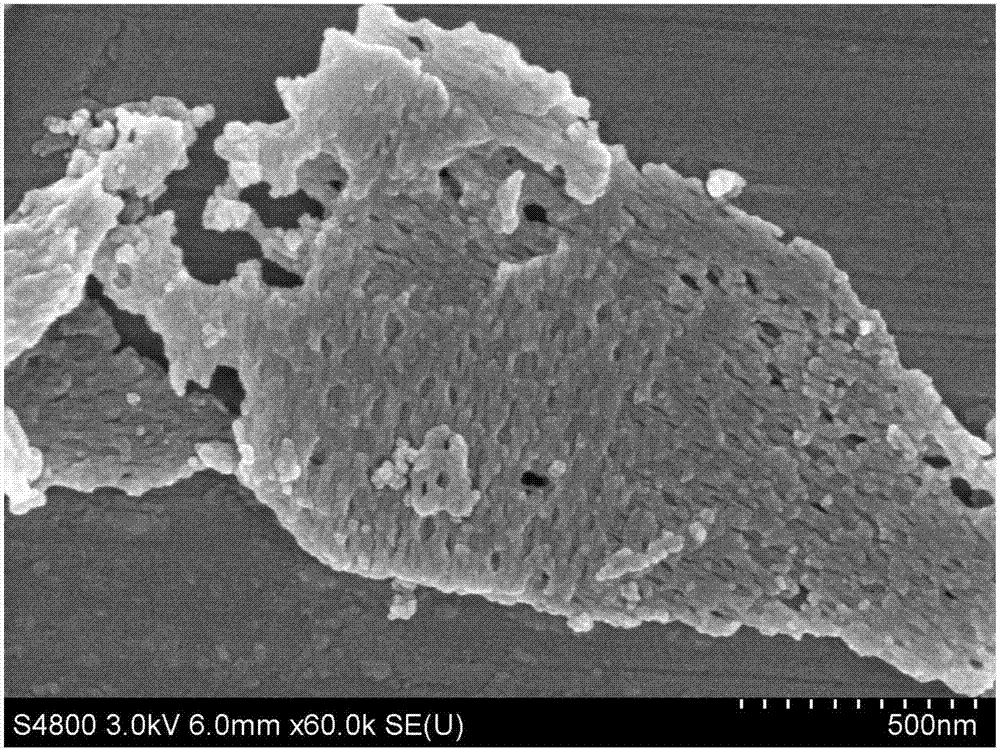

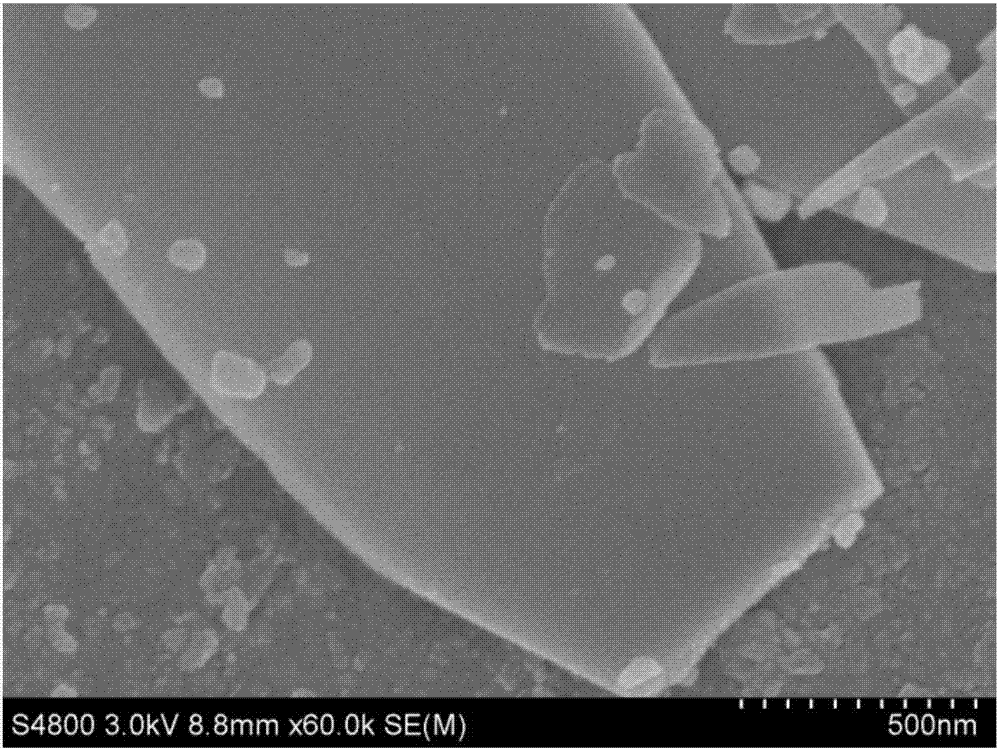

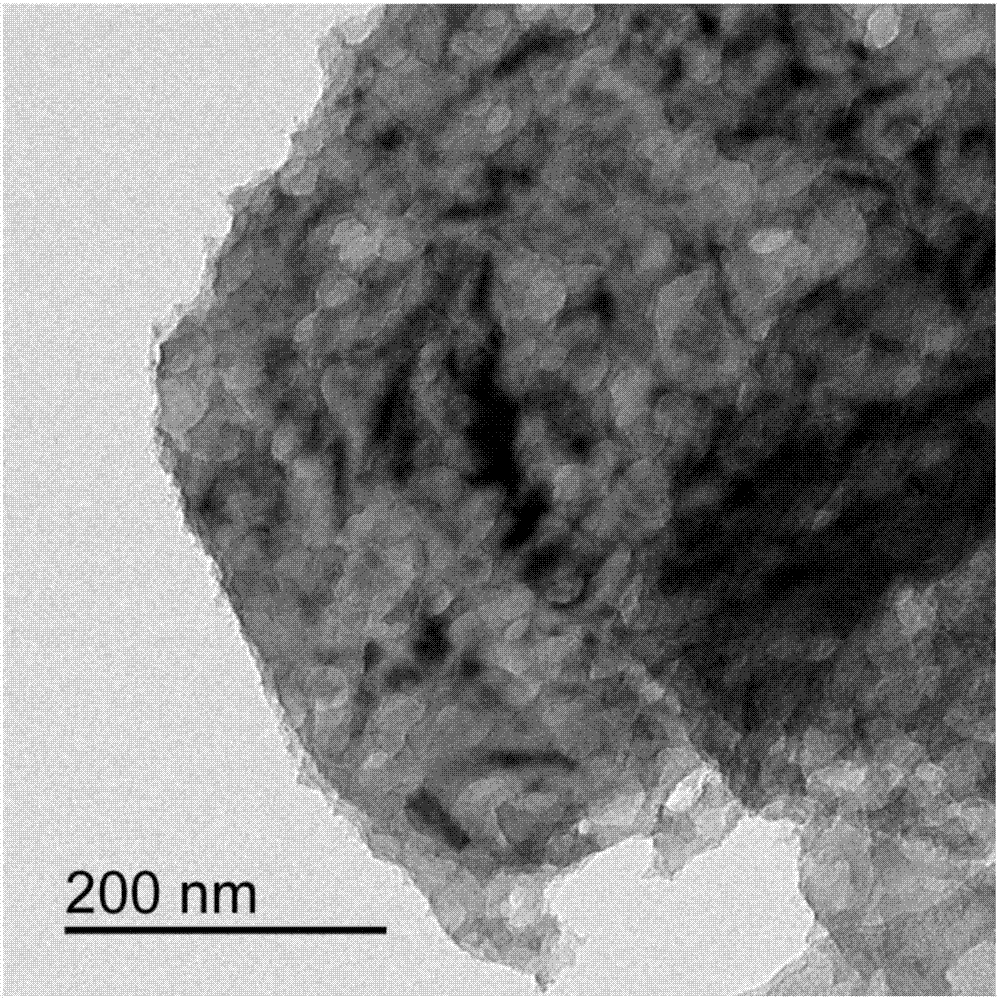

[0027] Step 1: According to the solid-liquid ratio of 0.5g: 30mL, the layered structure titanate H 1.07 Ti 1.73 o 4 Particles are added to Ba(OH) with a concentration of 0.05mol / L 2 The aqueous solution was hydrothermally treated at 105°C for 6 hours, filtered, washed, and dried at 50°C to obtain a white powder.

[0028] Step 2: Add the white powder obtained in Step 1 into 100 mL of dilute HCl solution with a concentration of 0.1 mol / L, stir for 2 hours, filter, wash, and dry at 50°C to finally obtain titanic acid with a porous layered structure particle.

Embodiment 2

[0030] Step 1: According to the solid-liquid ratio of 1g:30mL, the layered structure titanate H 1.07 Ti 1.73 o 4 Particles were added to 30mL of Ba(OH) with a concentration of 0.05mol / L 2 The aqueous solution was hydrothermally treated at 105°C for 6 hours, filtered, washed, and dried at 50°C to obtain a white powder.

[0031] Step 2: Add the white powder obtained in Step 1 into 100 mL of dilute HCl solution with a concentration of 0.5 mol / L, stir for 2 hours, filter, wash, and dry at 50°C to finally obtain titanic acid with a porous layered structure particle.

Embodiment 3

[0033] Step 1: According to the solid-liquid ratio of 1g:30mL, the layered structure titanate H 1.07 Ti 1.73 o 4 Particles were added to 30mL of Ba(OH) with a concentration of 0.1mol / L 2 The aqueous solution was hydrothermally treated at 120°C for 6 hours, filtered, washed, and dried at 50°C to obtain a white powder.

[0034] Step 2: Add the white powder obtained in Step 1 into 200 mL of dilute HCl solution with a concentration of 1 mol / L, stir for 6 hours, filter, wash, and dry at 50°C to finally obtain titanic acid particles with a porous layered structure .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com