An automatic feeding lead ingot decontamination tablet pressing device

A technology of automatic feeding and lead ingots, applied in heating devices, workpiece cleaning devices, transportation and packaging, etc., can solve problems such as affecting the quality of batteries, and achieve the effect of clear thinking, saving personnel, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

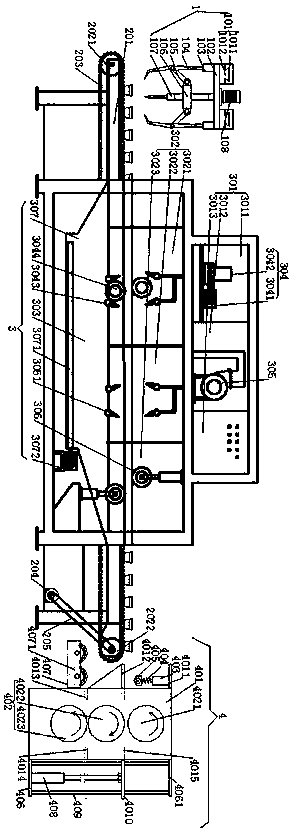

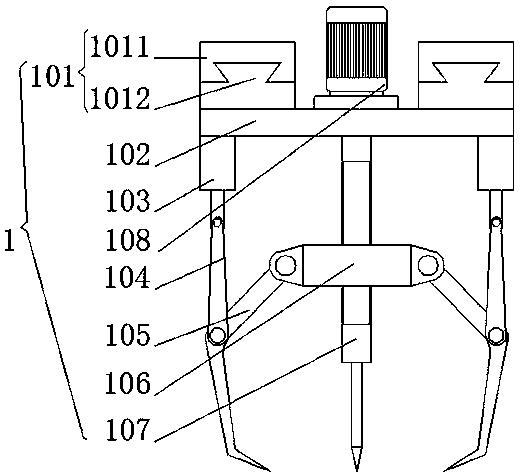

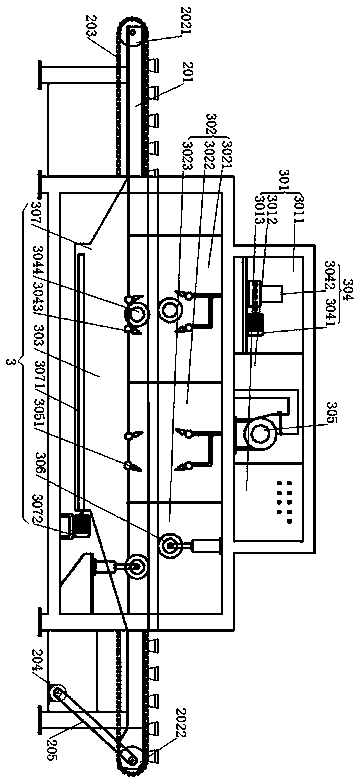

[0022] An automatic feeding lead ingot decontamination tableting device, comprising a feeding system 1, a conveying system 2, a decontamination system 3 and a tableting system 4, the feeding system 1 is composed of a guide rail 101, a hanging plate 102, a stepping Motor 108, cylinder 103, pull arm 104, gripper 105, movable block 106, ejector rod 107 are formed, and described guide rail 101 is made up of guide groove rail 1011 and slide block 1012, and described guide groove rail is fixed on the framework, to all The guide groove rail 1011 is fixed, and the slide block 1012 is installed in the groove of the guide groove rail 1011. The upper plane of the suspension plate 102 is symmetrically connected with the slider 1012, and the edge of the lower plane of the suspension plate 102 is evenly connected with three cylinders 103. The cylinder rod of the cylinder 103 is movably connected to one end of the pull arm 104, and the other end of the pull arm 104 is movably connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com